Fig. 65 illustrates an easy method of obtaining thermostat amp

draw measurements. The amp reading should be taken after blower

motor has started and furnace is operating in low-heat.

1. To operate furnace in low-heat, turn setup switch SW1-2 to

ON position (See Fig. 32) and connect ammeter leads

across thermostat subbase R-W.

2. See thermostat manufacturer’s instructions for adjusting the

heat anticipator and for varying heating cycle length.

NOTE: When using an electronic thermostat, set cycle rate for 3

cycles per hr.

3. Return setup switch SW1-2 to OFF position and replace

thermostat on subbase.

CHECK SAFETY CONTROLS

This section covers the safety controls that must be checked before

the installation is complete. The flame sensor, gas valve, and

pressure switches were all checked in the Start-up procedure

section as part of normal operation.

I. CHECK PRIMARY LIMIT CONTROL

This control shuts off the gas control system and energizes the

air-circulating blower motor if furnace overheats.

1. The recommended method of checking this limit control is

to gradually block off return air after furnace has been

operating for a period of at least 5 minutes.

2. As soon as limit control has shut off burners, a 33 status

code will appear on furnace control.

3. The return-air opening should be quickly unblocked to

permit normal air circulation.

By using this method to check the limit control, it can be

established that the limit is functioning properly and the furnace

will operate safely if there is a restricted return-air duct or motor

failure. If the limit control does not function during this test, the

cause must be determined and corrected.

II. CHECK PRESSURE SWITCHES

This control proves operation of the draft inducer. Check switch

operation as follows:

1. Turn off 115-v power to furnace.

2. Remove control access door and disconnect inducer motor

12-pin wire harness at inducer motor.

3. Turn on 115-v power to furnace.

4. Set thermostat to ″call-for-heat.″ When pressure switches

are functioning properly, status code 42 will flash on

furnace control approximately 20 sec after thermostat

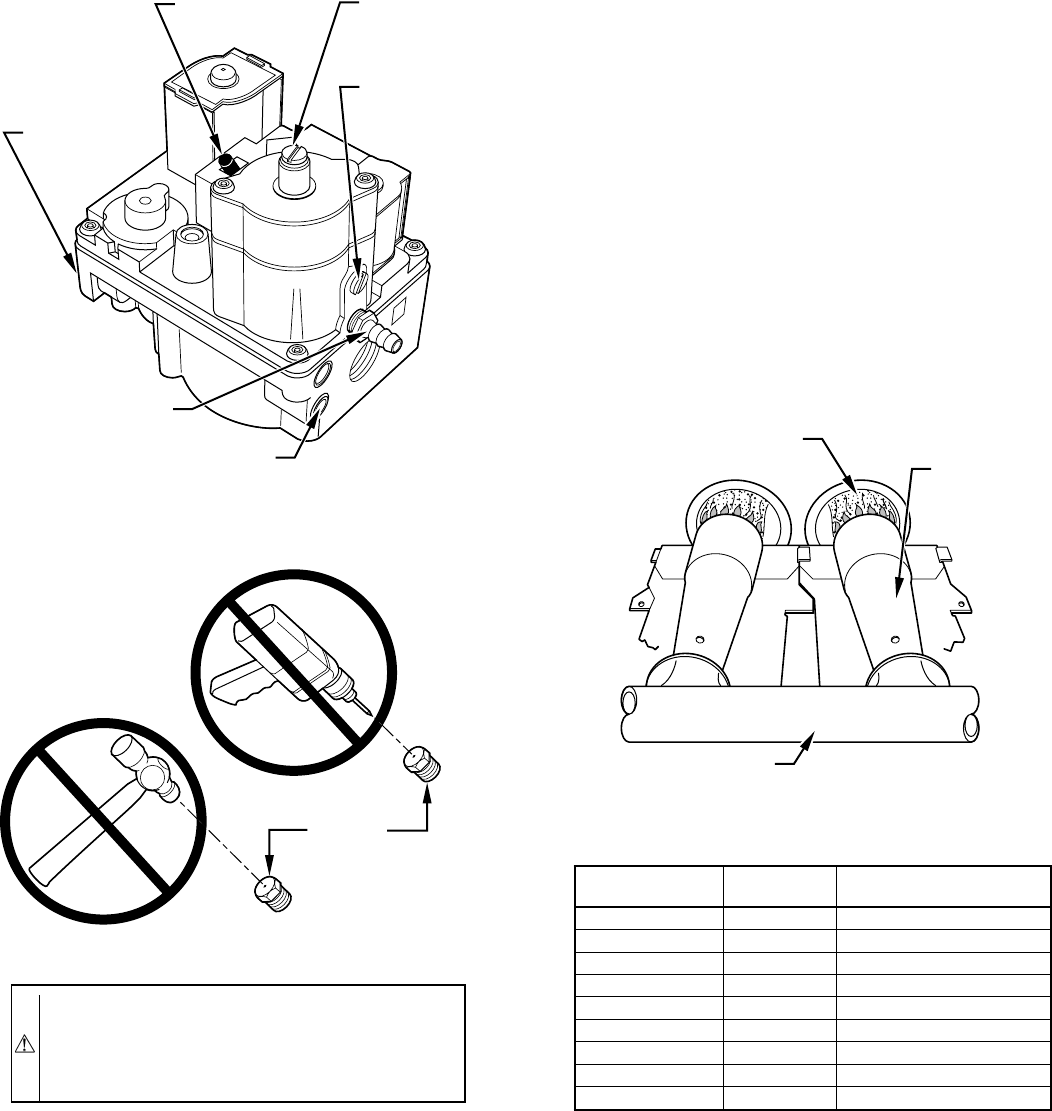

Fig. 62—Redundant Automatic Gas Valve

A97386

ON/OFF

SWITCH

INLET

PRESSURE

TAP

ON

O

F

F

BURNER

ENCLOSURE

REFERENCE

PRESSURE TAP

MANIFOLD

PRESSURE

TAP

LOW-FIRE

ADJUSTMENT

ALLEN SCREW

(UNDER CAP)

HIGH-FIRE

ADJUSTMENT

ALLEN SCREW

(UNDER CAP)

CAUTION: DO NOT redrill orifices. Improper drilling

(burrs, out-of-round holes, etc.) can cause excessive

burner noise and misdirection of burner flames. This can

result in flame impingement of burners and heat exchang-

ers, causing failures. (See Fig. 63.)

A93059

Fig. 63—Burner Orifice

BURNER

ORIFICE

Fig. 64—Burner Flame

A89020

BURNER FLAME

BURNER

MANIFOLD

TABLE 12—ALTITUDE DERATE MULTIPLIER FOR U.S.A.

ALTITUDE

(FT)

%OF

DERATE

DERATE MULTIPLIER

FACTOR

0—2000 0 1.00

2001—3000 4—6 0.95

3001—4000 6—8 0.93

4001—5000 8—10 0.91

5001—6000 10—12 0.89

6001—7000 12—14 0.87

7001—8000 14—16 0.85

8001—9000 16—18 0.83

9001—10,000 18—20 0.81

* Derate multiplier factors are based on midpoint altitudes for altitude ranges.

—45—

→