Pro Sweep Page 4 -- 7 Electrical System

Adjustments

Proximity Switches

The Pro Sweep uses five (5) identical inductive proximi-

ty switches tocontrolsweeper operation. These proxim-

ity switches are normally open and close when a

sweeper frame component is positioned near the target

end of the switch. The switches incorporate a LED on

the cable end of the switch. The LED illuminates when

the switch is in the closed position. The switches are

mounted on the main sweeper frame in three (3) loca-

tions. Refer to Proximity Switches in the Component

Testing section for additional switch information.

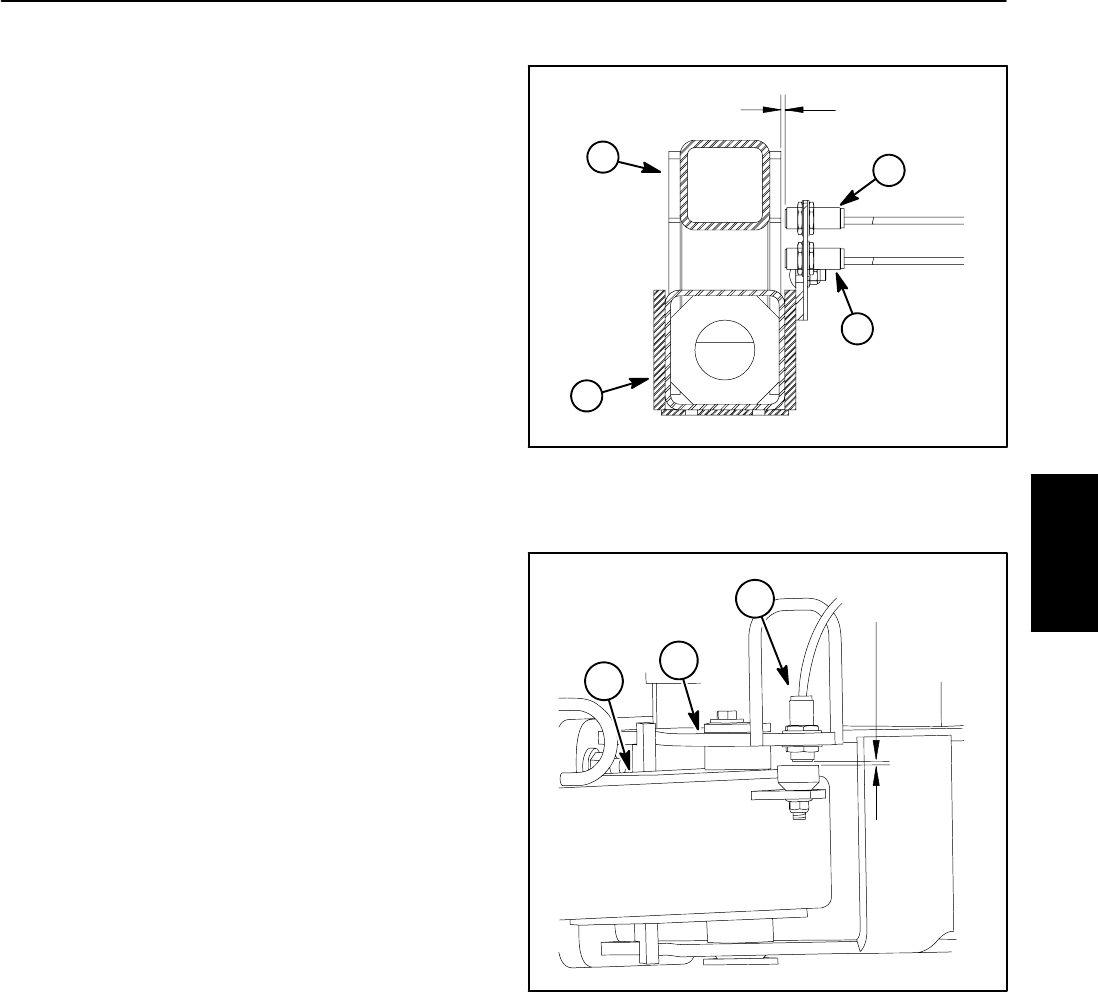

Proximity Switch Adjustment

1. Position sweeper on a level surface with dump hop-

per empty and lowered. Have sweeper attached to tow-

ing vehicle with the sweeper positioned directly behind

the tow vehicle (not offset). Engage vehicle parking

brake, stop engine and remove key from the ignition

switch. Chock sweeperwheels to preventsweeper from

moving.

2. The target surface end of proximity switch should be

from 0.110” to 0.170” (2.8 to 4.3 mm) from sensing plate

on sweeper (Figs. 2 and 3).

3. If necessary, loosen jam nuts on switch and adjust

switch location to allow proper clearance between

switch and sensing plate.

4. After adjustment, torque jam nuts from 165 to 195

in--lb (18.7 to 22.0 N--m). After tightening jam nuts,

check that clearance between end of proximity switch

and sensing plate has not changed.

5. After adjustmentiscomplete,makesurethatproxim-

ity switch connector is plugged into sweeper wire har-

ness.

1. Main frame

2. Pitch frame

3. Proximity switch

Figure 2

0.110 to 0.170”

(2.8 to 4.3 mm)

1

3

2

3

1. Main frame

2. Tongue hitch

3. Proximity switch

Figure 3

0.110 to 0.170”

(2.8 to 4.3 mm)

2

1

3

Electrical

System