21

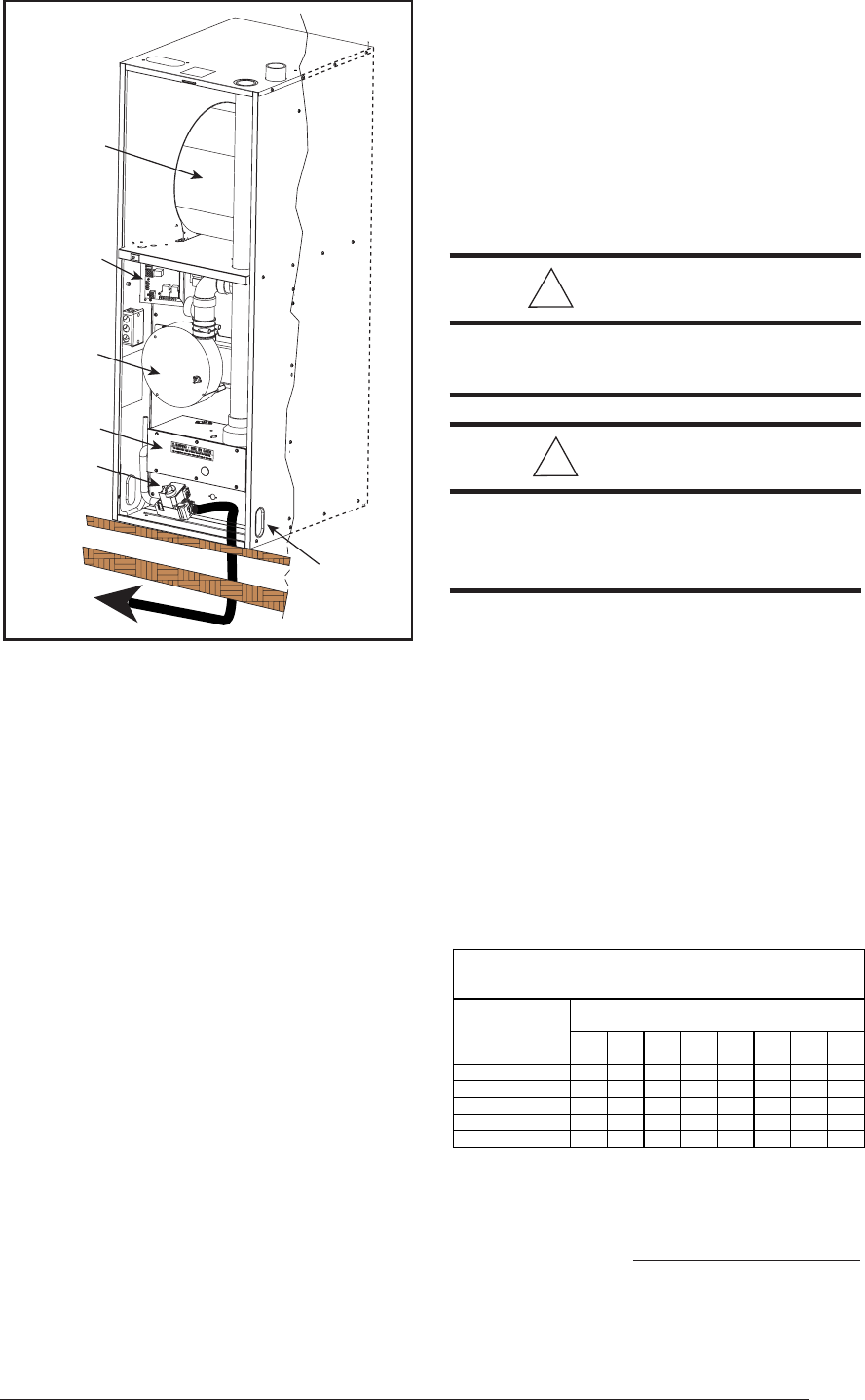

Figure 22. Typical Gas Piping

Table 7. Capacity of Black Iron Gas Pipe

(cu. ft. per hour) for Natural Gas

(specific gravity = .60)

To Gas

Supply

Floor

Inducer

Alt. Gas

Line Entry

Floor Cavity

Gas

Valve

Burner

Box

Control

Board

Main

Blower

NOMINAL LENGTH OF PIPE RUN

BLACK IRON (feet)

PIPE DIAMETER

(in.) 1020304050607080

1/2 130 90 75 65 55 50 45 40

3/4 280 190 150 130 115 105 95 90

1 520 350 285 245 215 195 180 170

1 1/4 1050 730 590 500 440 400 370 350

1 1/2 1600 1100 890 760 670 610 560 530

CAPACITY OF BLACK IRON GAS PIPE (CU. FT. PER HOUR)

FOR NATURAL GAS (SPECIFIC GRAVITY - 0.60)

The cubic feet per hour listed in the table above must be greater than

the cubic feet per hour of gas flow required by the furnace.

To determine the cubic feet per hour of gas flow required by the furnace,

divide the input rate of the furnace by the heating value of the gas:

Cubic Feet Input To Furnace (Btu/hr)

Per Hour Required Heating Value of Gas (Btu/Cu. Ft.)

=

If the test pressure is less than or equal to 1/2

psig (14 in. water column), the furnace must be

isolated from the gas supply line by closing the

manual shut-off valve.

Leak Check

After the gas piping to the furnace is complete,

all connections must be tested for gas leaks. To

check for leaks use only a soap and water solu-

tion or other approved method.

High Altitude Derate

The nameplate input rating for the furnaces

apply for elevations up to 4,000 feet above sea

level for US and Canada. If the elevation for the

furnace location is higher than 4,000 feet above

sea level, the furnace input must be derated by

using the appropriate orifice size listed in

Table 8.

NOTE: The density of air decreases with in-

creasing elevation above sea level. This re-

duces the quantity of combustion air drawn into

the furnace under normal operation and requires

the unit be derated by using smaller gas orifices

or lower manifold pressure.

CONVERSION

This furnace can be converted from the fac-

tory-equipped gas to either natural gas (for LP

gas ready models), or LP gas (for natural gas

ready models). Conversions must be made by

qualified service personnel, using only factory

authorized or approved parts. The required

conversion orifices are supplied with the fur-

nace.

!

WARNING:

DO NOT REMOVE OR DEFACE THE

ORIGINAL RATING PLATE.

!

CAUTION:

The gas supply shall be shut off prior to

disconnecting the electrical power,

before proceeding with the conversion.

To Turn Off Fuel Supply to the Appliance:

1. Set the room thermostat to “OFF” or its

lowest temperature setting.

2. Turn OFF the main gas supply to the appli-

ance at the manual valve, outside of the

appliance casing.

3. Remove the control access panel / lou-

vered door.

4. Move the appliance gas valve lever/knob to

the “OFF” position.

5. Turn OFF the electrical power to the appli-

ance.