II. 24-V WIRING

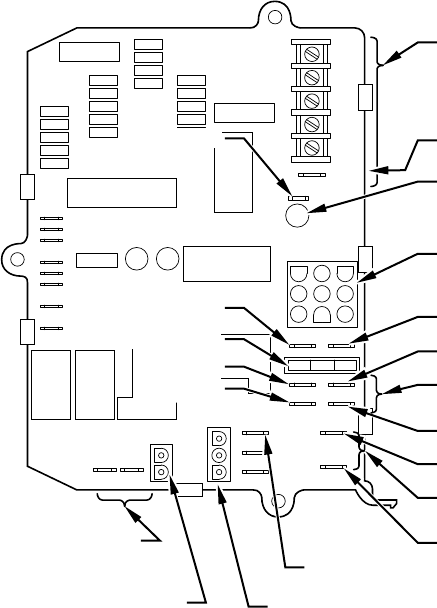

Make field 24-v thermostat connections at 24-v terminal block on

control center. For proper cooling operation, Y wire from thermo-

stat MUST be connected to Y terminal on control center, as shown

in Fig. 24. The 24-v terminal board is marked for easy connection

of field wiring. (See Fig. 26.) The 24-v circuit contains a 3-amp,

automotive-type fuse located on control center. (See Fig. 27.) Any

electrical shorts of 24-v wiring during installation, service, or

maintenance may cause fuse to blow. If fuse replacement is

required, use only a fuse of identical size (3 amp).

NOTE: Use AWG No. 18 color-coded copper thermostat wire for

lengths up to 100 ft. For wire lengths over 100 ft, use AWG No.

16 wire.

III. ACCESSORIES

1. Electronic Air Cleaner (EAC)

Two quick-connect terminals marked EAC-1 and EAC-2

are provided for EAC connection. (See Fig. 27.) These

terminals are energized with 115v (1.5-amp maximum)

during blower motor operation.

2. Humidifier (HUM)

A quick-connect terminal (HUM) and screw terminal (C

OM)

are provided for 24-v humidifier connection. (See Fig. 26.)

HUM terminal is energized with 24v (0.5-amp maximum)

after inducer motor prepurge period.

NOTE: A field-supplied, 115-v controlled relay connected to

EAC terminals may be added if humidifier operation is desired

during blower operation.

VENTING

The 345MAV Furnaces require a dedicated, (one 345MAV fur-

nace only) sealed vent system. All air for combustion is taken from

the area adjacent to furnace, and all flue products are discharged to

outside atmosphere.

I. REMOVAL OF EXISTING FURNACES FROM

COMMON VENT SYSTEMS

If furnace being replaced was connected to a common vent system

with other appliances, the following steps shall be followed with

each appliance connected to the venting system placed in opera-

tion, while any other appliances connected to the venting system

are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch as required in the National Fuel Gas Code, ANSI

Z223.1 or the CAN/CGA B149 Installation Codes and these

instructions. Determine that there is no blockage or restric-

tion, leakage, corrosion, and other deficiencies which could

cause an unsafe condition.

3. In so far as is practical, close all building doors and

windows and all doors between the space in which the

appliance(s) connected to the venting system are located

and other spaces of the building. Turn on clothes dryers and

any appliance not connected to the venting system. Turn on

any exhaust fans, such as range hoods and bathroom

exhausts, so they shall operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so appliance shall

operate continuously.

5. Test for draft hood equipped appliance spillage at the draft

hood relief opening after 5 minutes of main burner opera-

tion. Use the flame of a match or candle.

6. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace damp-

ers, and any other gas-burning appliance to their previous

conditions of use.

Fig. 27—Control Center

A95086

C

OM

24V

HUM

GRYW

3-AMP FUSE

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP MAX)

LED OPERATION &

DIAGNOSTIC LIGHT

HARNESS CONNECTOR

24-V TRANSFORMER SEC-2

SPARE-1

SPARE-2

EAC-1

EAC-ELECTRONIC AIR CLEANER

TERMINALS (115-VAC 1.5 AMP MAX)

EAC-2

115-VAC (L2) NEUTRAL

CONNECTION

24-V THERMOSTAT

TERMINALS

BLOWER SPEED

SELECTION TERMINALS

INDUCER MOTOR

CONNECTOR

115-VAC (L1)

POWER SUPPLY

HOT SURFACE

IGNITOR CONNECTOR

HEAT

COOL

SEC-1

TEST/TWIN

—22—