For more information visit: www.Eaton.com IB01602011E

Instructional Booklet

Page 20 Effective: March 2007

Fixed and Drawout Magnum Transfer Switches

Carefully lower the circuit breaker down onto the extension rails.

Be certain that the circuit breaker’s four molded drawout rail sup-

ports are fully seated in the extension rail cutouts on both sides

(Figure 22). Do not remove the lifting yoke from the circuit

breaker until it is properly seated on the rails.

Once the circuit breaker is on the extension rails and the lifting

yoke is removed, proceed with the rest of the circuit breaker

installation.

4.8 Wiring

Power sources, load conductors, and control wiring should be

connected to locations as indicated in the Customer Wiring Dia-

grams supplied with the transfer switch equipment.

4.8.1 Engine Start Connection

The engine control contact connections are located on the

ATC-600/ATC 800 Controller. The engine control contact con-

nections of bypass isolation units are located in the door of the

enclosure

Note: Prior to making the engine start connection to the switch on bypass

isolation units, set the engine generator controls selector switch in the OFF

position to prevent an unwanted engine start. A contact closes between

these terminal blocks when an engine start signal is provided by the ATS

logic.

4.8.2 ALARM CONTACTS (CLOSED TRANSITION ONLY)

Closed transition only ATSs are provided with an extra shunt trip

on the Source 1 device. This shunt trip is energized when the

Time Delay Utility Parallel (TDUP) times out (preset by user), thus

opening the source device. The TDUP timer starts timing when

both sources are paralleled. Refer to the IQ Transfer instruction

book for additional alarms.

Section 5: Operation

5.1 General

A transfer switch provides main contacts to connect and discon-

nect the load to and from the Source 1 and Source 2 power

sources. A stored-energy type transfer mechanism provides the

mechanical motion required to open and close the main contacts

(Paragraph 3.2.1).

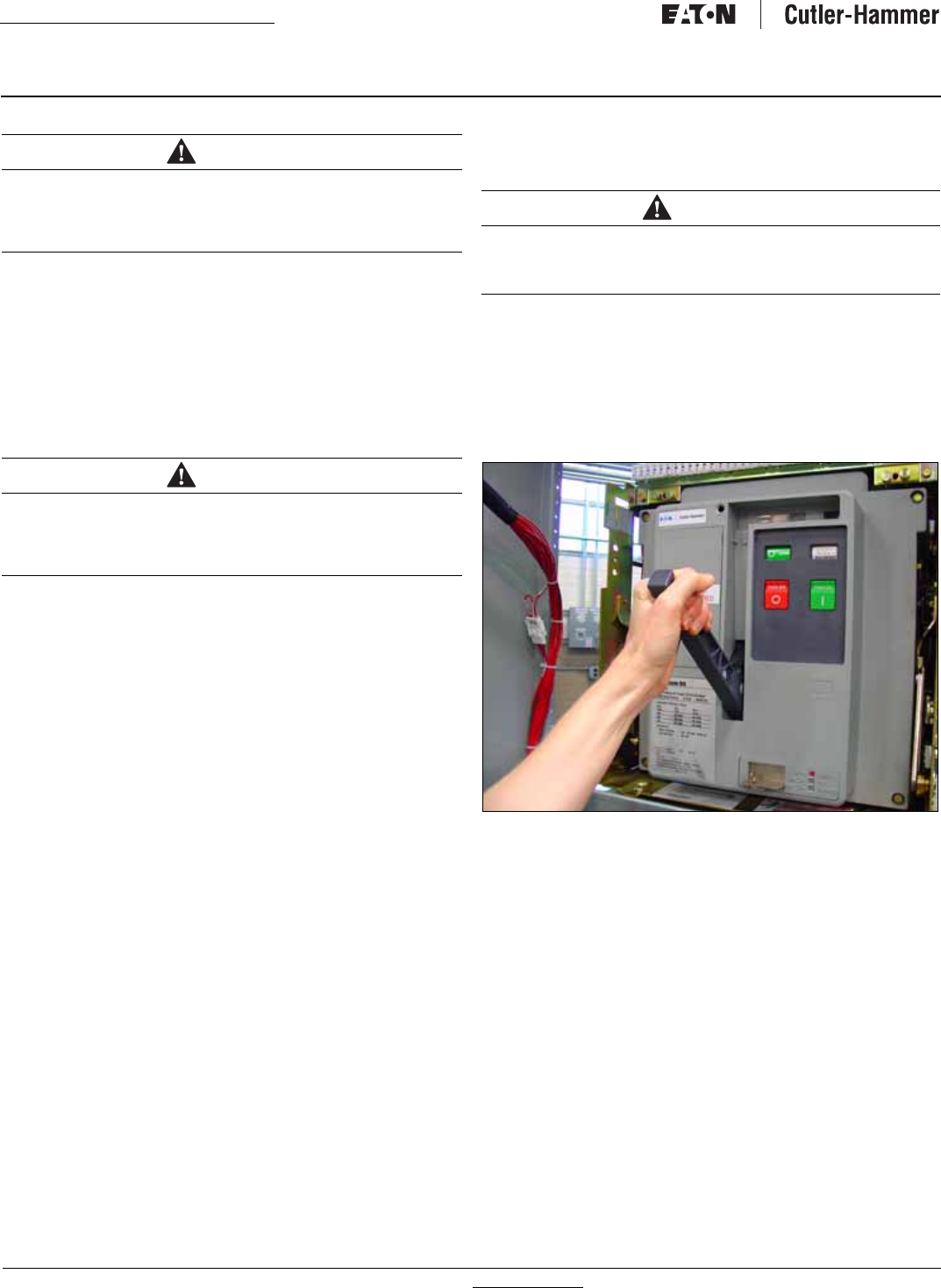

Each switch can be manually operated. Before a switching device

can be closed, the stored energy mechanism must be charged by

pumping the handle (Figure 23).

Figure 23. Pumping Handle Charges Stored Energy Mechanism

(Closed Transition Shown).

In the closed transition product, a single switching device can be

manually closed by following the instructions detailed in Figure

25. An indicator window shows whether the switch is open or

closed.

The open transition switching device can be closed by pushing the

close button (Figure 24). The other switching device is prevented

from closing through a rigid mechanical interlock (Paragraph

3.2.2). An indicator window shows whether the switch is open

or closed.

CAUTION

IT IS IMPORTANT TO TAKE GREAT CARE WHEN PLACING A DRA-

WOUT CIRCUIT BREAKER ON ITS EXTENSION RAILS. IF THE CIR-

CUIT BREAKER IS NOT PROPERLY SEATED ON THE EXTENSION

RAILS, IT COULD FALL FROM THE RAILS CAUSING EQUIPMENT

DAMAGE AND/OR BODILY INJURY.

CAUTION

POWER CONDUCTORS AND CONTROL WIRING MAY HAVE VOLT-

AGE PRESENT THAT CAN CAUSE SEVERE PERSONAL INJURY OR

DEATH. DE-ENERGIZE ALL POWER OR CONTROL CIRCUIT CONDUC-

TORS BEFORE BEGINNING TO PERFORM ANY WIRING ACTIVITY TO

OR WITHIN THE TRANSFER SWITCH EQUIPMENT.

WARNING

THE CLOSED TRANSITION PRODUCT CONTAINS A SPECIAL CON-

TACT ARRANGEMENT (OVERLAPPING CONTACTS). MISUSE CAN

RESULT IN DEATH, SEVERE PERSONAL INJURY, AND/OR PROPERTY

DAMAGE.