59

TROUBLESHOOTING — Troubleshooting the Motormas-

ter

®

V control requires a combination of observing system op-

eration and VFD display information. The MMV should fol-

low the 4 to 20 mA signal from the ComfortLink™ controls.

The speed command from the ComfortLink controls can be

monitored in 2 ways:

1. Variables VH.PA, VH.PB in the "outputs" submenu of

ComfortLink - given as a percentage of 4 to 20 mA range.

2. P56 in Motormaster V shows 4-20 mA input in percent of

maximum input.

Refer to Table 24 for the variable definitions of each

controller.

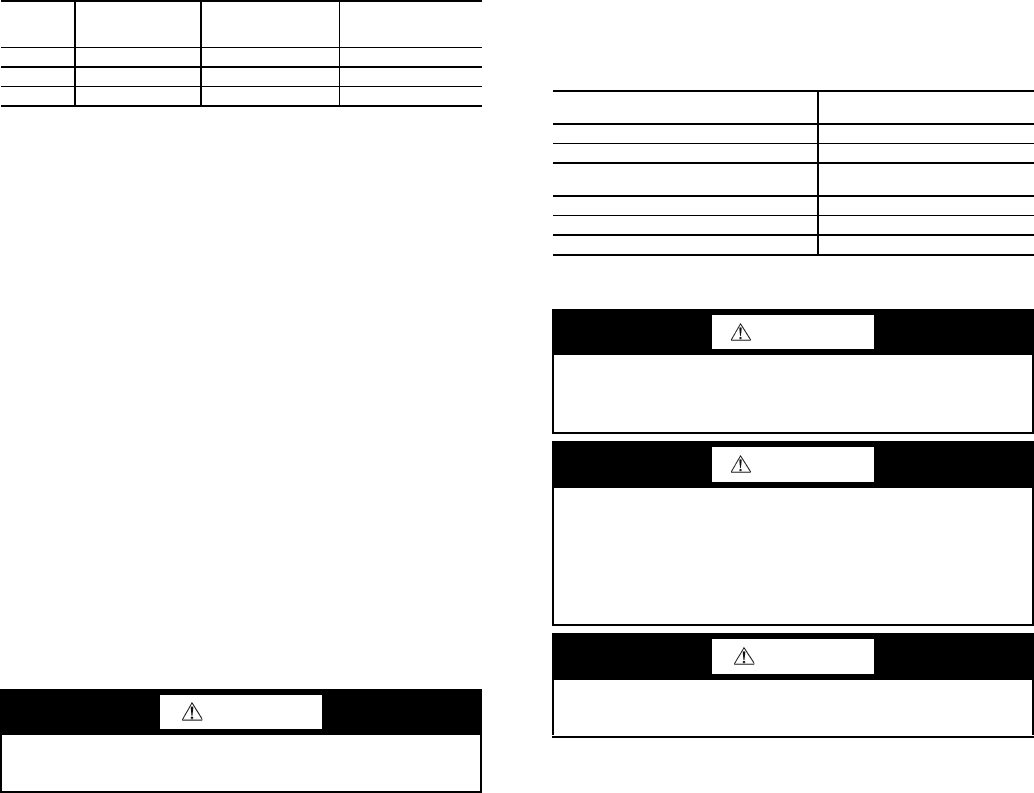

Table 24 — Controller Cross-Reference

The MMV also provides real time monitoring of key in-

puts and outputs. The collective group is displayed through pa-

rameters 50-56 and all values are read only.

• P50: FAULT HISTORY — Last 8 faults

• P51: SOFTWARE version

• P52: DC BUS VOLTAGE — in percent of nominal.

Usually rated input voltage x 1.4.

• P54: LOAD — in percent of drives rated output current

rating

• P55: VDC INPUT — in percent of maximum input: 50

will indicate full scale which is 5 v

• P56: 4-20 mA INPUT — in percent of maximum input:

20% = 4 mA, 100% = 20 mA

REPLACING DEFECTIVE MODULES — The Comfort-

Link

™

replacement modules are shown in Table 25. If the main

base board (MBB) has been replaced, verify that all configura-

tion data is correct. Follow the Configuration mode table and

verify that all items under sub-modes UNIT, OPT1 and OPT2

are correct. Any additional field-installed accessories or op-

tions (RSET, SLCT sub-modes) should also be verified as well

as any specific time and maintenance schedules.

Refer to the Start-Up Checklist for 38AP units (completed

at time of original start-up) found in the job folder. This infor-

mation is needed later in this procedure. If the checklist does

not exist, fill out the current information in the Configuration

mode on a new checklist. Tailor the various options and config-

urations as needed for this particular installation.

1. Check that all power to unit is off. Carefully disconnect

all wires from the defective module by unplugging its

connectors.

2. Remove the defective module by removing its mounting

screws with a Phillips screwdriver, and removing the

module from the control box. Save the screws for later

use.

3. Verify that the instance jumper (MBB) or address switch-

es (all other modules) exactly match the settings of the

defective module.

NOTE: Handle boards by mounting standoffs only to avoid

electrostatic discharge.

4. Package the defective module in the carton of the new

module for return to Carrier.

5. Mount the new module in the unit’s control box using a

Phillips screwdriver and the screws saved in Step 2.

6. Reinstall all module connectors. For accessory Naviga-

tor™ device replacement, make sure the plug is installed

at LVT in the LEN connector.

7. Carefully check all wiring connections before restoring

power.

8. Verify the ENABLE/OFF/REMOTE CONTACT switch

is in the OFF position.

9. Restore control power. Verify that all module red LEDs

blink in unison. Verify that all green LEDs are blinking

and that the scrolling marquee or Navigator display is

communicating correctly.

10. Verify all configuration information, settings, set points

and schedules. Return the ENABLE/OFF/REMOTE

CONTACT switch to its previous position.

Table 25 — Replacement Modules

Compressors

COMPRESSOR REPLACEMENT — To change out a

faulty compressor, refer to the compressor replacement proce-

dure included with the new compressor.

OIL CHARGE — Compressors are factory charged with

110 oz of POE oil. Refer to Oil Charge section page 47 for

proper oil and charge procedure.

MAINTENANCE

Recommended Maintenance Schedule —

The fol-

lowing are only recommended guidelines. Jobsite conditions

may dictate that maintenance schedule is performed more often

than recommended.

CONTROL

SIGNAL

VH.PA, VH.PB

(COMFORTLINK)

4-20 mA

INPUT (P56,

MOTORMASTER V)

VFD SPEED

(MOTORMASTER V)

4 mA 0% 20% 8 Hz

12 mA 50% 60% 26 Hz

20 mA 100% 100% 60 Hz

CAUTION

Electrical shock can cause personal injury. Disconnect all

electrical power before servicing.

MODULE

REPLACEMENT PART NO.

(with Software)

Main Base Board (MBB) 38AP501672

Scrolling Marquee Display HK50AA031

Energy Management

Module (EMM)

30GT515218

Navigator Display HK50AA033

Compressor Expansion Board HK50AA027

Auxiliary Board 32GB500442EE

WARNING

Do not supply power to unit with compressor cover

removed. Failure to follow this warning can cause a fire,

resulting in personal injury or death.

WARNING

Exercise extreme caution when reading compressor cur-

rents when high-voltage power is on. Correct any of the

problems described below before installing and running a

replacement compressor. Wear safety glasses and gloves

when handling refrigerants. Failure to follow this warning

can cause fire, resulting in personl injury or death.

CAUTION

Do not manually operate contactors. Serious damage to the

machine may result.