R-5627 Page 19

Installing the Vent System in a Chase

A chase is a vertical box like structure built to enclose the gas appliance

and/or it's vent system. Vertical vent runs on the outside of a building

may be, but are not required to be installed inside a chase.

Figure 35

CAUTION: Treatment of firestop spacers and construction of the

chase may vary with the type of building. These instructions are not

substitutes for the requirements of local building codes. Therefore,

your local building codes must be checked to determine the

requirements for these steps.

NOTE: When installing this vent system in a chase, it is always good

building practice to insulate the chase as you would the outside walls of

your home. This is especially important for cold climate installations.

Upon completion of building your chase framing, install the vent system

by following the instructions in this manual. Remember to build the

chase large enough so that minimum clearance of combustible materials

(including insulation) to the vent system are maintained.

Reassembly and Resealing Vent Pipe System

Attach adapter pipe to vent cover in either the vertical or horizontal

position, replace horizontal and vertical pipe lengths, elbows and

horizontal or vertical termination kit.

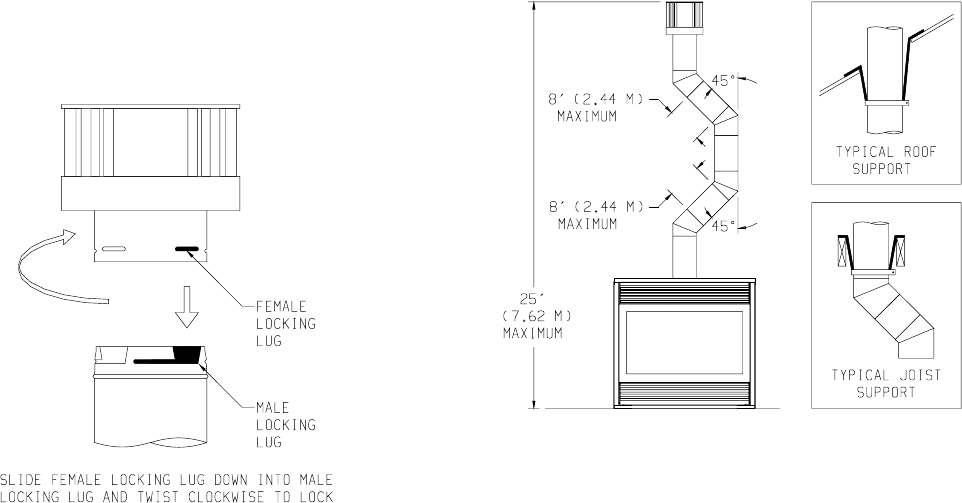

All vent system components lock into place by sliding the concentric

pipe section with four (4) equally spaced interior beads onto the

appliance collar or previously installed component end with four (4)

equally spaced indented sections. When the internal beads of each

starting 6-5/8 inch outer pipe line up, rotate pipe section clockwise 90°

(approximately 3 inches). The vent pipe is now locked together.

Continue replacing components per the vent system configuration. Be

certain that each succeeding vent component is securely fitted and

locked into the preceding component in the vent system.

Vertical Through the Roof Applications (Figure 36)

Your Gas Fireplace has been approved for:

a) Vertical installations up to 25 feet in height.

b) Two sets of 45 degree elbow offsets within these vertical installations.

From 0 to a maximum of 8 ft. a vent pipe can be used between

elbows.

c) Wall straps must be used to support offset pipe every 4'.

This applications will require that you first determine the roof pitch and

use the appropriate venting components.

Figure 36

Leak Testing Gas Line

Consult the current National Fuel Gas Code, ANSI Z223.1 CAN/CGA-

B149 (.1 or .2) installation code.

Compounds used on threaded joints of gas piping shall be resistant to the

action of liquefied petroleum gases. The gas lines must be checked for

leaks by the installer. This should be done with a soap solution watching

for bubbles on all exposed connections, and if unexposed, a pressure test

should be made.

Never use an exposed flame to check for leaks. Appliance must be

disconnected from piping at inlet of control valve and pipe capped or

plugged for pressure test. Never pressure test with appliance

connected; control valve will sustain damage!

NOTE: The gas control is equipped with a captured screw type pressure

test point, therefore it is not necessary to provide a 1/8" test point up

stream of the control.

A gas valve and ground joint union should be installed in the gas line

upstream of the gas control to aid in servicing. It is required by the

National Fuel Gas Code that a drip line be installed near the gas inlet. This

should consist of a vertical length of pipe tee connected into the gas line

that is capped on the bottom in which condensation and foreign particles

may collect.

When using copper or flex connector use only approved fittings. Always

provide a union so that gas line can be easily disconnected for burner or

fan servicing. See gas specification for pressure details and ratings.

The appliance and it's individual shut off valve must be disconnected from

supply piping system during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5kPa).

The appliance must be isolated from the gas supply piping system by

closing its individual manual shut off valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than 1/

2 psig (3.5kPa).

Attention! If one of the procedures results in pressures in excess of 1/2

psig (14" w.c.) (3.5 kPa) on the fireplace gas valve, it will result in a

hazardous condition

.