32

DEMAND LIMIT (CCN Loadshed Controlled) — To con-

figure Demand Limit for CCN Loadshed control, set the De-

mand Limit Select (Configuration RSET DMDC) to 3.

Then configure the Loadshed Group Number (Configura-

tion RSET SHNM), Loadshed Demand Delta (Configu-

ration RSET SHDL), and Maximum Loadshed Time

(Configuration RSET SHTM). See Table 13.

The Loadshed Group number is established by the CCN

system designer. The ComfortLink controls will respond to a

Redline command from the Loadshed control. When the Red-

line command is received, the current stage of capacity is set to

the maximum stages available. Should the loadshed control

send a Loadshed command, the ComfortLink controls will re-

duce the current stages by the value entered for Loadshed De-

mand delta. The maximum loadshed time is the maximum

length of time that a loadshed condition is allowed to exist. The

control will disable the Redline/Loadshed command if no Can-

cel command has been received within the configured maxi-

mum loadshed time limit.

Cooling Set Point (4 to 20 mA) — A field supplied

and generated, externally powered 4 to 20 mA signal can be

used to provide the leaving temperature set point. The energy

management module (EMM) must be used for cooling set

point control using a 4 to 20 mA signal. To use the 4 to 20 mA

set point, the unit type must be configured for control type VAV

set point (Configuration OPT2 C.TYP = 9). Once config-

ured, the control will translate the input linearly with 4 mA

equal to 40 F set point and 20 mA equal to 80 F set point. Con-

nect the signal to LVT strip terminal 10,8 (+,-). See Table 14

for instructions to enable the function. Figure 34 shows how

the 4 to 20 mA signal is linearly calculated.

Digital Scroll Option — The 38AP units have a

factory-installed option for a digital scroll compressor which

provides additional stages of unloading for the unit. The digital

compressor is always installed in the A1 compressor location.

When a digital compressor is installed, a digital unloader sole-

noid (DUS) is used on the digital compressor.

DIGITAL SCROLL OPERATION — A digital scroll oper-

ates in two stages - the "loaded state" when the solenoid valve

is normally closed and the "unloaded state" when the solenoid

valve is open. During the loaded state, the compressor operates

like a standard scroll and delivers full capacity and mass flow.

However, during the unloaded state, there is no capacity

and no mass flow through the compressor. The capacity of the

system is varied by varying the time the compressor operates

in an unloaded and loaded state during a 15-second period. If

the DUS is energized for 7.5 seconds, the compressor will be

operating at 50% capacity. If the DUS is energized for 11 sec-

onds, the compressor will be operating at approximately 25%

of its capacity. Capacity is the time averaged summation of

loaded and unloaded states, and its range is continuous from

10% to 100%. Regardless of capacity, the compressor always

rotates with constant speed. As the compressor transitions from

a loaded to unloaded state, the discharge and suction pressures

will fluctuate and the compressor sound will change.

The ComfortLink controller controls and integrates the op-

eration of the DUS into the compressor staging routine to

maintain temperature control. When a digital compressor is in-

stalled, an additional discharge gas thermistor (DTT) is in-

stalled along with the AUX board for control of the DUS.

DIGITAL COMPRESSOR CONFIGURATION — When a

digital compressor is installed, the configuration parameter

Configuration Unit A1.TY is configured to YES. There is

also a maximum unload time configuration, Configuration

Unit MAX.T, that is set to 7 seconds, which indicates the

maximum unloading for the digital compressor is 50%. This is

done to optimize efficiency of the system.

Table 14 — Configuration VAV 4 to 20 mA Set Point

MODE

(RED LED)

KEYPAD

ENTRY

SUB-MODE

KEYPAD

ENTRY

ITEM DISPLAY ITEM EXPANSION COMMENT

CONFIGURATION

DISP

UNIT

CCN

OPT1

OPT2 C.TYP 4 Unit Options 2 Controls

C.TYP 9 Machine Control Type

1 = VAV

3 = Tstat Multi

4 = Tstat 2 Stage

5 = SPT Multi

7 = PCT CAP

8 = Dual Stat

9 = VAV Set Point

ENTER

ENTER

ENTER

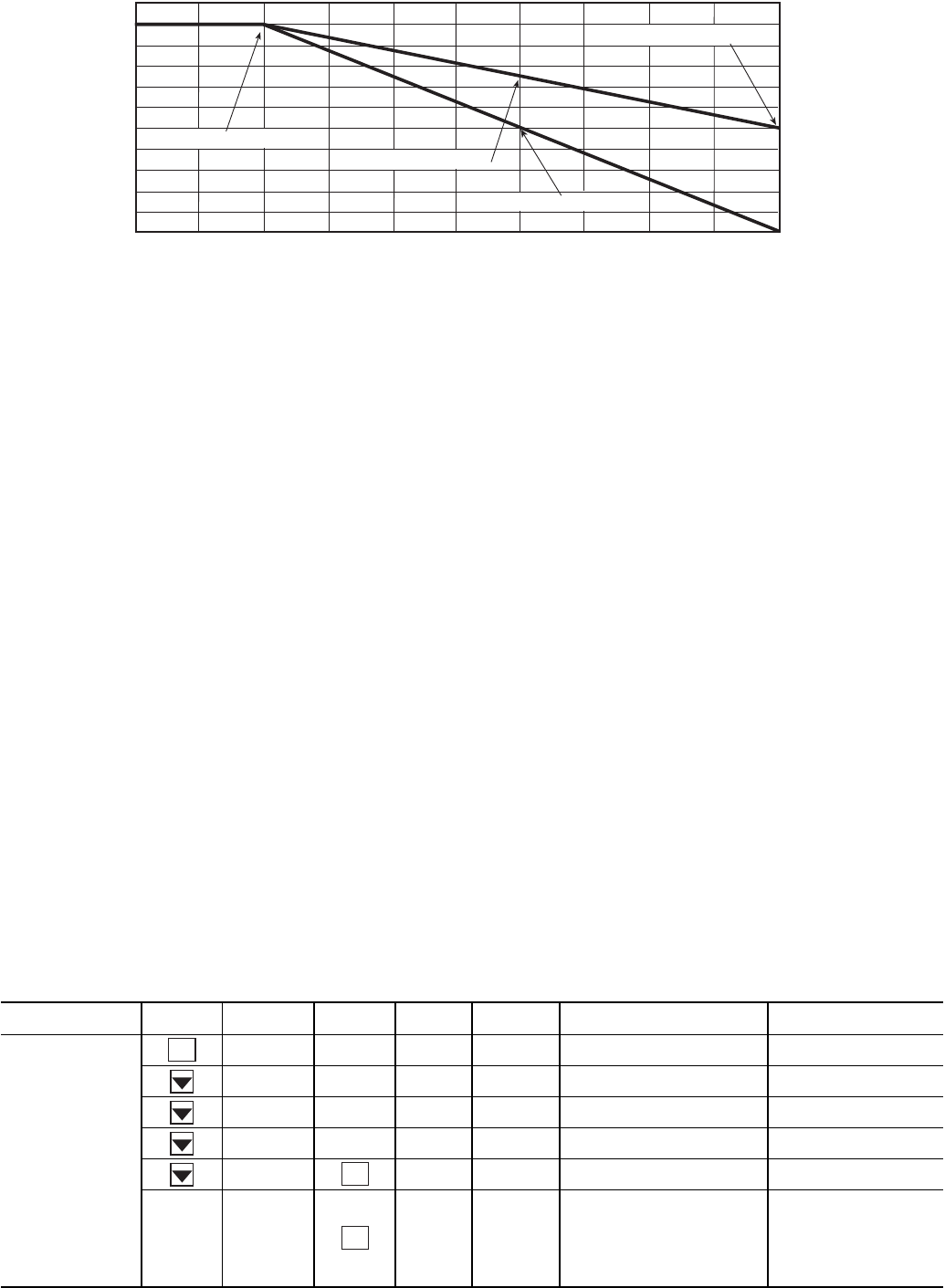

50% CAPACITY AT 20 mA

0

2

4

6

8

10

12

14

16 18

20

100

80

60

40

20

0

MAX.

ALLO

W

ABLE LO

AD (%

)

100% CAPACITY AT 4mA

75% CAPACITY AT 12 mA

50% CAPACITY AT 12 mA

DM20 = 50

DM20 = 0

DEMAND LIMIT SIGNAL – 4 - 20 mA INPUT

Fig. 33 — 4 to 20 mA Demand Limiting — Demand Limit Select (DMDC = 2)