24

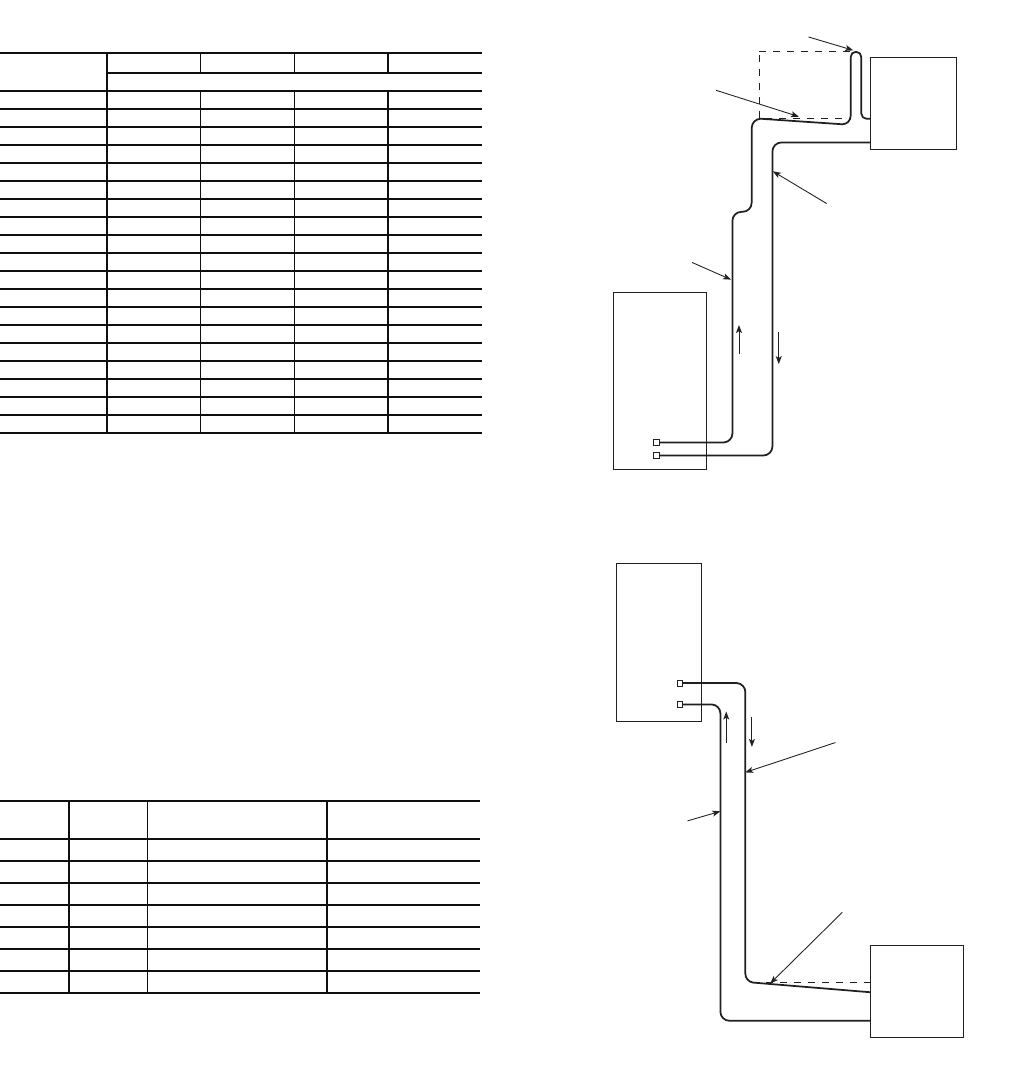

Table 7B — Economizer Pressure Drop Curve

(ft wg), 50BVT,U,V,W,X Units

LEGEND

REMOTE REFRIGERANT PIPING (Remote Air-Cooled

Only) — Carrier 50BVE,K,U,X units are supplied without

condensers. To complete the installation, these units must be

field connected to a suitable remote condenser. The 50BV units

from 18 to 30 tons contain 2 equally sized independent refriger-

ant circuits. Units from 40 to 60 tons have 4 separate equal ca-

pacity refrigerant circuits. It is important that the condenser cir-

cuiting be properly matched to the 50BV unit circuiting. Other-

wise, unsatisfactory operation will result. Carrier will not be

responsible for improperly matched remote condenser selec-

tions. Recommended condenser matches are shown in Table 8.

Table 8 — Recommended Condenser Matches

for 50BVE,K,U,X Units

Install the air-cooled condenser or condensers according to

the installation instructions provided with the condenser(s).

Connection locations and sizes for the hot gas and liquid lines

on the 50BV units are shown in Fig. 2-14, 22 and 23. For

50BV units up to 30 tons, there will be 2 hot gas lines and 2 liq-

uid lines to install between the unit and the condenser. Above

30 tons, 4 hot gas lines and 4 liquid lines will be installed be-

tween the unit and the 2 condensers. Refer to the System De-

sign Manual, Part 3 for standard refrigerant piping techniques.

Also see the air-cooled condenser installation instructions for

additional guidance.

Remote air-cooled 50BV units (only) are shipped with a dry

nitrogen holding charge. After refrigerant connections are

made, release nitrogen, evacuate, leak test, and charge the

system as described in Charging the System in the Mainte-

nance section of this manual.

Step 5 — Complete Electrical Connections —

Verify that electrical requirements listed on the unit nameplate

match available power supply. The unit voltage must be within

the range shown in Tables 9A and 9B and phases must be

balanced within 2%. Contact the local power company for line

voltage corrections. Never operate a motor where a phase im-

balance in supply voltage is greater than 2%.

FLOW RATE

(gpm)

SIZE 034 SIZE 044 SIZE 054 SIZE 064

Pressure Drop (ft wg)

60 13.1 — — —

70 17.9 — — —

80 23.5 5.8 — —

90 29.8 7.3 — —

100 36.9 9.1 9.0 —

110 44.8 11.0 11.0 —

120 53.4 13.1 13.1 13.1

130 — 15.4 15.4 15.4

140 — 17.9 17.9 17.9

150 — 20.6 20.6 20.6

160 — 23.5 23.5 23.5

170 — — 26.6 26.5

180 — — 29.8 29.8

190 — — 33.3 33.2

200 — — 36.9 36.8

210 ———40.7

220 ———44.7

230 ———48.9

240 ———53.3

GPM — Flow Rate

PD — Pressure Drop (ft wg)

50BV

NO. OF

CKTS

CONDENSER(S)

CONDENSER

CIRCUITING

020 2 09DK020 (1) 50/50%

024 2 09DK024 (1) 50/50%

028 2 09DK028 (1) 50/50%

034 2 09DK034 (1) 50/50%

044 4 09DK024 (2) 50/50% (each)

054 4 09DK028 (2) 50/50% (each)

064 4 09DK034 (2) 50/50% (each)

LIQUID

LINE

SLOPE

TOWARD

CONDENSER

TRAP (MUST BE

ABOVE TOP OF

CONDENSER COIL)

REMOTE

CONDENSER

HOT GAS

LINE

50BV

UNIT

Fig. 22 — System with Condenser

Above Evaporator

a50-7270ef

50BV

UNIT

REMOTE

CONDENSER

HOT GAS

LINE

LIQUID

LINE

SLOPE TOWARD

CONDENSER

a50-7271ef

Fig. 23 — System with Evaporator

Above Condenser