27

Modular Units

— For units with multiple main air-

conditioning sections, connect the high voltage compressor

power wiring to the line side of the high voltage terminal block

in the second section’s high voltage electrical box. This wiring

is located in the upper portion of the compressor compartment.

Connect the low voltage wiring, located in the compressor

compartment, between the two air conditioning sections using

the quick connects provided.

For the supply fan motor, connect the 3-phase high voltage

wiring, coiled behind the high voltage panel, to the line side of

the supply fan motor terminal block located in the fan compart-

ment. For VAV units, connect the 3-phase high voltage wiring

to the line side of VFD.

For units with multiple fans, connect the control power

wiring with the quick connects provided at the fan compart-

ment junction.

CONTROL WIRING (CV Only) — A standard commercial

thermostat controls constant volume units. These units turn

compressors on or off in response to zone temperature. The

50BV units provide 2 stages of cooling.

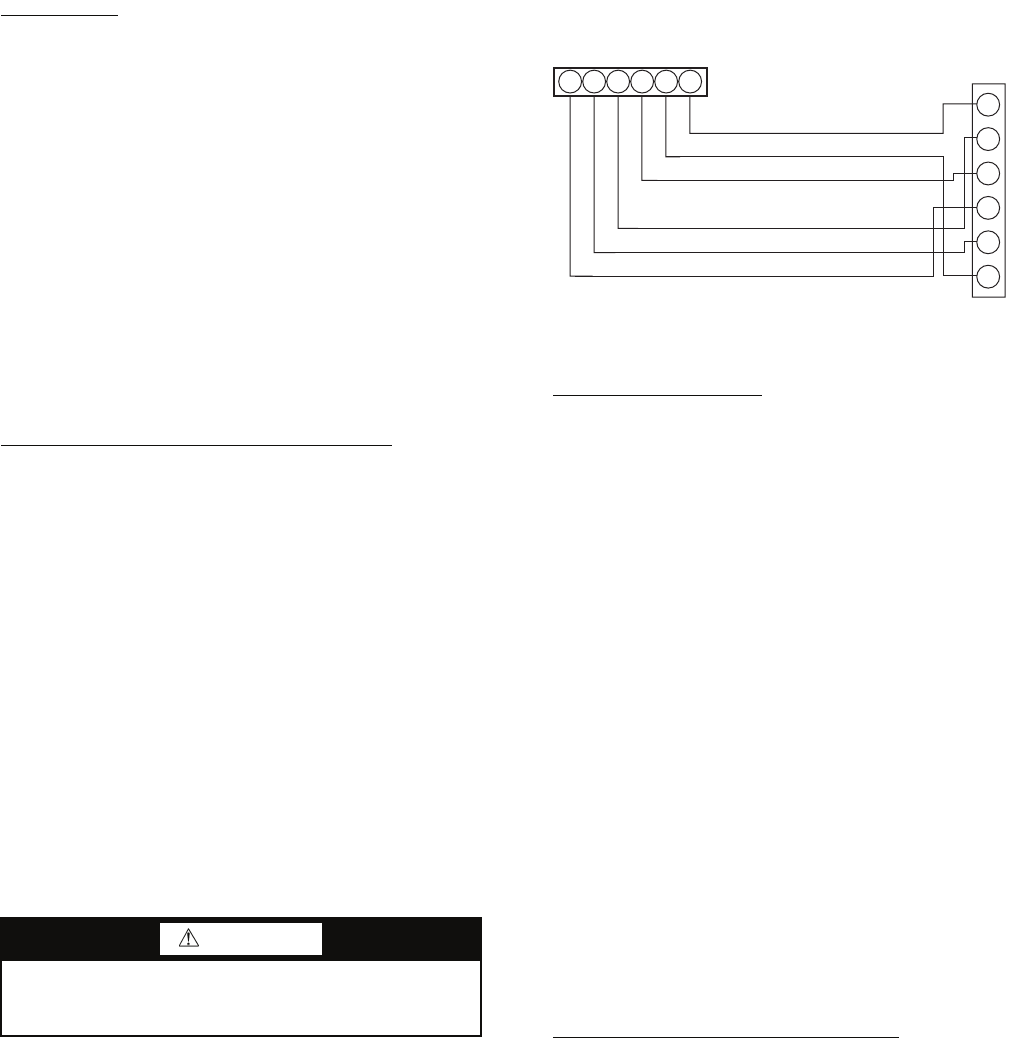

50BVC,E,Q020-034 and 50BVT,U,V034 Only

— These

models have 2 independent refrigerant circuits, each capable of

being staged independently. Thermostat wiring is connected to

the 6-position low voltage terminal block located in the unit

electrical box. The 50BV units have a 24-VAC control

transformer, which provides power to the control circuit and to

the thermostat. The thermostat connections and their functions

are as follows:

C Transformer 24-v ac Common

O Reversing Valve (heat pumps only)

Y1 1st Stage Compressor Contactor

Y2 2nd Stage Compressor Contactor

R Transformer 24-v ac Hot

G Indoor Fan Contactor

Select an appropriate commercial thermostat that has 2 stag-

es of cooling control. If the unit is a heat pump, make sure the

thermostat is capable of heat pump control. Any of the

Debonair® series commercial thermostats will meet the re-

quirements, and are available in a variety of attractive styles, in

programmable and non-programmable versions.

Install the thermostat in the space where the temperature is

being controlled, according to the instructions provided with

the thermostat.

To wire the thermostat:

1. Connect the ‘C’ terminal from the 50BV unit to the ‘C’

terminal on the thermostat.

2. Wire the ‘Y1’ and ‘Y2’ terminals from the 50BV unit

to the ‘Y1’ and ‘Y2’ terminals, respectively, at the

thermostat.

3. Make a connection between the ‘G’ terminal on the unit

and the ‘G’ terminal on the thermostat.

4. Attach a wire from the ‘R’ terminal at the unit to the ‘R’

terminal at the thermostat.

5. 50BVQ and 50BVV ONLY: If the unit is a heat pump,

connect a final wire from terminal ‘O’ on the heat pump

unit to the ‘W1/O/B’ terminal at the thermostat.

Configure the thermostat for heat pump operation using

the installation instructions provided with the thermostat.

Set the reversing valve polarity of the thermostat to ‘O’.

See Fig. 24 for typical thermostat wiring.

50BVT,U,V044-064 Only

— Units larger than 30 tons have 4

independent refrigerant circuits.

These units can be controlled using a standard commercial,

2-stage thermostat. In this case, the first stage of cooling will

turn on compressors 1 and 2, and the second stage will turn on

compressors 3 and 4. It is also possible to have 4 stages of cool-

ing, using a suitable field-supplied control method.

For 2-stage thermostat wiring, refer to Fig. 25. Jumpers

must be installed between the G and O terminals in Modules A

and B. A field-supplied, 24-v pilot relay should be used to en-

ergize Y2 on Module B whenever Y1 is energized on Module

A. Similarly, a field-supplied 24-v pilot relay should be in-

stalled to energize Y4 on Module B whenever Y3 on Module

A is energized (Y2 stage of thermostat calls for cooling).

Finally, verify that transformer phasing is consistent

between Modules A and B.

REMOTE CONDENSER FAN CONTACTOR WIR-

ING — For units up to 30 tons, one remote condenser is

required. Install a field-supplied 24-v pilot relay (Aux relay)

between Y1 and C. This will energize the FC contactor on the

remote condenser whenever there is a call for cooling.

For 40 to 60 ton units, 2 remote condensers are required. Be

sure to make piping connections so that compressors 1 and 2 are

connected to condenser 1, and compressors 3 and 4 are connect-

ed to condenser 2. Use an additional set of NO (normally open)

contacts on PR1 to energize FC1 on condenser 1, and a set of

NO contacts on PR2 to energize FC1 on condenser 2.

CONTROL WIRING (VAV Only) — The VAV units are de-

signed to operate either with a building management system or

stand alone (local control).

Carrier Comfort Network® Control Wiring

— The CC6400

Control Module connects to the Carrier Comfort Network

(CCN) bus in a daisy chain arrangement. Negative pins on

each component must be connected to respective negative pins

and likewise positive pins on each component must be

connected to respective positive pins. The controller signal pins

must be wired to the signal ground pins. Wiring connections

for CCN must be made at the 3-pin plug.

At any baud rate (9600, 19200, 38400 baud), the number of

controllers is limited to 239 devices maximum. Bus length may

not exceed 4000 ft, with no more than 60 total devices on any

1000-ft section. Optically isolated RS-485 repeaters are

required every 1000 ft.

NOTE: Carrier device default is 9600 baud.

The CCN communication bus wiring is field supplied and

field installed. It consists of shielded 3-conductor cable with

drain (ground) wire. The cable selected must be identical to the

CCN communication bus wire used for the entire network. See

Table 10 for cable recommendations.

WARNING

Before wiring the thermostat to the unit, make sure that

main power to the unit has been disconnected. Failure to

heed this warning could result in personal injury.

TYPICAL

UNIT

C

G

Y1

O

R

Y2

24 VAC COMMON

FAN RELAY

COMPRESSOR RELAY

HEAT PUMP

24 VAC RETURN

2nd STAGE COMPRESSOR RELAY

Y2

R

W1

Y1

G

C

THERMOSTAT

B

O

Fig. 24 — Typical Wiring 18 to 30 Ton Units

(Two-Stage Cooling Units)

a50-7272ef