19

Table 3 — Thermistor Designations

Table 4 — Switch Inputs

Compressor Expansion Module (CXB) — The

CXB is only used on unit sizes 070-100 to provide additional

inputs and outputs for fans and compressors when the unit has

more than 4 compressors.

AUX Board (AUX) — The AUX is used with the digital

scroll option and the low ambient head pressure option. It pro-

vides additional inputs and outputs for digital scroll control

along with analog outputs to control head pressure control fan

speeds.

Enable/Off/Remote Contact Switch — The Enable/

Off/Remote Contact switch is a 3-position switch used to

control the unit. When switched to the Enable position, the unit

is under its own control. Move the switch to the Off position to

shut the unit down. Move the switch to the Remote Contact po-

sition and a field-installed dry contact can be used to start the

unit. The contacts must be capable of handling a 24 vac, 50 mA

load. In the Enable and Remote Contact (dry contacts closed)

positions, the unit is allowed to operate and respond to the

scheduling configuration, CCN configuration and set point

data. See Fig. 21.

Emergency On/Off Switch — The Emergency On/Off

switch should only be used when it is required to shut the

unit off immediately. Power to the MBB, CXB, AUX, EMM,

and scrolling marquee display is interrupted when this switch is

off and all outputs from these modules will be turned off.

Board Addresses — The main base board (MBB) has a

3-position Instance jumper that must be set to ‘1.’ All other

boards have 4-position DIP switches. All switches are set to

‘On’ for all boards.

Control Module Communication

RED LED — Proper operation of the control boards can be

visually checked by looking at the red status LEDs

(light-emitting diodes). When operating correctly, the red status

LEDs should be blinking in unison at a rate of once every

2 seconds. If the red LEDs are not blinking in unison, verify

that correct power is being supplied to all modules. Be sure that

the main base board (MBB) is supplied with the current soft-

ware. If necessary, reload current software. If the problem still

persists, replace the MBB. A red LED that is lit continuously or

blinking at a rate of once per second or faster indicates that the

board should be replaced.

GREEN LED — The MBB has one green LED. The Local

Equipment Network (LEN) LED should always be blinking

whenever power is on. All other boards have a LEN LED

which should be blinking whenever power is on. Check LEN

connections for potential communication errors at the board J3

and/or J4 connectors. Communication between modules is

accomplished by a 3-wire sensor bus. These 3 wires run in

parallel from module to module. The J4 connector on the MBB

provides both power and communication directly to the

marquee display only.

YELLOW LED — The MBB has one yellow LED. The

Carrier Comfort Network (CCN) LED will blink during times

of network communication.

THERMISTOR INPUT PIN CONNECTION POINT

Return Air (Accessory) MBB J8-11,12; LVT 19,20

Supply Air (Accessory) MBB J8-12,13; LVT 11,19

Compressor Return Gas

Temperature A

MBB J8-1,2

Compressor Return Gas

Temperature B

MBB J8-3,4

Outdoor Air Temperature MBB J8-7,8

Discharge Temperature

(Digital Option Only)

AUX J6-1,2

Space Temperature (Accessory) MBB J8-5,6; LVT 21,22

SWITCH INPUT PIN CONNECTION POINT

Thermostat Y1 (Accessory) LVT 12,18

Thermostat Y2 (Accessory) LVT 15,18

Fan Status 1 (Accessory) LVT 16,18

Fan Status 2 (Accessory) LVT 17,18

Remote On/Off LVT 13,14

High Pressure Switch A MBB J6-4

High Pressure Switch B MBB J6-6

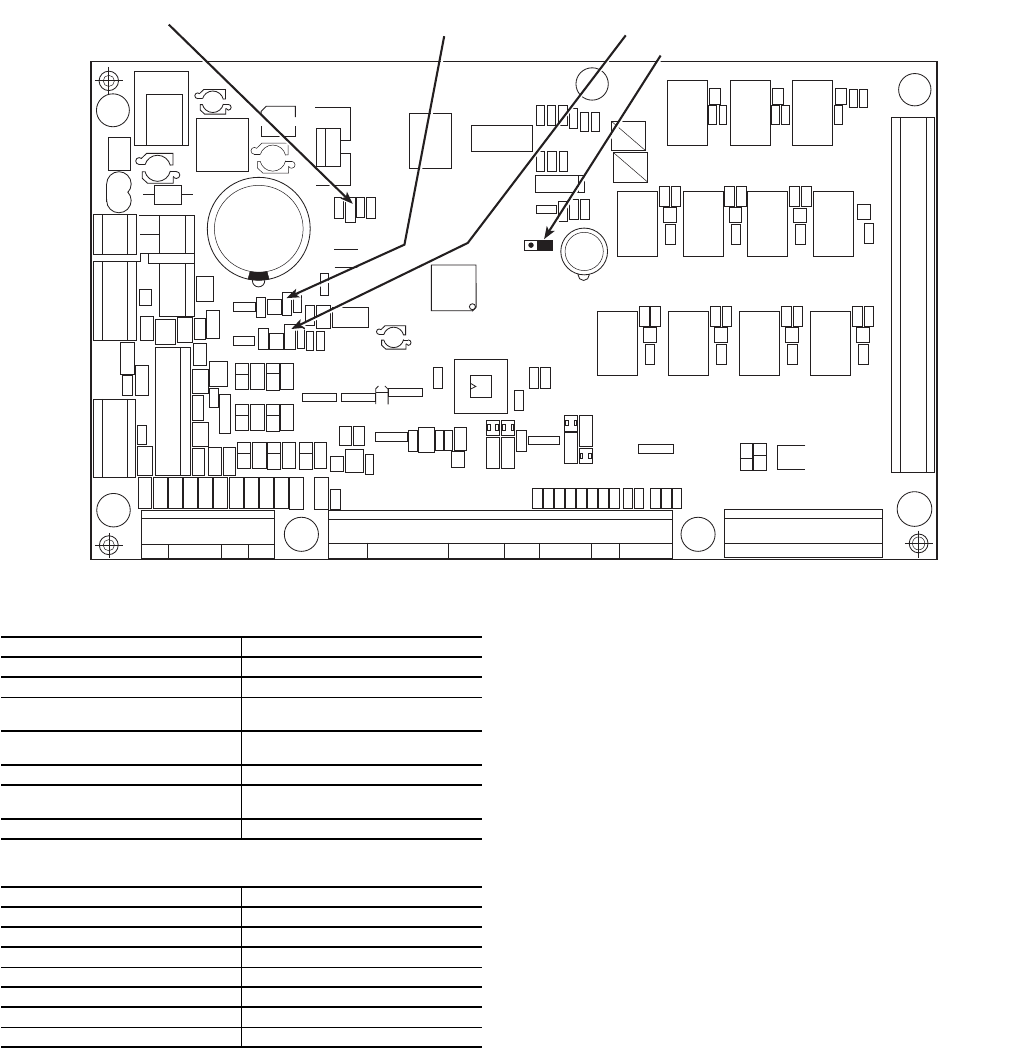

CEPL130346-01

STATUS

LEN

J1

J2

J4

J3

J5

J6

J7

J8

J9

J10

CCN

RED LED - STATUS GREEN LED -

LEN (LOCAL EQUIPMENT NETWORK)

YELLOW LED -

CCN (CARRIER COMFORT NETWORK)

INSTANCE JUMPER

K11

K10 K9

K8

K7

K6

K5

K4

K3 K2

K1

Fig. 20 — Main Base Board