69Heat & Glo • XLR-PLUS-N-AU, XLR-PLUS-PB-AU • 2264-900 Rev. M • 7/12

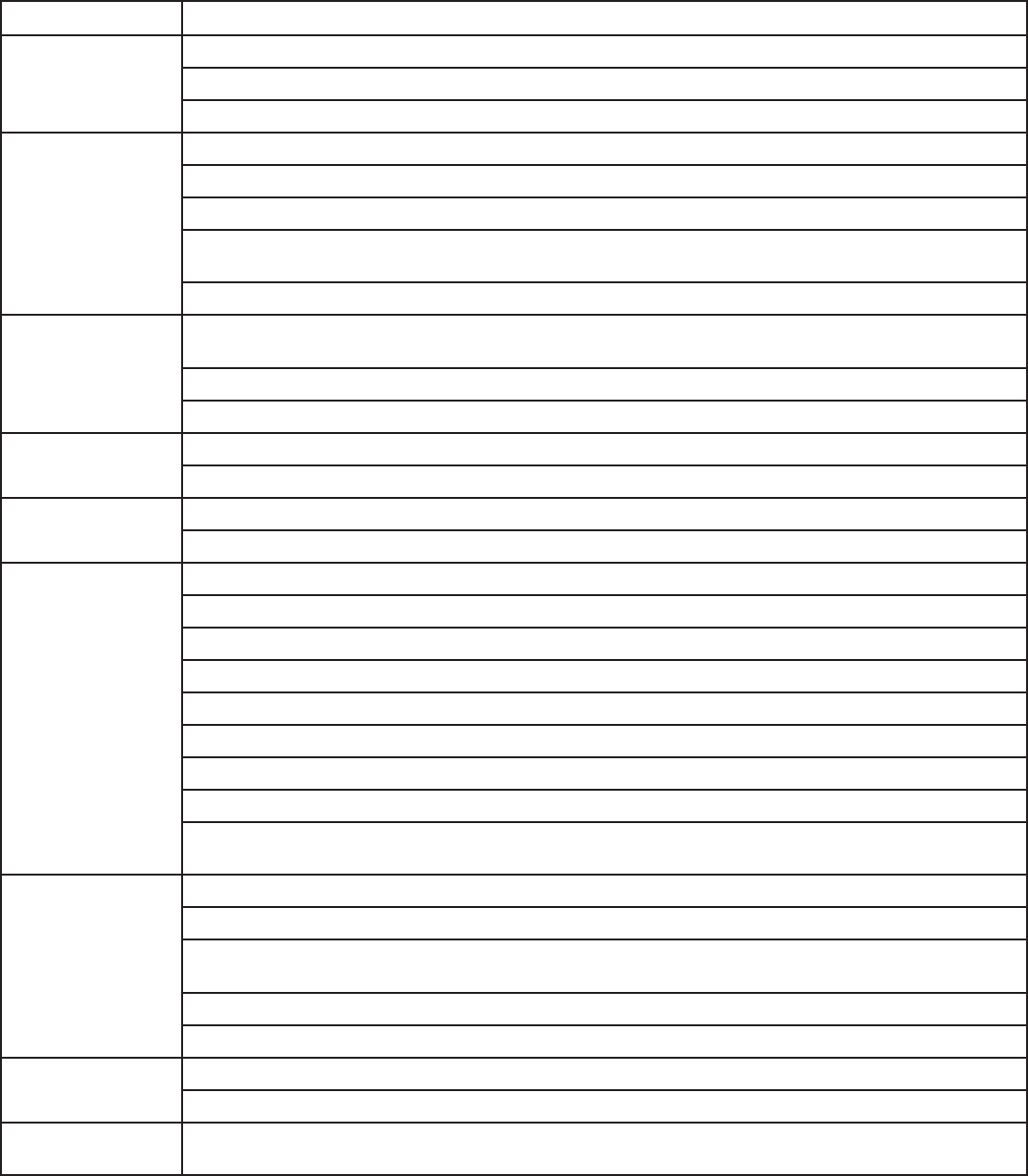

B.MaintenanceTasks

Inspect MaintenanceTasks

Doors 1. Inspect for scratches, dents or other damage and repair as necessary.

2. Verify no obstructions to airow.

3. Verify maintenance of proper clearance to combustible household objects.

Gasket Seal, Glass

Assembly and Glass

1. Inspect gasket seal and its condition.

2. Inspect glass panels for scratches and nicks that can lead to breakage when exposed to heat.

3. Conrm there is no damage to glass or glass frame. Replace as necessary.

4. Verify that latches engage properly, clip studs are not stripped, and glass attachment components are intact

and operating properly. Replace as necessary.

5. Clean glass. Replace glass assembly if severely coated with silicate deposits that cannot be removed.

Valve Compartment

and Firebox Top

1. Vacuum and wipe out dust, cobwebs, debris or pet hair. Use caution when cleaning these areas. Screw tips

that have penetrated the sheet metal are sharp and should be avoided.

2. Remove any foreign objects.

3. Verify unobstructed air circulation.

Logs 1. Inspect for broken, damaged, or missing logs. Replace as necessary.

2. Verify correct log placement and no ame impingement causing sooting. Correct as necessary.

Firebox 1. Inspect for paint condition, warpage, corrosion or perforation. Sand and repaint as necessary.

2. Replace appliance if rebox has been perforated.

Burner Ignition and

Operation

1. Verify burner is properly secured and aligned with pilot or igniter.

2. Clean off burner top, inspect for plugged ports, corrosion or deterioration. Replace burner if necessary.

3. Replace ember materials with new dime-size and shape pieces. Do not block ports or obstruct lighting paths.

4. Check for smooth lighting and ignition carryover to all ports. Verify there is no ignition delay.

5. Inspect for lifting or other ame problems.

6. Inspect orice for soot, dirt or corrosion.

7. Verify manifold and inlet pressures. Adjust regulator as required.

8. Inspect pilot ame strength. Clean or replace orice as necessary.

9. Inspect thermocouple/thermopile or IPI sensor rod for soot, corrosion and deterioration. Polish with ne steel

wool or replace as required.

Flueing 1. Inspect venting for blockage or obstruction such as bird nests, leaves, etc.

2. Conrm that termination cap remains clear and unobstructed by plants, etc.

3. Verify that termination cap clearance to subsequent construction (building additions, decks, fences or sheds)

has been maintained.

4. Inspect for corrosion or separation.

5. Verify weather stripping, sealing and ashing remains intact.

Remote controls 1. Verify operation of remote.

2. Replace batteries in remote transmitters and battery-powered receivers.

Carbon Deposition 1. Appliances incorporating a live fuel effect, and designed to operate with luminous ames, may exhibit slight

carbon deposition.