Step 5 — Select and Install Ductwork — The de-

sign and installation of the duct system must be in accor-

dance with the standards of the NFPA (National Fire Protec-

tion Association) for installation of nonresidence-type air

conditioning and ventilating systems, NFPA90Aor residence-

type,NFPA90B;and/orlocalcodesandresidence-type,NFPA90B;

and/or local codes and ordinances.

Select and size ductwork, supply-air registers and

return-air grilles according to ASHRAE (American Society

of Heating, Refrigeration, and Air Conditioning Engineers)

recommendations.

The unit has duct flanges on the supply- and return-air

openings on the side of the unit. See Fig. 2-9 for connection

sizes and locations.

When designing and installing ductwork, consider the

following:

When connecting ductwork to units, do not drill deeper

than

1

⁄

2

inch in shaded area shown in Fig. 13 or coil may

be damaged.

• All units should have field-supplied filters or accessory fil-

ter rack installed in the return-air side of the unit. Rec-

ommended sizes for filters are shown in Tables 1 and 2.

• Avoid abrupt duct size increases and reductions. Abrupt

change in duct size adversely affects air performance.

IMPORTANT: Use flexible connectors between

ductwork and unit to prevent transmission of vibra-

tion. Use suitable gaskets to ensure weathertight and

airtight seal. When electric heat is installed, use fire-

proof canvas (or similar heat resistant material) con-

nector between ductwork and unit discharge connec-

tion. If flexible duct is used, insert a sheet metal sleeve

inside duct. Heat resistant duct connector (or sheet metal

sleeve) should extend 24-in. from electric heater

element.

• Size ductwork for cooling air quantity (cfm). The mini-

mum air quantity for proper electric heater operation is

listed in Table 3. Heater limit switches may trip at air quan-

tities below those recommended.

• Insulate and weatherproof all external ductwork. Insulate

and cover with a vapor barrier all ductwork passing through

conditioned spaces. Follow latest Sheet Metal andAir Con-

ditioning Contractors National Association (SMACNA)

andAir Conditioning ContractorsAssociation (ACCA) mini-

mum installation standards for residential heating and air

conditioning systems.

• Secure all ducts to building structure. Flash, weather-

proof, and vibration-isolate duct openings in wall or roof

according to good construction practices.

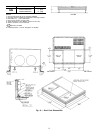

Figure 14 shows a typical duct system with 50SS,SX

installed.

Table 3 — Minimum Airflow for Safe Electric

Heater Operation (Cfm)

SIZE

018* 024 030 036 042 048 060

700 700 875 1200 1225 1400 1750

*Unit 50SS only.

CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOWNFLOW (VERTICAL) DISCHARGE — STD (Non-

Integrated Control Motor [Non-ICM] UNITS — Units are

shipped in a horizontal configuration. To convert a horizon-

tal unit for downflow (vertical) discharge, perform the fol-

lowing steps:

Before performing service or maintenance operations on

system, turn off main power to unit. Turn off accessory

heater power switch if applicable. Electrical shock can

cause personal injury.

1. Open all electrical disconnects before starting any serv-

ice work.

2. Remove evaporator coil access panel (Fig. 15).

3. Locate lances in basepan insulation that are placed over

the perimeter of the vertical duct opening cover

(Fig. 16).

4. Using a straight edge and sharp knife, cut and remove

the insulation around the perimeter of the cover. Re-

move the screws securing the cover to the basepan and

slide out the cover. Discard the cover (Fig. 17).

Fig. 13 — Area Not To Be Drilled

Power Wiring

Control Wiring

Condenser Airflow

Evaporator Airflow

*Separate disconnect per NEC

(NationalElectrical Code)required

for electric heater when single-

point connection is not used.

Fig. 14 — Typical Installation

16