Pro SweepHydraulic System Page 3 -- 24

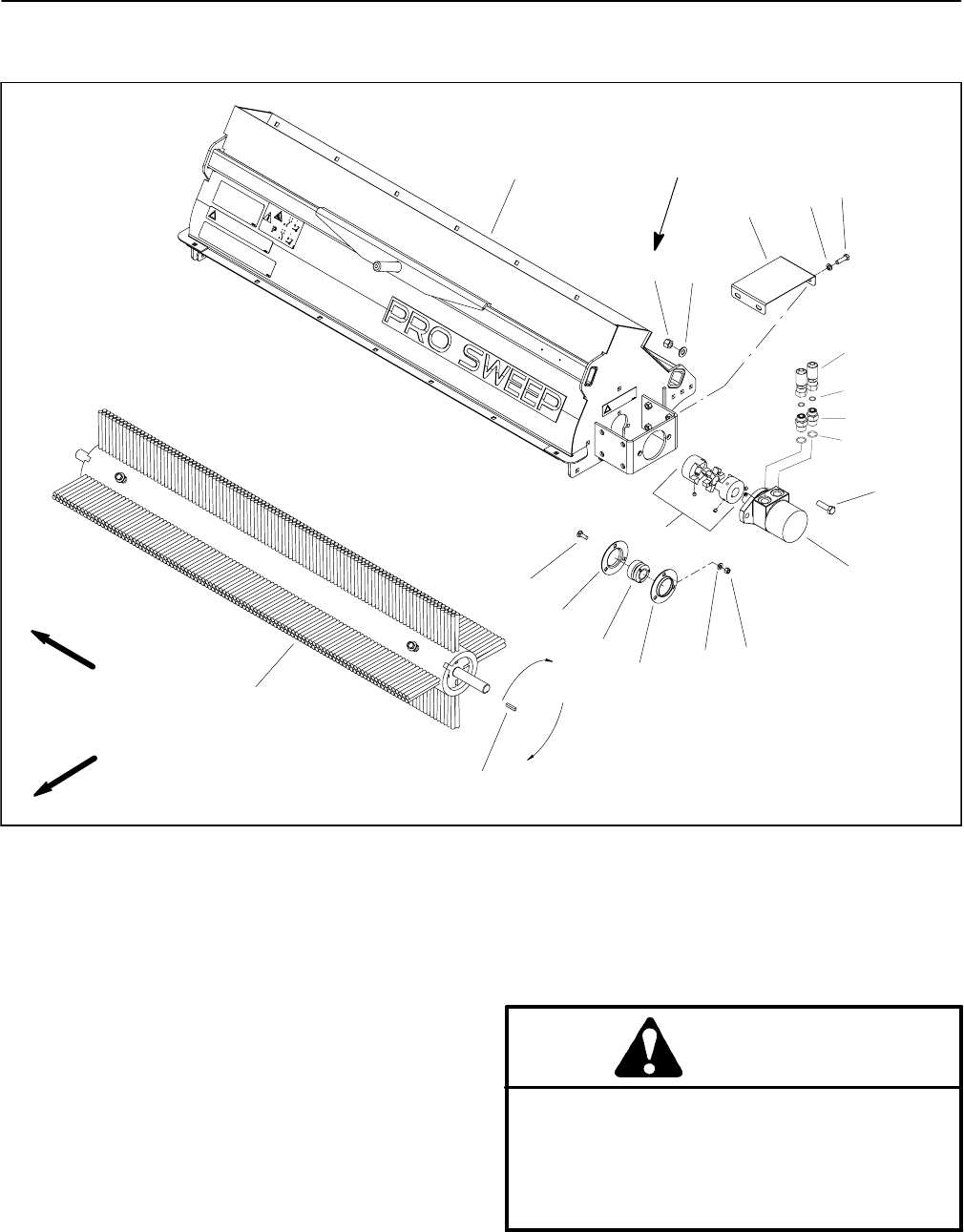

Brush Motor

1. Brush housing

2. Coupling cover (2 used)

3. Lock washer (8 used)

4. Cap screw (8 used)

5. Lock nut (2 used)

6. Flat washer (2 used)

7. Carriage bolt (6 used)

8. Coupling assembly

9. Hydraulic hose (2 used)

10. O--ring (2 used)

11. Hydraulic fitting (2 used)

12. O--ring (2 used)

13. Cap screw (2 used)

14. Hydraulic brush motor

15. Flat washer (6 used)

16. Lock nut (6 used)

17. Bearing flange (4 used)

18. Square key

19. Brush assembly

20. Bearing assembly

Figure 13

FRONT

RIGHT

94 to 116 ft--lb

(128 to 157 N--m)

2

3

6

8

9

10

11

13

1

5

7

12

14

15

16

17

18

19

4

17

20

Removal (Fig. 13)

1. Position sweeper on a level surface with dump hop-

per empty and fully lowered. Chock sweeper wheels to

prevent sweeper from moving. If sweeper is attached to

tow vehicle, apply tow vehicle parking brake, stop en-

gine and remove key from the ignition switch.

CAUTION

Before disconnecting any hydraulic compo -

nents, operate all sweeper hydraulic controls to

relieve system pressure and avoid injury from

pressurized hydraulic oil. See Relieving Hydrau-

lic System Pressure in the General Information

section of this chapter.