37Heat & Glo • XLR-PLUS-N-AU, XLR-PLUS-PB-AU • 2264-900 Rev. M • 7/12

C. SecureTheVentSections

• Vertical runs of pipe must be supported every 8 ft. (2.44 m).

• Horizontal sections must be supported every 5 ft. (1.52

m).

• Vent supports or plumbers strap (spaced 120º apart)

may be used to support. See Figures 10.5 and 10.6.

• Wall shield restops may be used to provide horizontal

support.

• Ceiling restops have tabs that may be used to provide

vertical support.

WARNING! Risk of Fire, Explosion or Asphyxiation!

Improper support may allow vent to sag and separate.

Use vent run supports and connect vent sections per in-

stallation instructions. DO NOT allow vent to sag below

connection point to appliance.

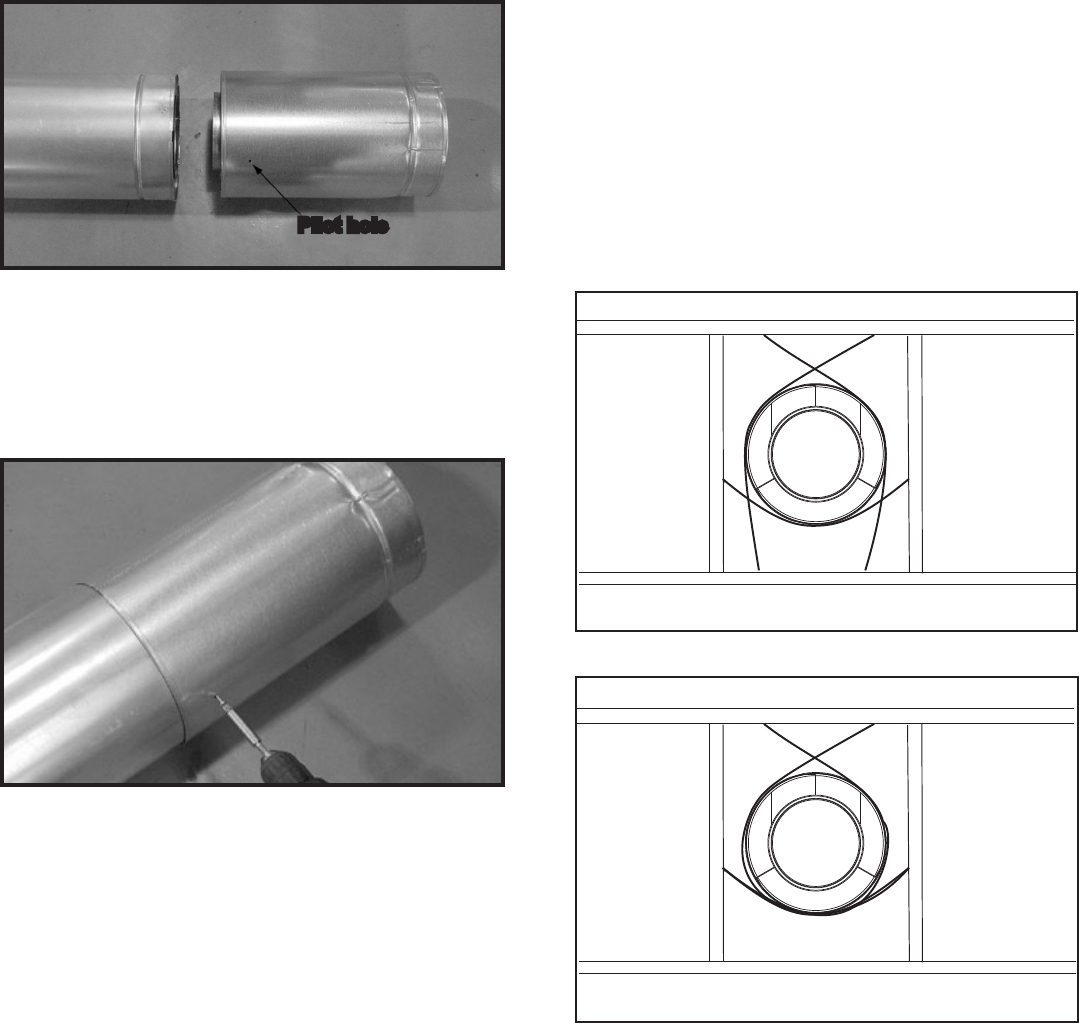

Figure10.5SecuringVerticalPipeSections

Figure10.6SecuringHorizontalPipeSections

B. AssembleSlipSections

• Slide the inner ue of the slip section into the inner ue of

the pipe section and the outer ue of the slip section over

the outer ue of the pipe section. See Figure 10.3.

• Slide together to the desired length.

Figure10.3SlipSectionPilotHoles

Figure10.4ScrewsintoSlipSection

Pilothole

• Continue adding pipe as necessary following instructions

in “Assembling Pipe Sections.”

NOTICE: If slip section is too long, the inner and outer ues

of the slip section can be cut to the desired length.

NOTICE: When installing a vent system with an HRC

termination cap, all pipe system joints shall be sealed using

a high temperature silicone sealant.

• Apply a bead of silicone sealant inside the female outer

pipe joint prior to joining sections.

• Only outer pipes are sealed, sealing the inner ue is not

required.

• All unit collar, pipe, slip section, elbow and cap outer

ues shall be sealed.

• Maintain a 1-1/2 in. (38 mm) overlap between the slip

section and the pipe section.

• Secure the pipe and slip section with two screws no

longer than 1/2 in. (13 mm), using the pilot holes in the

slip section. See Figure 10.4.