28

Table 10 — Recommended Cables

NOTE: Conductors and drain wire must be at least 20 AWG

(American Wire Gage), stranded, and tinned copper. Individual

conductors must be insulated with PVC, PVC/nylon, vinyl,

Teflon

®

*, or polyethylene. An aluminum/polyester 100% foil

shield and an outer jacket of PVC, PVC/nylon, chrome vinyl,

or Teflon with a minimum operating temperature range of

–20 C to 60 C is required.

The communication bus shields must be tied together at

each system element. If the communication bus is entirely

within one building, the resulting continuous shield must be

connected to ground at only one single point. If the communi-

cation bus cable exits from one building and enters another

building, the shields must be connected to the grounds at a

lightning suppressor in each building (one point only).

Wiring Control Devices

— Standard controls require no field

wiring.

Standard controls for VAV applications include: duct static

pressure (DSP), duct high static limit switch (DHS), compres-

sor status (CSMUX), supply fan start/stop (SF), and supply fan

speed (SPEED).

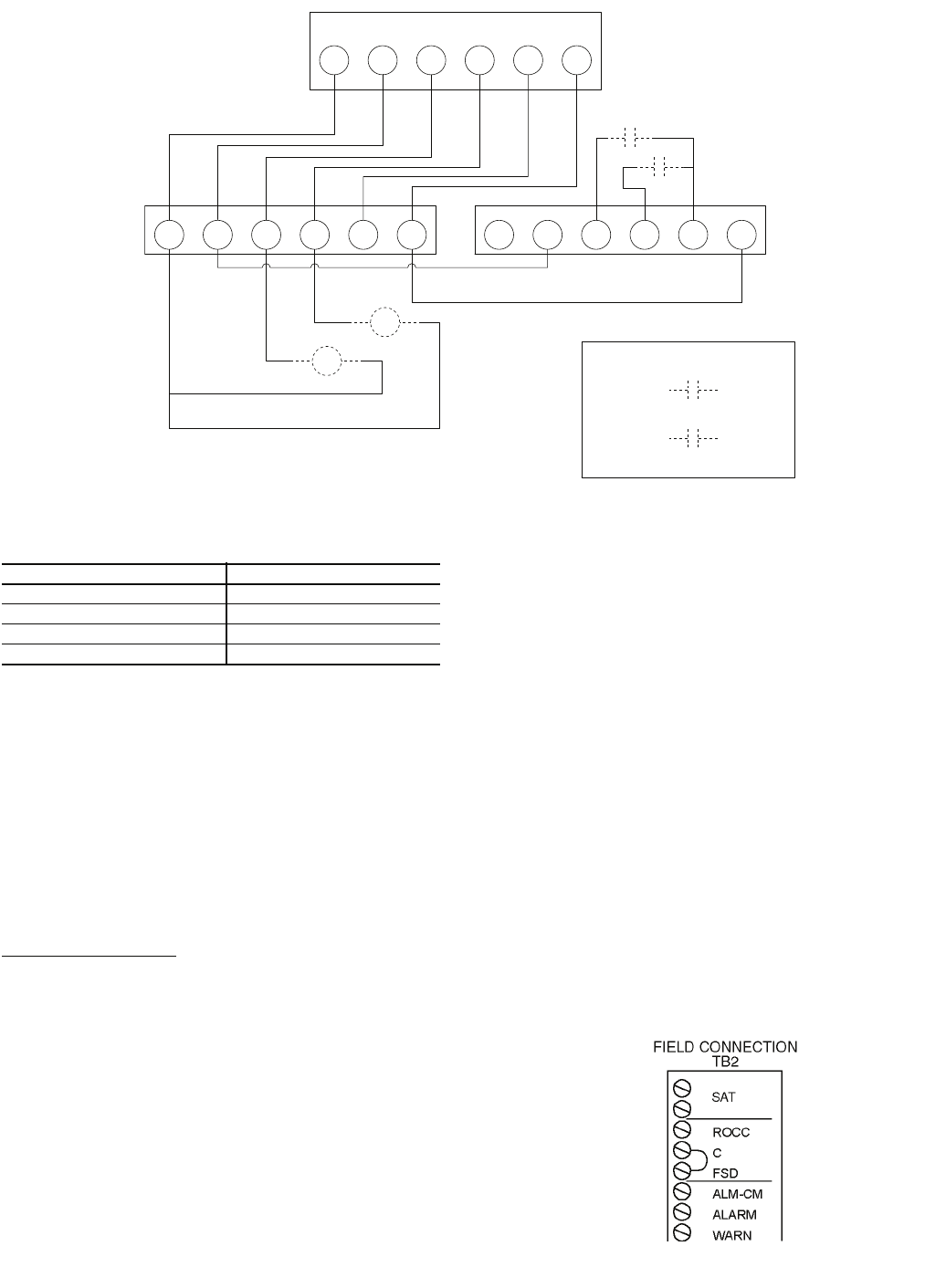

Field-installed devices and the factory-supplied supply air

temperature sensor (required) will be wired to the field termi-

nal block (TB2) provided. Refer to Fig. 26 and the following

descriptions. This terminal is located in the control panel as

shown in Fig. 27 and 28.

SUPPLY AIR TEMPERATURE SENSOR (SAT) — The sup-

ply air temperature sensor (Fig. 29) is used to measure the

temperature of the air leaving the unit. The sensor should be

located in the supply air duct, about 1 ft from the unit discharge

connection (Fig. 30). On units with 2 fans, locate the sensor ap-

proximately 5 duct diameters downstream from “pair of pants”

duct connection, allowing for adequate mixing of supply air.

Mount the sensor as follows:

1. Remove the cover of the sensor junction box.

2. Drill a

7

/

16

-in. hole at the selected location.

3. Install the sensor through the hole and secure using 2

no. 8 screws (provided). Do not overtighten.

4. Connect the sensor to the control box. Use an 18 or

20 AWG, 2 conductor, twisted pair cable. This cable is

suitable for distances of up to 500 feet.

Connect the field wires to the supply air sensor using wire

nuts or closed end style crimp connectors. Do not cut the

sensor leads. Use the full length of lead supplied on the sensor.

In the control box, remove the jacket from the cable. Route

the sensor wires over to the right hand side of the field terminal

block (TB2). Strip the insulation back about

1

/

4

-in. from each

conductor. Connect the two wires to terminals 101 and 102

(SAT) on the terminal board. Polarity is not a consideration.

See Table 11 for resistance vs. temperature values.

MANUFACTURER PART NUMBER

Alpha 2413 or 5463

American A22503

Belden 8772

Columbia 02525

Fig. 26 — Field Terminal Block

a50-7164tf

*Teflon is a registered trademark of E.I. du Pont de Nemours and

Company.

C O Y1 Y3 R G C O Y2 Y4

C O Y1 Y2 R G

PR2

PR1

PR1

PR2

FIELD-SUPPLIED THERMOSTAT

UNIT MODULE ‘A’ UNIT MODULE ‘B’

Remote Condenser Units Only

PR1

PR2

FC1-4 FC1-5

FC1-4 FC1-5

(#1)

(#2)

R

G

Fig. 25 — Typical Wiring 40 to 60 Ton Units (Two-Stage Cooling)

a50-7273ef

LEGEND

FC — Fan Contactor

PR — Pilot Relay