SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified person-

nel should install, repair, or service heating equipment. Untrained

personnel can perform basic maintenance functions such as clean-

ing and replacing air filters. All other operations must be per-

formed by trained service personnel. When working on heating

equipment, observe precautions in literature, on tags, and on labels

attached to or shipped with unit and other safety precautions that

may apply.

Follow all safety codes, including the National Fuel Gas Code

(NFGC) NFPA 54/ANSI Z223.1-1996, and the Installation Stan-

dards, Warm Air Heating and Air Conditioning Systems (NFPA

90B) ANSI/NFPA 90B. In Canada, refer to the current edition of

the CAN/CGA-B149.1 and .2-M95 National Standard of Canada,

Natural Gas and Propane Installation Codes (NSCNGPIC). Wear

safety glasses and work gloves. Have a fire extinguisher available

during start-up and adjustment procedures and service calls.

Recognize safety information. This is the safety-alert symbol

.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability,

or operation.

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

CAUTION: Electrostatic discharge can affect electronic

components. Take precautions during furnace installation

and servicing to protect the furnace electronic control.

Precautions will prevent electrostatic discharges from

personnel and hand tools which are held during the

procedure. These precautions will help to avoid exposing

the control to electrostatic discharge by putting the

furnace, the control, and the person at the same electro-

static potential.

1. Disconnect all power to the furnace. DO NOT TOUCH

THE CONTROL OR ANY WIRE CONNECTED TO THE

CONTROL PRIOR TO DISCHARGING YOUR BODY’S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch a clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools held in

a person’s hand during grounding will be satisfactorily

discharged.

3. After touching the chassis you may proceed to service the

control or connecting wires as long as you do nothing that

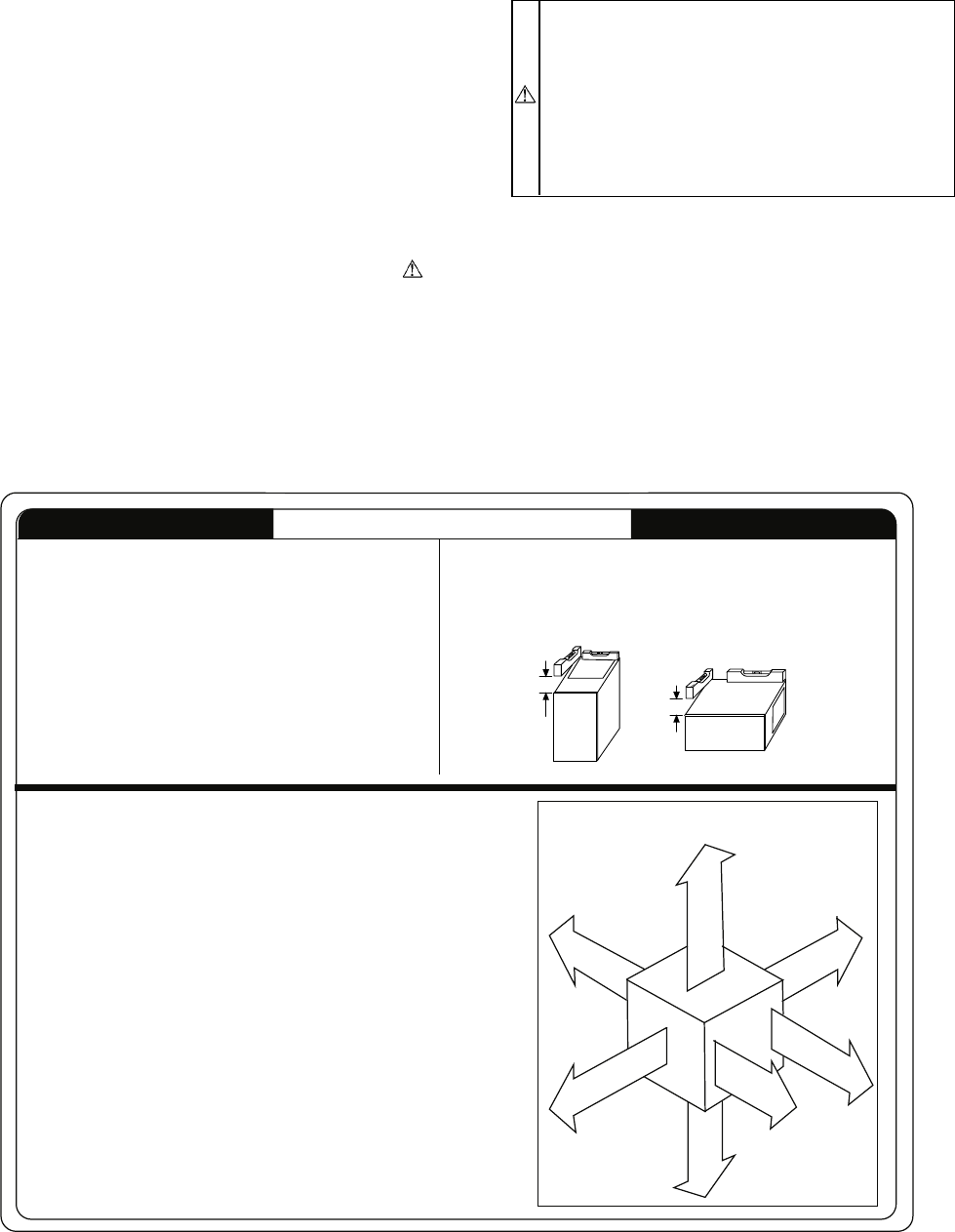

→ Fig. 3—Clearances to Combustibles

A99101

This forced air furnace is equipped for use with natural gas at altitudes 0 -

10,000 ft (0 - 3,050m), except 140 size Furnaces are only approved for

altitudes 0 - 7,000ft. (0 - 2,135m).

An accessory kit, supplied by the manufacturer, shall be used to convert to

propane gas use or may be required for some natural gas applications.

This furnace is for indoor installation in a building constructed on site. This

furnace may be installed in a manufactured (mobile) home when stated on

rating plate and using factory authorized kit.

This furnace may be installed on combustible flooring in alcove or closet at

minimum clearance from combustible material.

This appliance requires a special venting system. Refer to the installation

instructions for parts list and method of installation. This furnace is for use with

schedule-40 PVC, PVC-DWV, or ABS-DWV pipe, and must not be vented in

common with other gas-fired appliances. Construction through which vent/air

intake pipes may be installed is maximum 24 inches (600 mm), minimum 3/4

inches (19 mm) thickness (including roofing materials).

MINIMUM INCHES CLEARANCE TO

COMBUSTIBLE CONSTRUCTION

*

Minimum front clearance for service 30 inches (762mm).

140 size furnaces require 1 inch back clearance to combustible materials.

For installation on combustible floors only when installed on special base

No. KGASB0201ALL, Coil Assembly, Part No. CD5 or CK5, or Coil Casing,

Part No. KCAKC.

Clearance shown is for air inlet and air outlet end.

Line contact is permissible only between lines formed by intersections of

top and two sides of furnace jacket, and building joists, studs, or framing.

120 and 140 size Furnaces require 1 inch bottom clearance to combustible

materials.

Ø

§

Clearance in inches .

Vent clearance to

combustibles 0".

This furnace is approved for UPFLOW, DOWNFLOW and

HORIZONTAL installations.

*

BOTTOM

0"

Ø

3"

0"

§

0"

TOP/PLENUM

1"

0"

§

30

MIN

ALL POSITIONS:

DOWNFLOW POSITIONS:

HORIZONTAL POSITIONS:

S

I

D

E

F

R

O

N

T

B

C

K

A

S

E

R

V

I

E

C

F

R

O

N

T

S

I

D

E

U

F

R

N

A

C

E

Clearance arrows

do not change with

furnace orientation.

†

†

†

†

HORIZONTAL

UPFLOW OR

DOWNFLOW

1/2" MAX

FRONT

FRONT

1/2" MAX

TO

LEVEL (0")

LEVEL (0")

TO

†

†

INSTALLATION

Furnace must be installed level, or pitched forward within 1/2 inch of

level for proper drainage. Failure will result in equipment or property

damage. See Installation Manual for IMPORTANT unit support details

on horizontal applications.

324999-201 REV. A

(LIT. TOP)

FRONT

FRONT

—3—