20

acceptable system static pressure. If the existing duct system is

too small, larger ductwork must be installed.

The duct system and diffusers should be sized to handle the

design airflow volumes quietly. To maximize sound attenuation

of the unit's blower(s), the supply and return air plenums should

be insulated for a length of at least 15 ft from the unit. Direct line

of sight from return air grilles into the unit's return should be

avoided. If return air is to be ducted to an equipment room, an

elbow should be installed within the equipment room. Running a

return air drop to near the floor of the room will aid in sound

attenuation. Avoid transmitting vibrations generated by the

movement of air in the ducting to the walls of the building. This

is especially important where ductwork penetrates walls. The

maximum recommended return air velocity is 1,000 fpm. Lower

return air velocities will result in lower sound power levels. The

use of round supply duct plenums should be considered, as it

will significantly reduce low frequency sound at the equipment

room. If rectangular supply plenums are used, the aspect ratio of

the duct should be kept as small as possible (i.e., as close to

square as possible). The large, flat surface areas associated with

large aspect ratio duct systems will transmit sound to the space,

and the potential for duct-generated noise is increased. The max-

imum recommended supply air duct velocity is 2,000 fpm.

Units with two fans should have a properly designed “pair

of pants” duct connection. An adequate straight length of

ducting from the unit should be allowed before elbows are

installed. If connecting an elbow directly to the fan outlet, a

minimum straight length of 2 fan diameters from the fan outlet

is recommended. Elbows should turn in the direction of fan ro-

tation, if possible. Abrupt turns will generate air turbulence and

excessive noise. Turning vanes should be used in all short radi-

us bends. Ensure that ducting does not obstruct access to the

unit for routine servicing.

DUCT STATIC PRESSURE PROBE AND TUBING (VAV

Only) — On VAV systems, the duct static pressure sensor and

tubing are field-mounted. The sensor tubing sensing point

should be located near the end of the main supply trunk duct in

a position free from turbulence effects and at least 10 duct di-

ameters downstream and 4 duct diameters upstream from any

major transitions or branch take-offs. Incorrectly placing the

sensing point could result in improper operation of the entire

VAV sys te m.

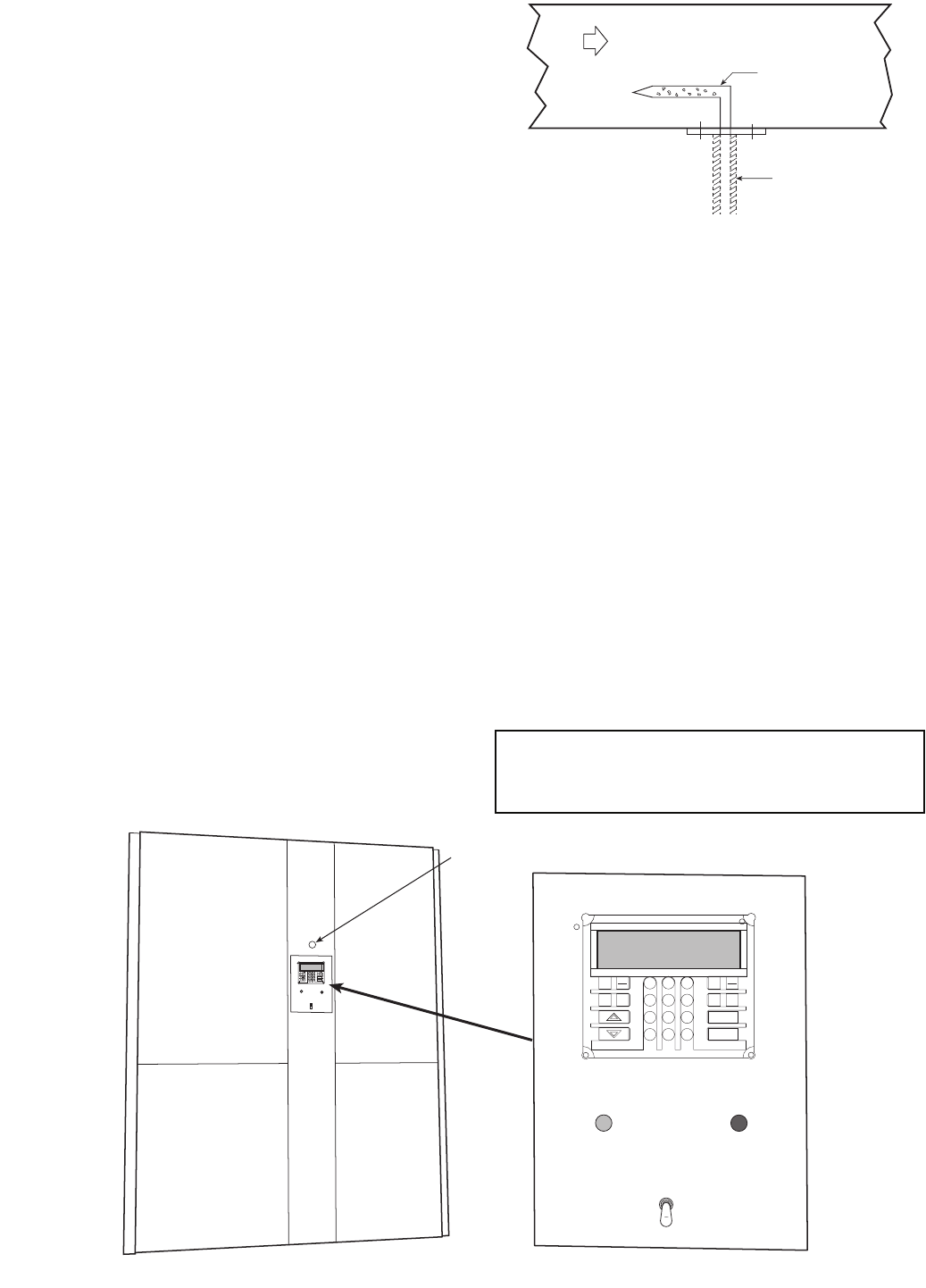

Install the factory-supplied duct static pressure probe with

the tip facing into the airflow. See Fig. 16.

Use

1

/

4

-in. OD approved polyethylene tubing for up to

50 ft (

3

/

8

-in. OD for 50 to 100 ft) to connect the probe to the

bulkhead fitting mounted above the unit display panel

(Fig. 17). Carefully route the tubing from the probe to this

bulkhead fitting.

The static pressure control should be adjusted so that, at full

airflow, all of the remote VAV terminal boxes receive the

minimum static pressure required plus any downstream resis-

tance. Control the system to the lowest static pressure set point

that will satisfy airflow requirements. Lower static pressure set

points reduce total required brake horsepower and reduce

generated sound levels.

DUCT HIGH-STATIC (DHS) LIMIT SWITCH (VAV

Only) — The duct high static limit switch is a mechanical

safety that prevents duct overpressurization. The switch is lo-

cated on the side of the VAV low voltage control panel

(Fig. 18) and is factory set at 3 in. wg. To make an adjustment

using an accurate differential pressure gage, connect low side

and high side to gage and pressure source. Place a voltmeter

across common and normally open contacts. Rotate the adjust-

ment knob (Fig. 19) clockwise to increase pressure setting and

counterclockwise to decrease pressure setting. When the bot-

tom of the adjustment knob is approximately

1

/

8

-in. from the

switch body, the switch will trip at approximately 3 in. wg.

IMPORTANT: Use tubing that complies with local codes.

Improper location or installation of the supply duct pres-

sure tubing will result in unsatisfactory unit operation and

poor performance.

AIRFLOW

PROBE

TUBING

Fig. 16 — Duct Static Pressure Probe

(P/N 39EK20462)

a50-7138ef

WARNING

ALARM

REMOTE

LOCAL

OFF

ENTER

CLEAR

SRVC

HISTALGO

TEST

ALRM

3

6

9

1

2

4

5

7

8

0

.

–

STAT

SET

SCHD

EXPN

EDIT

WARNING

ALARM

REMOTE

LOCAL

OFF

ENTER

CLEAR

SRVC

HIST ALGO

TEST

ALRM

3

6

9

1

2

4

5

7

8

0

.

–

STAT

SET

SCHD

EXPN

EDIT

DUCT STATIC

PRESSURE

PROBE

BULKHEAD

FITTING

Fig. 17 — Display Panel Location on Unit Front Panel

a50-7267ef