47

DISPLAY ALARM HISTORY — If the controller is indicat-

ing there are alarms, the user can view the alarm history by

pressing the button. The LID display will show “Alarm

History.” Press . The LID display will show the date

and type of alarm.

As an example, if the LID display shows:

ALARM — 10:55 02-11-04

SFS

That display indicates that on 02-11-04 at 10:55 a.m. the

supply fan was either on when it had not been commanded on

or was off when it was commanded on.

The user can view other stored alarms by pressing the up and

down arrows. The twenty-four most recent alarms are stored.

CONFIGURE CUSTOM PROGRAMMING SELEC-

TIONS — To configure the custom programming selections,

perform the following procedure:

1. Press 37 . The LID display will show:

Custom Program

2. Press . The LID display will show:

2.0 Global Dictionary

OMNIZONE

3. Press . The display indicates “No Data.” Press

then press . Press again.

The LID display should now show:

Compressor Stages

2.00 (sizes 020-034)

4.00 (sizes 044-064)

4. Press 7 times. The display will show:

0 = RAT, 1 = MAT 2 = NONE

0.00

5. Press 2 then . The display will show:

0 = RAT, 1 = MAT 2 = NONE

2.00

6. If RAS is installed at EWT input, press

3 times.

The display will show:

EWT Reset 0 = NO, 1 = YES

0.00

7. Press 1 then . The display will now show:

EWT Reset 0 - NO, 1 = YES

1.00

8. Use the down and up arrows to select the other configura-

tion parameters as required. See Table 24 for a list of con-

figuration parameters.

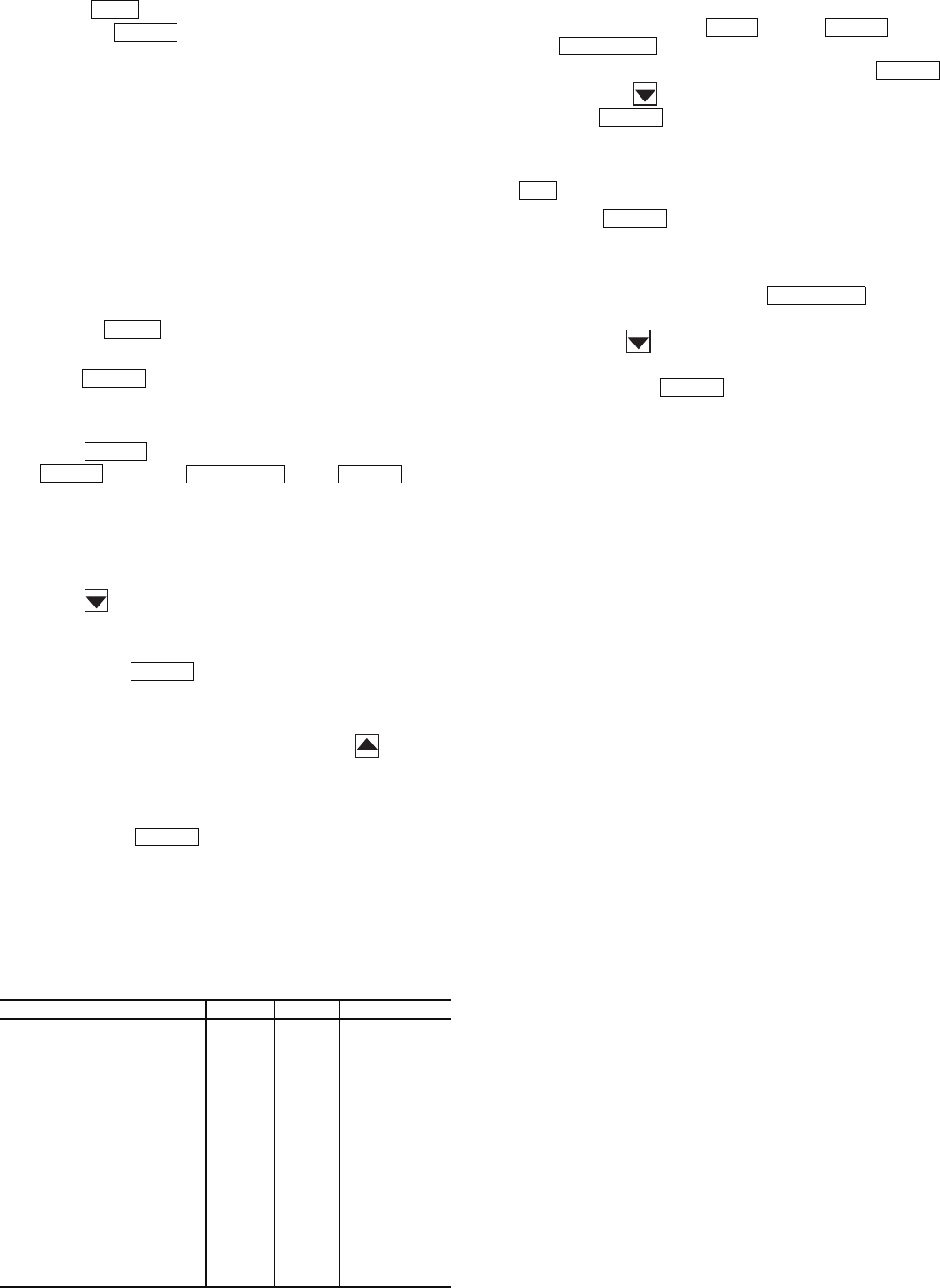

Table 24 — Configuration Parameters

*Not used.

SET CONTROLLER ADDRESS — To set the address of the

Omnizone™ system control panel controller, perform the fol-

lowing procedure:

1. Press 7 and then . Press and then

.

2. Type in the CCN element number and press .

3. Press the button. Type in the CCN bus number and

press .

LOG OFF FROM CONTROLLER — To log off from the

OMNIZONE system control panel controller Press 3 and then

. The controller password will be displayed.

1. Press . The display should show:

Log in to Controller

Logged in

If this is not displayed, Press until it is dis-

played.

2. Press the button. The LID display will show:

Log out of Controller

Press 1. Press to log off.

Sequence of Operation (CV Only) — The follow-

ing sequence applies to constant volume units only.

Cooling is initiated when the set point in the remote thermo-

stat is not met (space temperature is higher than set point). The

unit sequence of operation is as follows:

The 50BV units can be remotely authorized to be controlled

by the thermostat through the optional energy management

system relay (EMS). The coil is powered by the energy man-

agement (building automation) system whose contacts are in

series with the ‘R’ 24-v ac terminal with potential across ‘C’

(transformer common). With this terminal open, power will be

interrupted to the thermostat. Closure of this contact will allow

the 50BV unit to operate from the thermostat.

Contact closure at the ‘G’ terminal will provide power to

the supply fan contactor, energizing the supply fan. The supply

fan will be off during unoccupied schedule, depending upon

the features of the thermostat used. The ‘O’ terminal energizes

the reversing valve (heat pump units only). Typically ‘Y1’ will

also be energized at this time for cooling operation. During the

second stage of cooling, ‘Y2’ will be initialized after a mini-

mum run time and after there is a differential from set point

plus a deadband or a proportional plus integral calculation,

which is based upon demand and the length of time space-

temperature is greater than set point. Additional assurance is

provided by a delay on make timer in the second stage com-

pressor contactor circuit to avoid dual compressor in-rush start-

ing current.

For 4 compressor units, a call for the first stage of cooling

will turn on compressors 1 and 2. The second stage of cooling

will turn on compressors 3 and 4.

Heating mode (heat pump models only) follows the same

sequence as above except that the reversing valve is not

energized.

WATER ECONOMIZER COOLING — The unit diverts

condenser inlet waterflow through an optional economizer coil

to precool evaporator entering airflow. If the entering water

temperature is colder than the setting on the aquastat, and the

return-air temperature is warmer than the setting on the return-

air thermostat, the 3-way diverting valve will direct water to

the economizer coil.

Economizer water flow is in series with the condensers

allowing compressor operation while the economizer is

operating.

DESCRIPTION VALUE UNITS NAME

Compressor Stages 2.00 NUM_CMP

Reset Ratio 3.00 dF RSET_RTO

CDWF 0=NO,1=YES 0.00 CDFW_SWT

*ECON 0=NO,1=YES 0.00 EWT_SNS

EWT Reset 0=NO,1=YES 0.00 EWT_RST

*MOD.VLV 0=NO,1=YES 0.00 MOD_ECON

*0=CONST.,1=VARIABLE 0.00 FLOW_TYP

0=RAT,1=MAT 2=NONE 2.00 MARA_SNS

PHASE 0=NO,1=YES 0.00 PHAS_SWT

*FREEZ 0=NO,1=YES 0.00 FREZ_SWT

*ENABLE ECON. 68.00 dF ECON_SET

SPT 0=NO,1=YES 0.00 SPT_SNS

PRES 0=NO,1=YES 0.00 PRES_SNS

TWR 0=NO,1=YES 0.00 TWR_SNS

LWT 0=NO,1=YES 0.00 LWT_SNS

IAQ 0=NO,1=YES 0.00 IAQ_SNS

IRH 0=NO,1=YES 0.00 IRH_SNS

BSP 0=NO,1=YES 0.00 BSP_SNS

BSP Range 1.00 in. H2O BSP_RNG

BSP LOW VALUE –0.50 in. H2O BSP_LOW

HIST

ENTER

ALGO

ENTER

ENTER

CLEAR

EXPN/EDIT ENTER

ENTER

ENTER

SRVC ENTER

EXPN/EDIT

ENTER

ENTER

SET

ENTER

EXPN/EDIT

ENTER