g. Jumper R and W/W1 and W2 thermostat connections on

furnace control. (See Fig. 32.) This keeps furnace locked

in high-heat operation.

h. Turn high-heat adjusting screw (3/32 hex Allen wrench)

counterclockwise (out) to decrease input rate or clock-

wise (in) to increase rate.

NOTE: DO NOT set high-heat manifold pressure less than 3.2-in.

wc or more than 3.8-in. wc for natural gas. If manifold pressure is

outside this range, change main burner orifices to obtain manifold

pressures in this range.

i. When correct input is obtained, replace caps that conceal

gas valve regulator adjustment screws. Main burner

flame should be clear blue, almost transparent. (See Fig.

64.)

j. Remove jumpers R-to-W/W1 and R-to-W2.

3. Verify natural gas input rate by clocking gas meter.

NOTE: Be sure all pressure tubing, combustion-air and vent

pipes, and burner enclosure front are in place when checking input

by clocking gas meter.

a. Calculate high-altitude adjustment (if required).

UNITED STATES

At altitudes above 2000 ft, this furnace has been ap-

proved for a 2 percent derate for each 1000 ft above sea

level. See Table 12 for derate multiplier factor and

example.

EXAMPLE: 100,000 BTUH HIGH-HEAT INPUT FURNACE IN-

STALLED AT 4300 FT.

Furnace Input Rate

at Sea Level

X

Derate

Multiplier

Factor

=

Furnace Input Rate

at Installation

Altitude

100,000 X 0.91 = 91,000

CANADA

At installation altitudes from 2000 to 4500 ft, this

furnace must be derated 5 percent by an authorized Gas

Conversion Station or Dealer. To determine correct input

rate for altitude, see example above and use 0.95 as

derate multiplier factor.

b. Reinstall burner box cover.

NOTE: Clocking gas input rate MUST always be performed with

the burner box cover INSTALLED.

c. Check that gas valve adjustment caps are in place for

proper input to be clocked.

d. Obtain average heat value (at altitude) from local gas

supplier.

NOTE: Be sure heating value of gas used for calculations is

correct for your altitude. Consult local gas utility for altitude

adjustment of gas heating value.

e. Check and verify orifice size in furnace. NEVER AS-

SUME THE ORIFICE SIZE. ALWAYS CHECK AND

VERIFY.

f. Turn off all other gas appliances and pilots.

g. Turn setup switch SW1-2 to ON position. (See Fig. 32.)

This keeps furnace locked in low-heat operation.

h. Jumper R-to-W/W1

i. Let furnace run for 3 minutes in low-heat operation.

j. Measure time (in sec) for gas meter to complete 1

revolution. Note reading.

k. Refer to Table 13 for cubic ft of gas per hr.

l. Multiply gas rate cu ft/hr by heating value (Btu/cu ft).

m. Turn setup switch SW1-2 to OFF position and jumper R

and W/W1 and W2 thermostat connections. (See Fig.

32.) This keeps furnace locked in high-heat operation.

Repeat items i through l for high-heat operation.Fig. 59—Example of Setup Switch in OFF Position

A95198

1

OFF

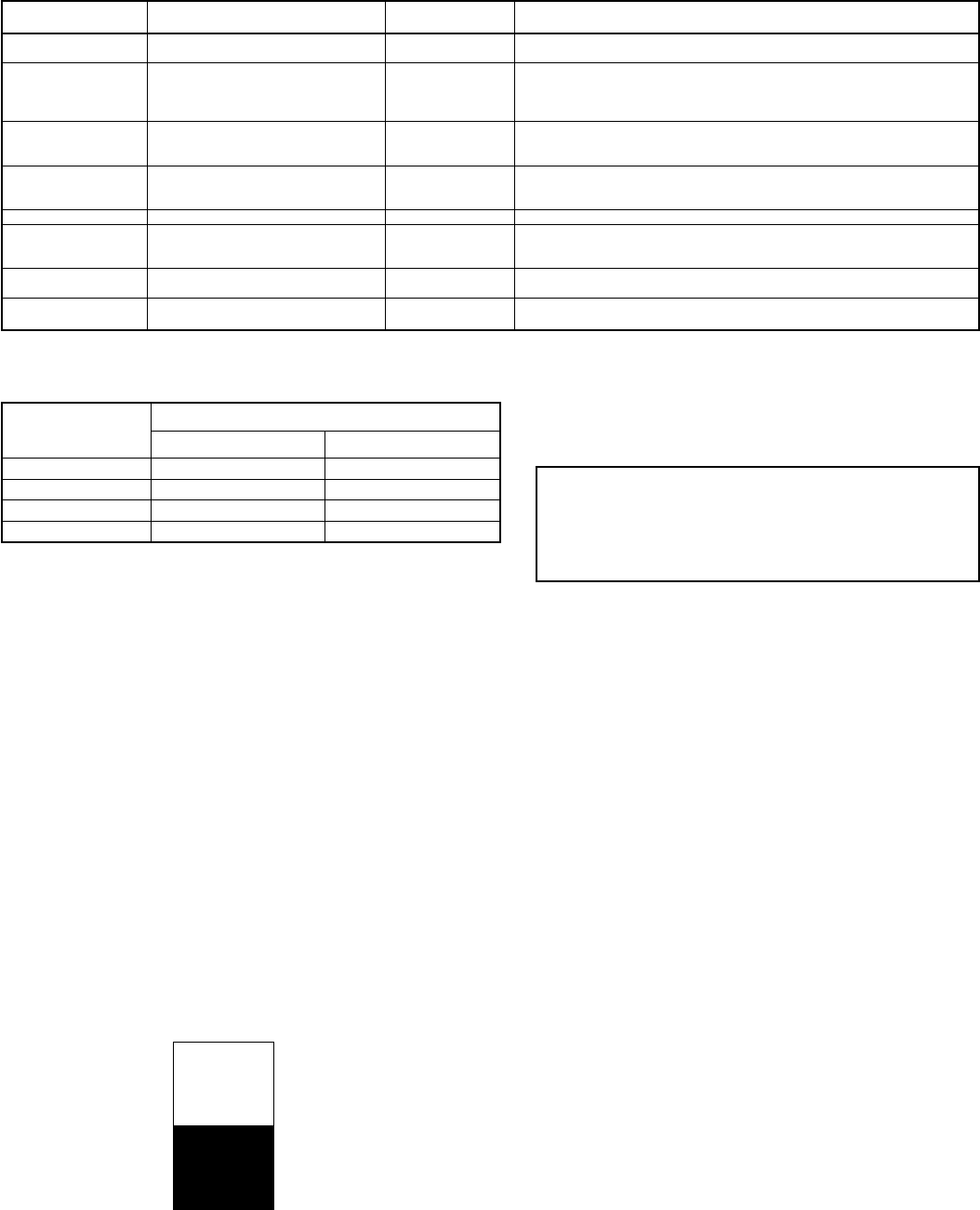

TABLE 9—FURNACE SETUP SWITCH DESCRIPTION

SETUP

SWITCH NO.

SWITCH

NAME

NORMAL

POSITION

DESCRIPTION

OF USE

SW1-1 Status Code Recovery OFF

Turn ON to retrieve up to 7 stored status codes for troubleshooting

assistance when R thermostat lead is disconnected.

SW1-2 Adaptive Heat Mode OFF

Allows 2-stage operation with a single stage thermostat.

Turn ON when using 2 stage thermostat to allow Low Heat opera-

tion when R to W/W1 closes and High Heat operation when R to

W/W1 and W2 close.

SW1-3

Low Heat

Rise Adjust

OFF

Turn ON to increase Low Heat airflow by 18 percent. This compen-

sates for increased return air temperature caused with bypass hu-

midifier.

SW1-4 Comfort/Efficiency Adjustment ON

Turn ON to decrease Low Heat airflow by 7 percent and High Heat

airflow 8 percent for maximum comfort. On 040 unit will decrease

Low-Heat Airflow 11 percent and High-Heat Airflow 10 percent.

SW1-5 CFM per ton adjust OFF Turn ON for 400 CFM per ton. Turn OFF for 350 CFM per ton.

SW1-6 Component Self-Test OFF

Turn ON to initiate Component Self-Test for troubleshooting assis-

tance when R thermostat lead is disconnected.

Turn OFF when Self-Test is completed.

SW1-7 Blower OFF delay ON or OFF

Control blower Off Delay time. Used in conjunction with SW1-8. See

Table 10.

SW1-8 Blower OFF delay ON or OFF

Control blower Off Delay time. Used in conjunction with SW1-7. See

Table 10.

TABLE 10—BLOWER OFF DELAY SETUP SWITCH

POSITION

DESIRED HEATING

MODE BLOWER

OFF DELAY (SEC)

SETUP SWITCH (SW1-7 AND SW1-8) POSITION

SW1-7 SW1-8

90 OFF OFF

120 ON OFF

150 OFF ON

180 ON ON

—41—

→