MAINTENANCE

To ensure continuing high performance, and to minimize

the possibility of premature equipment failure, periodic main-

tenance must be performed on this equipment. This cooling

unit should be inspected at least once each year by a quali-

fied service person. To troubleshoot cooling of units, refer to

Troubleshooting chart in back of book.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools and equipment. If you do not possess these, do not

attempt to perform any maintenance on this

equipment, other than those procedures recommended

in the User’sManual. FAILURE TO HEED THISWARN-

ING COULD RESULT IN SERIOUS PERSONAL IN-

JURY AND POSSIBLE DAMAGE TO THIS EQUIP-

MENT.

The minimum maintenance requirements for this equip-

ment are as follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness and check

lubrication each cooling season. Clean and lubricate (if

required) when necessary. For first heating season, in-

spect blower wheel bimonthly to determine proper clean-

ing frequency.

4. Check electrical connections for tightness and controls

for proper operation each cooling season. Service when

necessary.

Failure to follow these warnings could result in serious

personal injury:

1. Turn off electrical power to the unit before perform-

ing any maintenance or service on the unit.

2. Use extreme caution when removing panels and parts.

As with any mechanical equipment, personal injury

can result from sharp edges.

3. Never place anything combustible either on, or in con-

tact with, the unit.

Air Filter

Never operate the unit without a suitable air filter in the

return-air duct system. Always replace the filter with the

same dimensional size and type as originally installed.

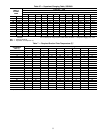

See Tables 1 and 2 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway-type) or clean (cleanable-type) at least twice dur-

ing each cooling season or whenever thefilters become clogged

with dust and lint.

Replace filters with the same dimensional size and type as

originally provided, when necessary.

Unit Top Removal

NOTE: When performing maintenance or service proce-

dures that require removal of the unit top, be sure to

perform all of the routine maintenance procedures that re-

quire top removal, including coil inspection and cleaning,

and condensate drain pan inspection and cleaning.

Only qualified service personnel should perform mainte-

nance and service procedures that require unit top removal.

Refer to the following top removal procedures:

1. Remove7 screws on unit topcover surface. (Save allscrews.)

2. Remove 4screws on unit top cover flange. (Save all screws.)

3. Lift top from unit carefully. Set top on edge and make

sure that top is supported by unit side that is opposite

duct (or plenum) side.

4. Carefully replace and secure unit top to unit, using screws

removed in Steps 1 and 2, when maintenance and/or serv-

ice procedures are completed.

Evaporator Blower and Motor

NOTE: Motors without oilers are prelubricated. Do not at-

tempt to lubricate these motors.

For longer life, operating economy, and continuing effi-

ciency, clean accumulated dirt and grease from the blower

wheel and motor annually.

Lubricate the motor every 5 years if the motor is used in-

termittently (thermostat FAN switch in AUTO. position), or

every 2 years if the motor is used continuously (thermostat

FAN switch in ON position).

Disconnect and tag electrical power to the unit before

cleaning and lubricating the blower motor and wheel.

Failure to adhere to this warning could cause personal

injury or death.

To clean and lubricate the blower motor and wheel:

1. Remove and disassemble blower assembly as follows:

a. Remove blower access door.

b. For standard non-ICM units, disconnect motorlead from

IFR. Disconnect yellow motor lead from terminal L2

of the contactor.

c. Remove blower assembly from all units. Be careful

not to tear insulation in blower compartment.

d. Ensure proper reassembly by marking blower wheel

and motor in relation to blower housing before

disassembly.

e. Loosen setscrew(s) which secure wheel to motor shaft.

Remove screws that secure motor mount brackets to

housing and slide motor and motor mount out of

housing.

2. Lubricate motor as follows:

a. Thoroughly clean all accumulations of dirt or grease

from motor housing.

b. Remove dust caps or plugs from oil ports located at

each end of motor.

c. Use a good grade of SAE 20 nondetergent motor oil

and put one teaspoon (

1

⁄

16

oz. or 16 to 25 drops) in

each oil port.

d. Allow time for oil to be absorbed by each bearing,

then wipe excess oil from motor housing.

e. Replace dust caps or plugs in oil ports.

3. Remove and clean blower wheel as follows:

a. Ensure proper reassembly by marking wheel orienta-

tion and cutoff plate location.

b. Remove screws holding cut-off plate, and remove plate

from housing.

40