51

Evaporator Fan Performance Adjustment —

To change fan speeds from factory settings:

1. Shut off unit power supply.

2. Loosen nuts on the 4 carriage bolts in the mounting

base. Using adjusting bolts and plate, slide the motor

and remove the belt.

3. Loosen movable-pulley flange setscrew.

4. Screw the movable flange toward the fixed flange to

increase speed, and away from the fixed flange to

decrease speed. Increasing the fan speed increases the

load on the motor. Do not exceed the maximum speed

specified in Tables 3A and 3B.

5. Set the movable flange at nearest keyway of the pulley

hub and tighten the setscrew. (See Tables 3A and 3B

for speed change for each full turn of pulley flange.)

6. Replace and tighten the belts (see Belt Tension Adjust-

ment section).

7. Restore power to the unit.

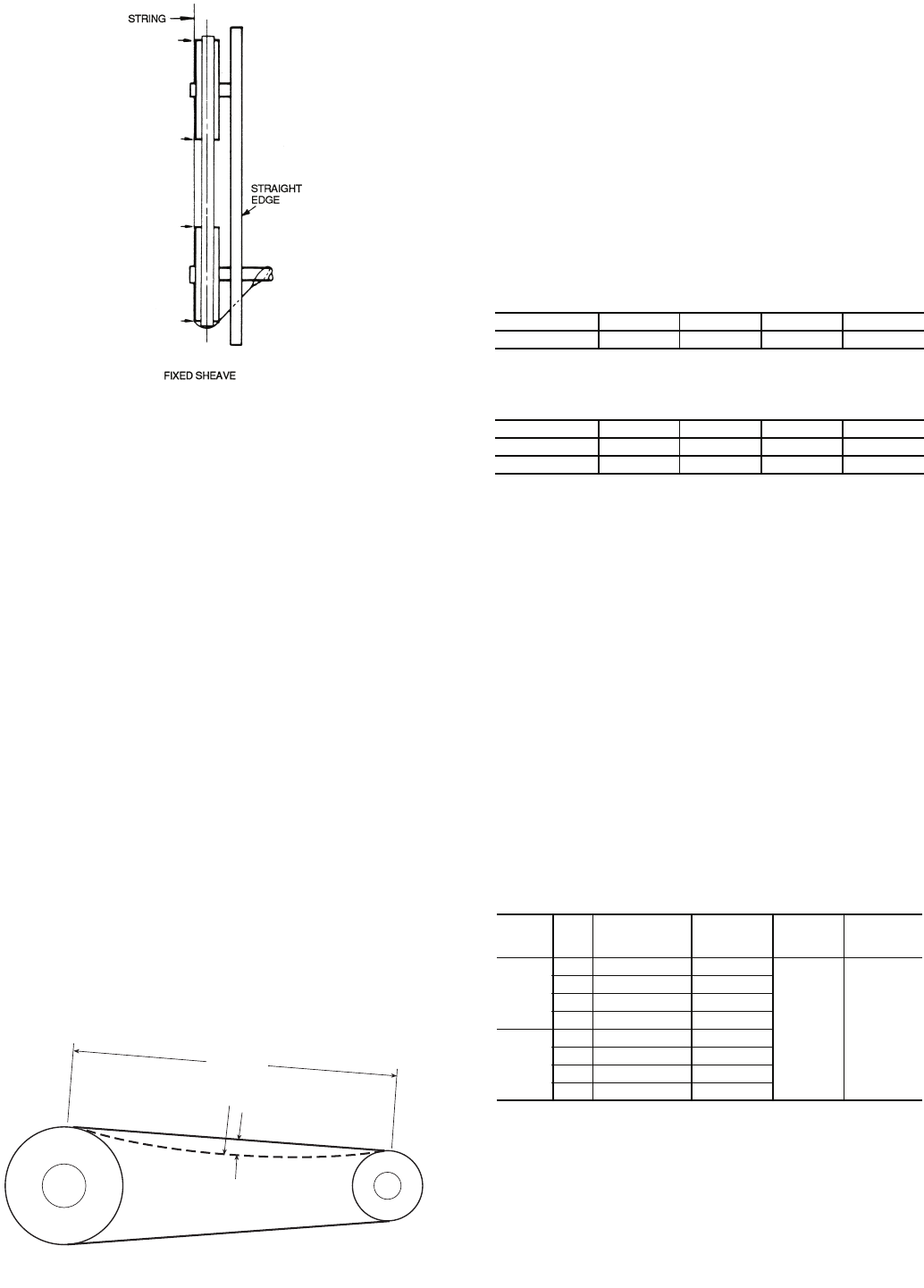

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from

mounting plate.

4. Restore power to unit.

BELT TENSION ADJUSTMENT — Using a gage, apply

4 lb of force to the center of the belt and adjust the tension until

a deflection of

1

/

64

-in. is achieved for every inch of shaft center

distance. See Fig. 37.

Ideal belt tension is the lowest value under which belt slip

will not occur at peak load conditions.

Charging the System

REMOTE AIR-COOLED UNITS — The 50BVE,K,U,X units

are shipped with a holding charge of dry nitrogen. Remote

condensers, interconnecting piping, and refrigerant to charge the

system are all field supplied.

To evacuate the system, refer to GTAC II, Module 4, Dehy-

dration for Proper Evacuation and Dehydration Techniques.

To charge the 50BVE,K,U,X systems:

1. Add an initial minimum refrigerant charge after evacu-

ation to allow the unit to start. Refer to Tables 25A and

25B. Additional refrigerant will be added based on the

length of interconnecting piping and vertical separa-

tion between the indoor unit and the condenser(s).

Table 25A — Minimum Operating Charge (lb),

50BVE,K Units Matched with 09DK Condensers

Table 25B — Minimum Operating Charge (lb),

50BVU,X Units Matched with 09DK Condensers

2. To finish charging the system, make sure the unit

is running at full-load operating conditions. Charge to

a clear sight glass. Refer to GTAC II, Module 5,

Charging, Recovery, Recycling and Reclamation and

the Refrigerant Service Techniques manual for proper

charging techniques.

3. Add 10 lb of R-22 or R-410A over a clear sight glass

to flood subcooler section of the condenser coils.

4. Alternately, and as a double-check, when properly

charged at full-load operating conditions, there should

be 15 F subcooling entering the TXV (the difference

between saturated condenser temperature and actual

liquid temperature entering the TXV).

Compressor Oil — All units are factory charged with

oil. It is not necessary to add oil unless compressor(s) is re-

moved from the unit. If necessary, oil can be removed/charged

via Schrader fitting. Operate the system at high evaporator tem-

perature prior to oil recharge to assist oil return to the compres-

sor(s) from other system components. If necessary, recharge

the system as shown in Table 26.

Table 26 — Oil Recharge

TROUBLESHOOTING

Refer to Tables 27-29 to determine the possible cause of the

problem and the associated procedure necessary to correct it.

See Fig. 38-47 for unit and control wiring.

UNIT SIZE 020 024 028 034

Circuit 1...2 8.1...8.1 9.1...9.1 9.1...9.1 18...18

UNIT SIZE 034 044 054 064

Circuit 1...2 18...18 10...10 18...18 18...18

Circuit 3...4 - 10...10 18...18 18...18

50BV

UNIT

SIZE COMPRESSOR

OIL

RECHARGE

(oz)

OIL

TYPE

PART

NUMBER

C,E,

Q,J,K

020 ZR94KC 81

3GS 150

viscosity

yellow

mineral

oil

P903-0101

024 ZR108KC 106

028 ZR144KC 106

034 ZR19M3 137

T,U,

V,W,X

034 ZR19M3 137

044 ZR125KC 106

054 ZR16M3 137

064 ZR19M3 137

BELT SPAN

LB FORCE

DEFLECTION

Fig. 37 — Fan Belt Tension

a50-7136ef

Fig. 36 — Sheave Alignment

a50-7135tf