NOTE: Do not attach combustion-air intake pipe permanently to

combustion-air intake housing since it may be necessary to remove

pipe for service of ignitor or flame sensor.

The combustion-air intake plug fitting must be installed in

unused combustion-air intake housing. This fitting must be

attached by using RTV sealant, or by drilling a 1/8-in. hole

in fitting, using hole in intake housing as a guide. Install a

field-supplied No. 6 or No. 8 sheet metal screw.

NOTE: DO NOT OVERTIGHTEN SCREW. Breakage to intake

housing or fitting may cause air leakage to occur.

A plugged drain connection has been provided on this

fitting for use when moisture is found in combustion-air

intake pipe and combustion box. If use of this drain

connection is desired, drill out fitting’s tap plug with a

3/16-in. drill and connect a field-supplied 3/8-in. tube. This

tube should be routed to open condensate drain for furnace

and A/C (if used), and should be trapped. (See Fig. 30.)

C. Vent Pipe

NOTE: Furnace vent pipe connections are sized for 2-in. pipe.

Any vent pipe size change should be made outside furnace casing

in vertical pipe. (See Fig. 31.) This allows proper drainage of vent

condensate.

Determine vent pipe diameter and maximum pipe lengths using

Table 4.

Furnace vent pipe connection must be attached as shown in Fig.

28. Inducer housing alternate vent cap may need to be relocated in

some applications.

NOTE: Starting at furnace, slope vent pipe a minimum of 1/4 in.

per linear ft upward to termination(s) with no sags between

hangers.

CAUTION: When vent pipe is exposed to temperatures

below freezing, such as when it passes through an

unheated space or when a chimney is used as a raceway,

pipe must be insulated as described in Table 5 with

Armaflex-type insulation.

WARNING: Vent pipes must be airtight and watertight.

Failure to follow this warning could result in property

damage, personal injury, or death.

NOTE: The minimum vent pipe length for these furnaces is 5 ft.

Short pipe lengths (5-8 ft) may discharge water droplets. These

droplets may be undesirable, and a 12-in. minimum offset pipe

section is recommended to reduce excessive droplets from exiting

vent pipe outlet. (See Fig. 32.)

NOTE: Do not count elbows or pipe sections in terminations or

within furnace. See shaded areas in Fig. 34.

EXAMPLE:

An 036080 size furnace located in Indianapolis, eleva-

tion 650 ft above sea level, could be installed in an

application requiring 3 elbows and 32 ft of vent pipe.

Table 4 indicates this application would allow a 2-in.

diameter vent pipe. At 0-2000 ft elevation, 2-in. pipe is

good for up to 35 ft with 3 elbows. If same installation

were in Albuquerque, elevation 5250 ft above sea

level, installation would require 2-1/2 in. vent pipe. At

5001- to 6000-ft elevation, 2-in. pipe is allowed for up

to 23 ft with 3 elbows, but 2-1/2 in. pipe can be used for

up to 70 ft with 3 elbows.

Install vent pipe as follows:

1. Determine location of vent pipe connection to inducer

housing as shown in Fig. 28 for application.

2. Reposition elastomeric (rubber) inducer housing outlet cap

and clamp to appropriate unused inducer housing connec-

tion. Tighten clamp.

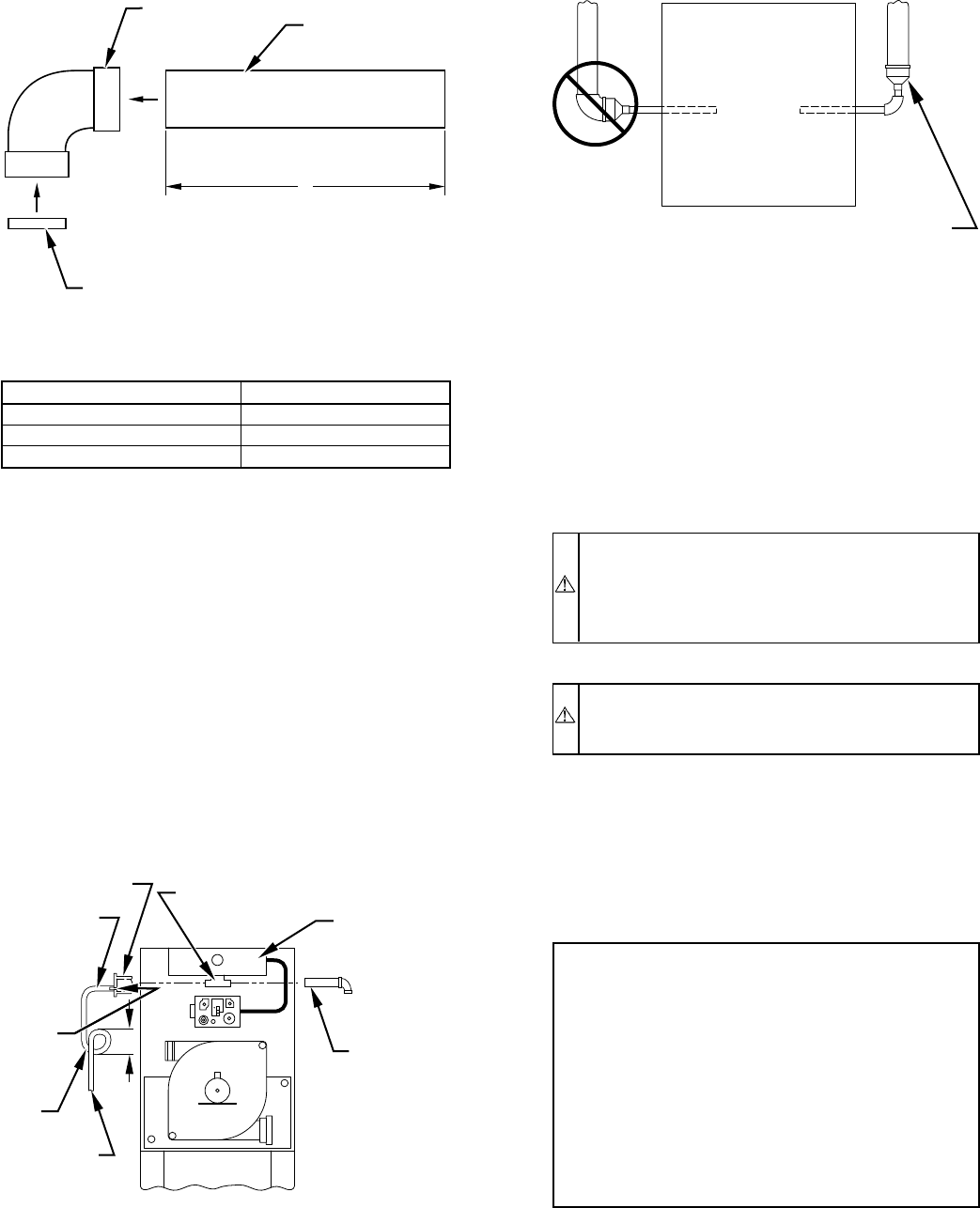

Fig. 29—Combustion-Air Inlet Pipe Assembly

LENGTH OF STRAIGHT PIPE PORTION OF

COMBUSTION-AIR INLET PIPE ASSEMBLY (IN.)

CASING WIDTH A

17-1/2 8-1/2 ± 1/2

21 10-1/2 ± 1/2

24-1/2 12 ± 1/2

A96211

FIELD-SUPPLIED

2-IN. DIAMETER

PVC PIPE

FIELD-SUPPLIED

2-IN. DIAMETER

PVC 90° ELBOW

COMBUSTION-AIR DISC

(FACTORY-SUPPLIED IN

LOOSE PARTS BAG)

A

Fig. 30—Intake Housing Plug Fitting Drain

A96190

COMBUSTION–

AIR PIPE

BURNER

BOX

COMBUSTION–AIR

INTAKE HOUSING

3/8

″ ID TUBE

TRAP

TO OPEN

DRAIN

3/16

″

DRILL

HOUSING

PLUG

4″

MIN

Fig. 31—Vent Pipe Diameter Transition Location and

Elbow Configuration

A93034

FURNACE

PIPE DIAMETER

TRANSITION IN

VERTICAL SECTION

NOT IN

HORIZONTAL

SECTION

—24—

→