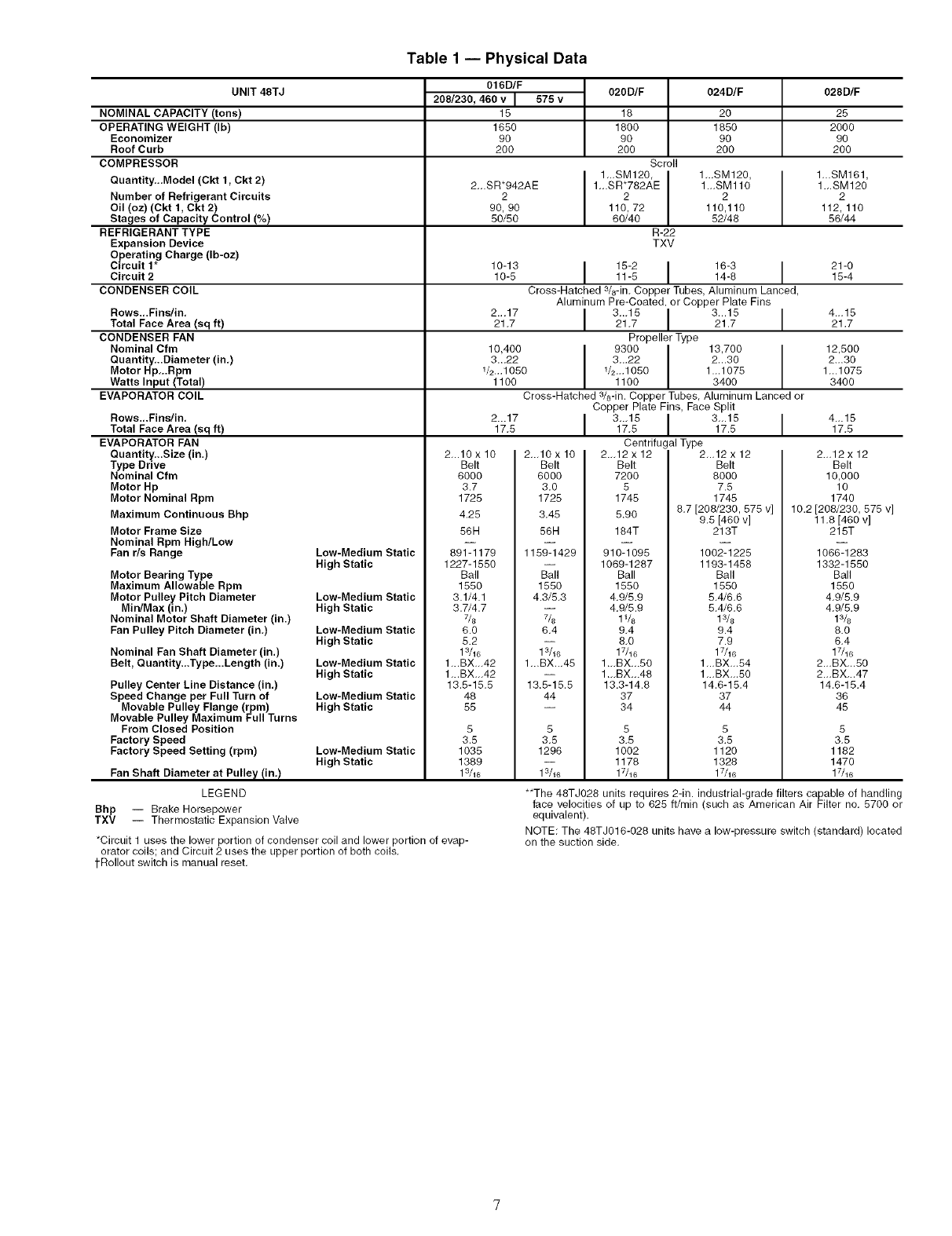

Table 1 -- Physical Data

016D/F

UNIT 48TJ 020D/F 024D/F 028D/F

208/230, 460 v I 575 v

NOMINAL CAPACITY (tons) 15 18 20 25

OPERATING WEIGHT (Ib) 1650 1800 1850 2000

Economizer 90 90 90 90

Roof Curb 200 200 200 200

COMPRESSOR Scroll

1...SM120, 1...SM120, 1...SM161,

Quantity,.,Model (Ckt 1, Ckt 2) 2_.SR*942AE 1_.SR*782AE 1._SM110 1_.SM120

Number of Refrigerant Circuits 2 2 2 2

Oil (oz) (Ckt 1, Ckt 2) 90, 90 110, 72 110,110 112, 110

Stages of Capacity Control (%) 50/50 60/40 52/48 56/44

REFRIGERANT TYPE R-22

Expansion Device TXV

Operating Charge (Ib-oz)

c,rcu,t,* 10-13 I 15-2I 16-3 I 21-0Circuit 2 10-5 11-5 14-8 15-4

CONDENSER COIL Cross-Hatched 3/8-in. Copper Tubes, Aluminum Lanced,

Aluminum Pre-Coated, or Copper Plate Fins

Rows...Fins/in. 2...17 I 3_.15 I 3...15 I 4...15

Total Face Area (sq ft) 21.7 21.7 21.7 21.7

CONDENSER FAN Propeller Type

Nominal Cfm 10,400 9300 13,700 12,500

Quantity,..Diameter (in.) 3...22 3..,22 2...30 2...30

Motor Hp...Rpm V2...1050 V2._1050 1..,1075 1.,.1075

Watts Input (Total) 1100 1100 3400 3400

EVAPORATOR COIL Cross-Hatched 3/8-in. Copper Tubes, Aluminum Lanced or

Copper Plate Fins, Face Split

2...17 I 3...15 I 3_.15 I 4_.15

17.5 17.5 17.5 17.5

Centrifugal Type

Rows...Fins/in.

Total Face Area (sq ft)

EVAPORATOR FAN

Quantity...Size (in.)

Type Drive

Nominal Cfm

Motor Hp

Motor Nominal Rpm

Maximum Continuous Bhp

Motor Frame Size

Nominal Rpm High/Low

Fan r/s Range

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Diameter

Min/Max (in.)

Low-Medium Static

High Static

Nominal Motor Shaft Diameter (in.)

Fan Pulley Pitch Diameter (in,)

Nominal Fan Shaft Diameter (in,)

Belt, Quantity...Type...Length (in.)

Pulley Center Line Distance (in.)

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Movable Pulley Maximum Full Turns

From Closed Position

Factory Speed

Factory Speed Setting (rpm)

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

Low-Medium Static

High Static

Fan Shaft Diameter at Pulled/lin.t

LEGEND

Bhp -- Brake Horsepower

TXV -- Thermostatic Expansion Valve

*Circuit 1 uses the lower portion of condenser coil and lower portion of evap-

orator coils; and Circuit 2 uses the upper portion of both coils.

tRollout switch is manual reset.

2,..10 x 10

Belt

6000

3.7

1725

4.25

56H

891-1179

1227-1550

Ball

1550

3.1/4.1

3.7/4.7

7/8

6.0

5.2

13/16

1,..BX_,42

1,..BX_,42

13.5-15.5

48

55

5

3.5

1035

1389

13/16

2,.,10 x 10

Belt

6000

3,0

1725

3,45

56H

1159-1429

Ball

1550

4.3/5,3

7&

6,4

13/16

1,..BX..,45

13.5-15.5

44

2...12 x 12

Belt

7200

5

1745

5.90

184T

910-1095

1069-1287

Ball

1550

4.9/5.9

4.9/5.9

1V8

9,4

8,0

17/16

1.-BX,..50

1.-BX-.48

13.3-14.8

37

34

2...12 x 12

Belt

8000

7.5

1745

8.7 [208/230,575 v]

9.5 [460 v]

213T

1002-1225

1193-1458

Ball

1550

5,4/6,6

5,4/6,6

13/8

9.4

7.9

17/16

1-.BX-.54

1...BX-.50

14.6-15,4

37

44

2._12x12

Belt

10,000

10

1740

10.2 [208/230, 575 v]

11,8 [460 v]

215T

1066-1283

1332-1550

Ball

1550

4,9/5.9

4,9/5.9

lS/s

8.0

6,4

17/16

2..,BX,..50

2..,BX,..47

14.6-15,4

36

45

5 5 5 5

3.5 3.5 3.5 3.5

1296 1002 1120 1182

-- 1178 1328 1470

13/16 17/16 17/16 17/16

**The 48TJ028 units requires 2-in. industrial-grade filters capable of handling

face velocities of up to 625 ft/min (such as American Air Filter no. 5700 or

equivalent).

NOTE: The 48TJ016-028 units have a low-pressure switch (standard) located

on the suction side.