Heat & Glo • XLR-PLUS-N-AU, XLR-PLUS-PB-AU • 2264-900 Rev. M • 7/12 16

B. MaintenanceTasks-QualiedService

Technician

The following tasks must be performed by a qualied ser-

vice technician.

GasketSealandGlassAssemblyInspection

Frequency:Annually

By:Qualied Service Technician

Toolsneeded: Protective gloves, drop cloth and a stable

work surface.

• Inspect gasket seal and its condition.

• Inspect xed glass assembly for scratches and nicks that

can lead to breakage when exposed to heat.

• Conrm there is no damage to glass or glass frame.

Replace as necessary.

• Verify that xed glass assembly is properly retained and

attachment components are intact and not damaged.

Replace as necessary.

Firebox

Frequency:Annually

By:Qualied Service Technician

Toolsneeded: Protective gloves, sandpaper, steel wool,

cloths, mineral spirits, primer and touch-up paint.

• Inspect for paint condition, warped surfaces, corrosion

or perforation. Sand and repaint as necessary.

• Replace replace if rebox has been perforated.

ControlCompartmentandFireboxTop

Frequency:Annually

By:Qualied Service Technician

Toolsneeded: Protective gloves, vacuum cleaner, dust

cloths

• Vacuum and wipe out dust, cobwebs, debris or pet hair.

Use caution when cleaning these areas. Screw tips that

have penetrated the sheet metal are sharp and should

be avoided.

• Remove all foreign objects.

• Verify unobstructed air circulation.

GasPressureInformation

Frequency: Upon initial installation and gas valve re-

placement or service.

By:Qualied Service Technician

Toolsneeded: Protective gloves, manometer, ashlight,

screw driver set.

• Gas pressure taps are accessible by removing the deco-

rative front and xed glass assembly. Refer to Section

11.A for information related to the gas valve and gas

pressure settings.

BurnerIgnitionandOperation

Frequency:Annually

By:Qualied Service Technician

Toolsneeded: Protective gloves, vacuum cleaner, whisk

broom, ashlight, voltmeter, indexed drill bit set, and a

manometer.

• Verify burner is properly secured and aligned with pilot

or igniter.

• Clean off burner top, inspect for plugged ports, corrosion

or deterioration. Replace burner if necessary.

• Check for smooth lighting and ignition carryover to all

ports. Verify that there is no ignition delay.

• Inspect for lifting or other ame problems.

• Verify air shutter setting is correct. See Section 14.G for

required air shutter setting. Verify air shutter is clear of

dust and debris.

• Inspect orice for soot, dirt and corrosion. Verify orice

size is correct. See Service Parts List for proper orice

sizing.

• Verify manifold and inlet pressures. Adjust regulator as

required.

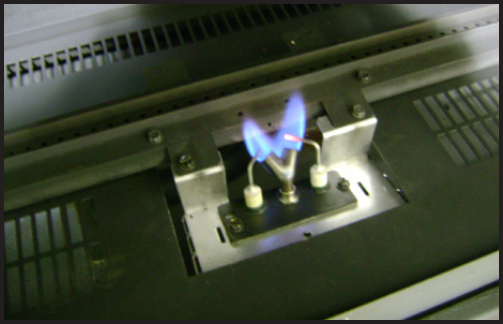

• Inspect pilot ame pattern and strength. See Figure 3.1

for proper pilot ame pattern. Clean or replace orice

spud as necessary.

• Inspect IPI ame sensing rod for soot, corrosion and

deterioration. Polish with ne steel wool or replace as

required.

• Verify that there is not a short in ame sense circuit

by checking continuity between pilot hood and ame

sensing rod. Replace pilot as necessary.

Figure3.1IPIPilotFlamePattern