Pro Sweep

Page 4 -- 10

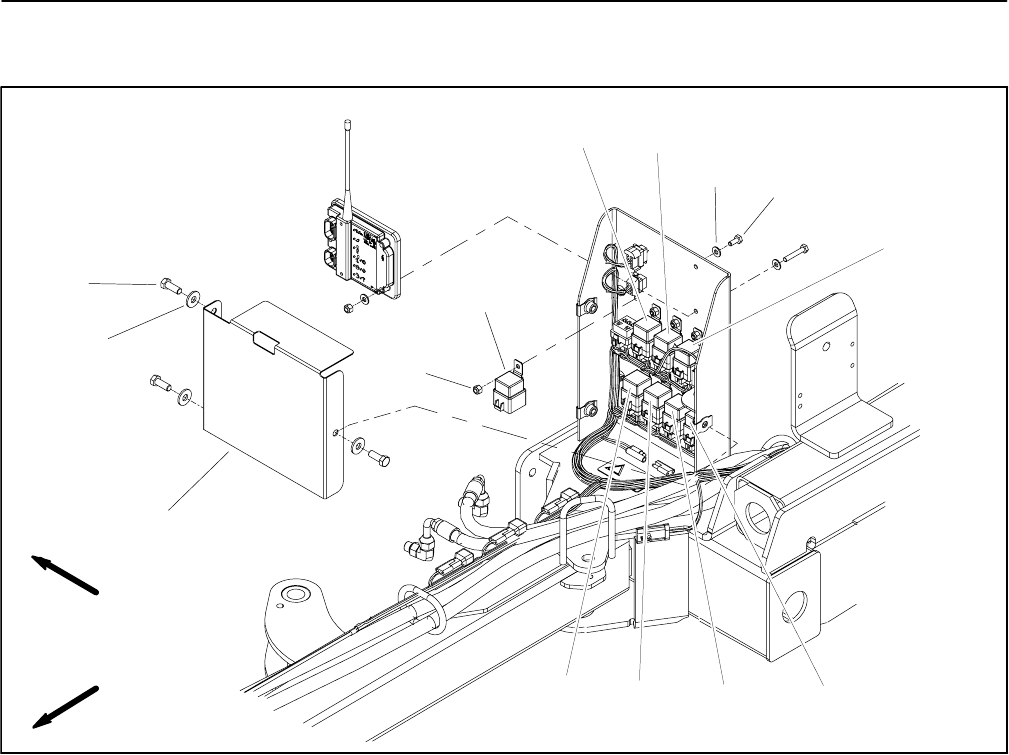

Electrical System

Relays

1. Cover

2. Flat washer (3 used)

3. Cap screw (3 used)

4. Cap screw (8 used)

5. Flat washer (8 used)

6. Lock nut (8 used)

7. Hopper Height Select relay

8. Logic Inverter relay

9. Broom relay

10. Up Function Select relay

11. Offset Lockout relay

12. Down Latch Release relay

13. Down Float Latch relay

14. Hitch Home Verify for Dump relay

Figure 8

2

3

6

8

9

10

11

13

1

5

7

12

14

4

FRONT

RIGHT

The electrical system of the Pro Sweep includes eight

(8) relays used to c ontrol sweeper operation. These re-

lays are identical and are attached to the frame in front

of the RH wheel (Fig. 8). Relays can be identified by a

tag on the wire harness. Refer to circuit drawings in

Chapter 6 -- Electrical Diagrams for additional relay in-

formation.

Relay Operation

The Broom relay is used to control the energizing of hy-

draulic manifold solenoid (SRV). When the Broom relay

is not energized (broom enable proximity switch open),

solenoid (SRV) will not be energized and the broom will

be stationary (not rotating). When the Broomrelay is en-

ergized (broom enable proximity switch closed), s ole-

noid (SRV) will be energized to allow hydraulic flow to

the broom motor so the broom will rotate.

The Down Latch Release and Down Float Latch relays

are used to control the sweeper down function. These

relays ensure that the sweeper continues to lower when

the operator presses the remote transmitter sweeper

down button.The relays are also used to stop the lower-

ing of the sweeper when the operator presses either the

stop or up button on the remote transmitter.

The Logic Inverter relay is used to stop the sweeper

down function. During normal sweeper operation, the

Logic Inverter r elay is energized by the remote receiver

which allows the operator to initiate the sweeper down

function with the remote transmitter. When the operator

presses the remotetransmitterstop button, theLogic In-

verter relay is de--energized which causes the sweeper

down function to stop.