21

Step 4 — Make Piping Connections

CONDENSER WATER PIPING (Water-Cooled Only) —

Always follow national and local codes when installing water

piping to ensure a safe and proper installation. Connections to

the unit should incorporate vibration eliminators to reduce

noise and vibration to the building, and shutoff valves to facili-

tate servicing.

Prior to connecting the unit(s) to the condenser water

system, the system should be flushed to remove foreign

material that could cause condenser fouling. Install a screen

strainer with a minimum of 20 mesh ahead of the condenser

inlet to prevent condenser fouling and internal condenser tube

damage from foreign material.

Supply and return water piping must be at least as large as

the unit connections, and larger for long runs. Refer to the

System Design Manual, Part 3, and standard piping practice,

when sizing, planning, and routing water piping. See dimen-

sion drawings (Fig. 2-14) for water connection sizes and

locations.

Units are furnished standard with a copper heat exchanger.

A cupronickel heat exchanger is also available as a

factory-installed option. Copper is adequate for closed loop

systems where good quality water is available. In conditions

where scale formation or water treatment is questionable, the

optional cupronickel heat exchanger should be used. Where the

water is especially corrosive or could lead to excessive fouling,

intermediate plate frame heat exchangers are recommended.

The unit is capable of operating with entering water temper-

atures as low as 50 F, without the need for head pressure

control. If the entering water temperature is expected to be

lower, or more stable unit operation is desired, a field-supplied

water-regulating valve may be used.

This unit has multiple independent refrigerant circuits with

separate condensers. The individual condensers are manifolded

together on the waterside to provide easy, single-point water

connections. In order to achieve proper head pressure control

when a water-regulating valve is used, a temperature-actuated

valve is recommended. This allows any of the independent

refrigerant circuits to operate while still modulating condenser

water flow in response to loop water temperature.

A glycol solution should be used if ambient temperatures

are expected to fall below freezing or if the loop water temper-

ature is below 50 F while operating in the reverse cycle heating

mode (heat pump units only). Refer to Table 4, which

lists freezing points of glycol at different concentrations. A

minimum concentration of 20% is recommended. Water

pressure drop will increase and unit performance will decrease

with increasing glycol concentrations.

Units with factory-installed waterside economizers have

cooling water passing through the economizer and condenser

in series while operating in the economizer mode. During

normal operation, water bypasses the economizer coil.

Table 4 — Glycol Freezing Points

All manual flow valves used in the system should be of the

ball valve design. Globe or gate valves must not be used due to

high pressure drops and poor throttling characteristics.

Do not exceed recommended condenser fluid flow rates

shown in Tables 5A and 5B. Serious damage or erosion of the

heat exchanger tubes could occur. Piping systems should not

exceed 10 fps fluid velocities to ensure quietness and tube wall

integrity. Refer to Tables 5A and 5B for condenser water pres-

sure drop versus flow rate. Flow rates outside of the published

range should not be used.

Ball valves should be installed in the supply and return lines

for unit isolation and water flow balancing.

CAUTION

Galvanized pipe or fittings are not recommended with

50BV units due to the possibility of galvanic corrosion

caused by dissimilar metals. When selecting piping

materials, use only approved piping materials that meet

applicable codes and that will handle the temperatures and

pressures that may be experienced in the application.

Piping systems will sweat if low temperature fluid is used

in the system. For these applications, supply and return

water piping should be insulated to protect from condensa-

tion damage. The minimum recommended entering water

temperature to the unit is 50 F.

% GLYCOL

FREEZE POINT (° F)

Ethylene Glycol Proplylene Glycol

20 18 19

30 79

40 –7 –5

50 –28 –27

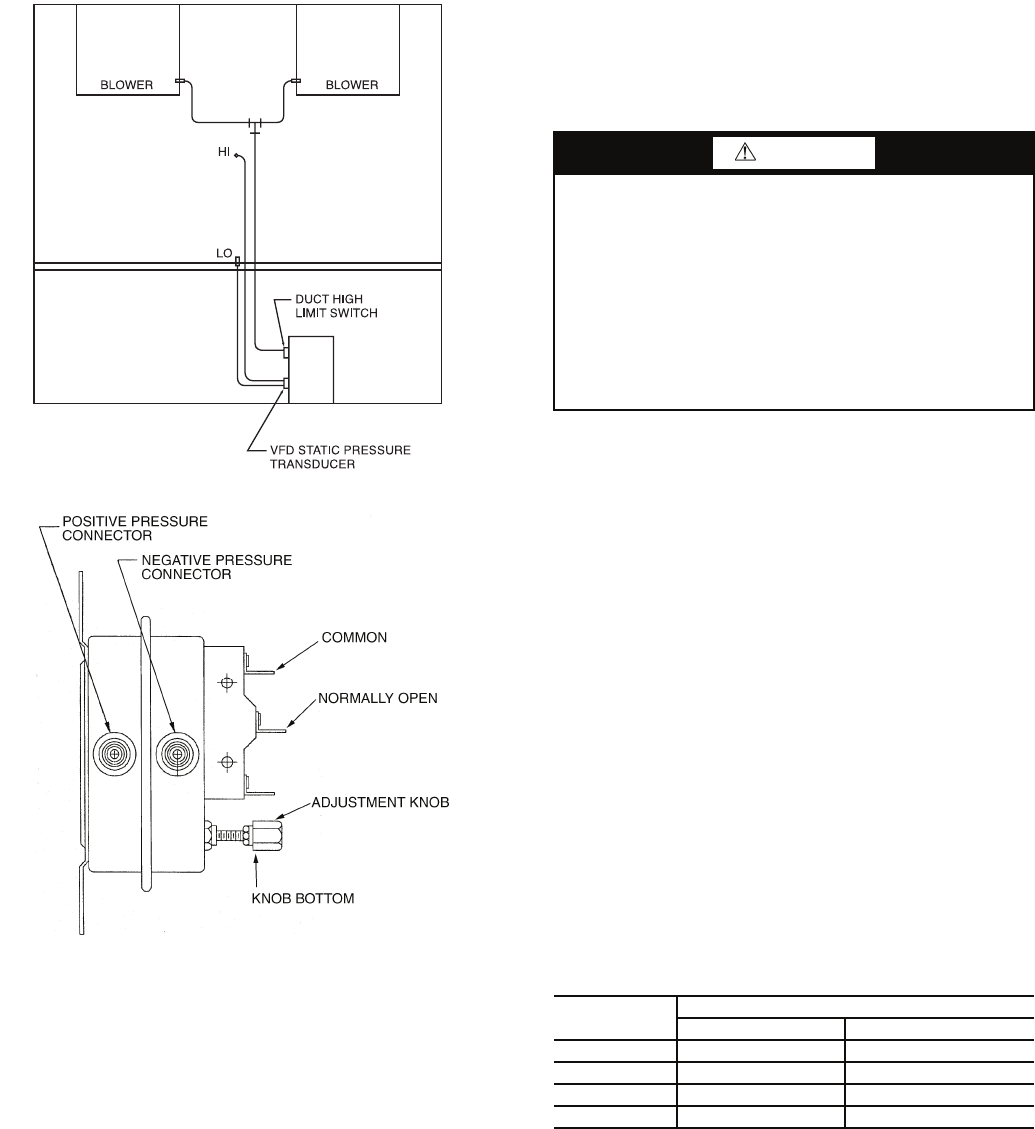

Fig. 19 — DHS Limit Switch (P/N 190060)

a50-7268tf

Fig. 18 — DHS Pressure Limit Location

a50-8253