53

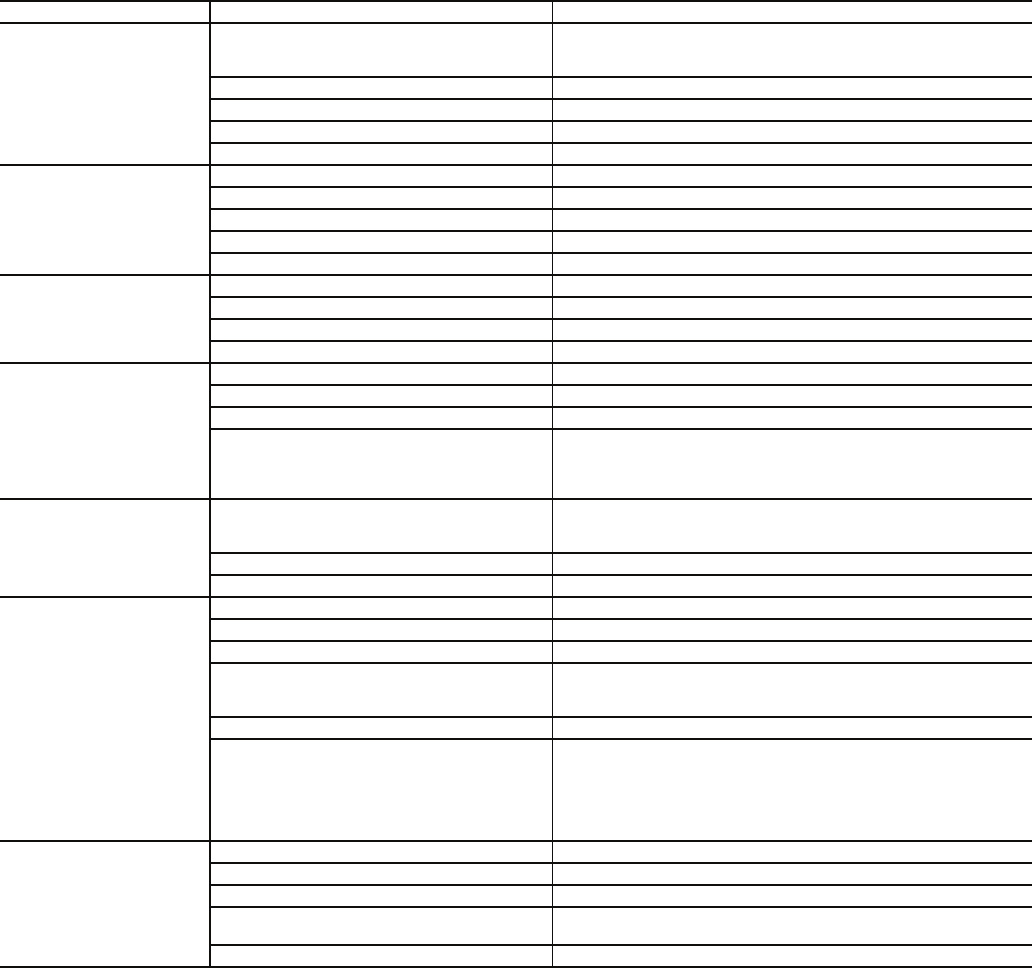

Table 28 — Unit Troubleshooting

LEGEND

PROBLEM POSSIBLE CAUSE CORRECTION PROCEDURE

Unit Will Not Start. Loss of unit power Check power source.

Check fuses, circuit breakers, disconnect switch.

Check electrical contacts.

Unit voltage not correct Check and correct.

Open fuse Check for short circuit in unit.

Open protection device Check relays (phase monitor option), contacts, pressure switches.

Unit or motor contactor out of order Test and replace if necessary.

Fan Does Not Operate. Contactor or relay overload or out of order Test and replace if necessary.

VFD not running Perform VFD diagnostic test.

Motor defective Test and replace if necessary.

Broken belt Replace belt.

Loose electrical contact Tighten contact.

Compressor is Noisy, But

Will Not Start.

Under voltage Check and correct.

Defect in compressor motor Replace compressor.

Missing phase Check and correct.

Compressor seized Check and replace if necessary.

Compressor Starts,

But Does Not Continue

to Run.

Compressor or contact defect Test and replace if necessary.

Unit is under charged Check and correct any leaks. Add refrigerant.

Unit is too big Check load calculation.

Compressor is overloaded Check protection device and replace.

Check for missing phase.

Check TXV.

Check temperature in suction discharge line.

Unit is Noisy. Compressor noise Check TXV and replace if necessary.

Compressor rotation incorrect; check and correct.

Check internal noise.

Tube vibration or condenser water problem Check and correct.

Unit panel or part vibrating Check and tighten appropriate part.

Unit Runs Continuously,

But Has Low Capacity.

Unit is too small Check load calculation.

Low refrigerant or noncondensing gas present Check for leaks and add refrigerant or gas as necessary.

Compressor defect Check pressure and amps. Replace if necessary.

Insufficient flow of refrigerant in evaporator Check filter drier and replace if necessary.

Check TXV and adjust or replace if necessary.

Check position of TXV bulb and equalizer.

Oil in evaporator Drain evaporator.

Low airflow Check filters, and clean or replace as necessary.

Check coils, and clean as necessary.

Check for restrictions in ductwork.

Check fan rotation and adjust.

Check fan motor.

Check belts for wear.

High Discharge Pressure. Low waterflow in condenser Purge air.

Dirty condenser tubes. Clean condenser.

High temperature in condenser water Check water tower fans and pumps.

Overcharged Check and reclaim excess charge.

Adjust subcooling.

Noncondensing gas present Verify and correct.

TXV — Thermostatic Expansion Valve

VFD — Variable Frequency Drive