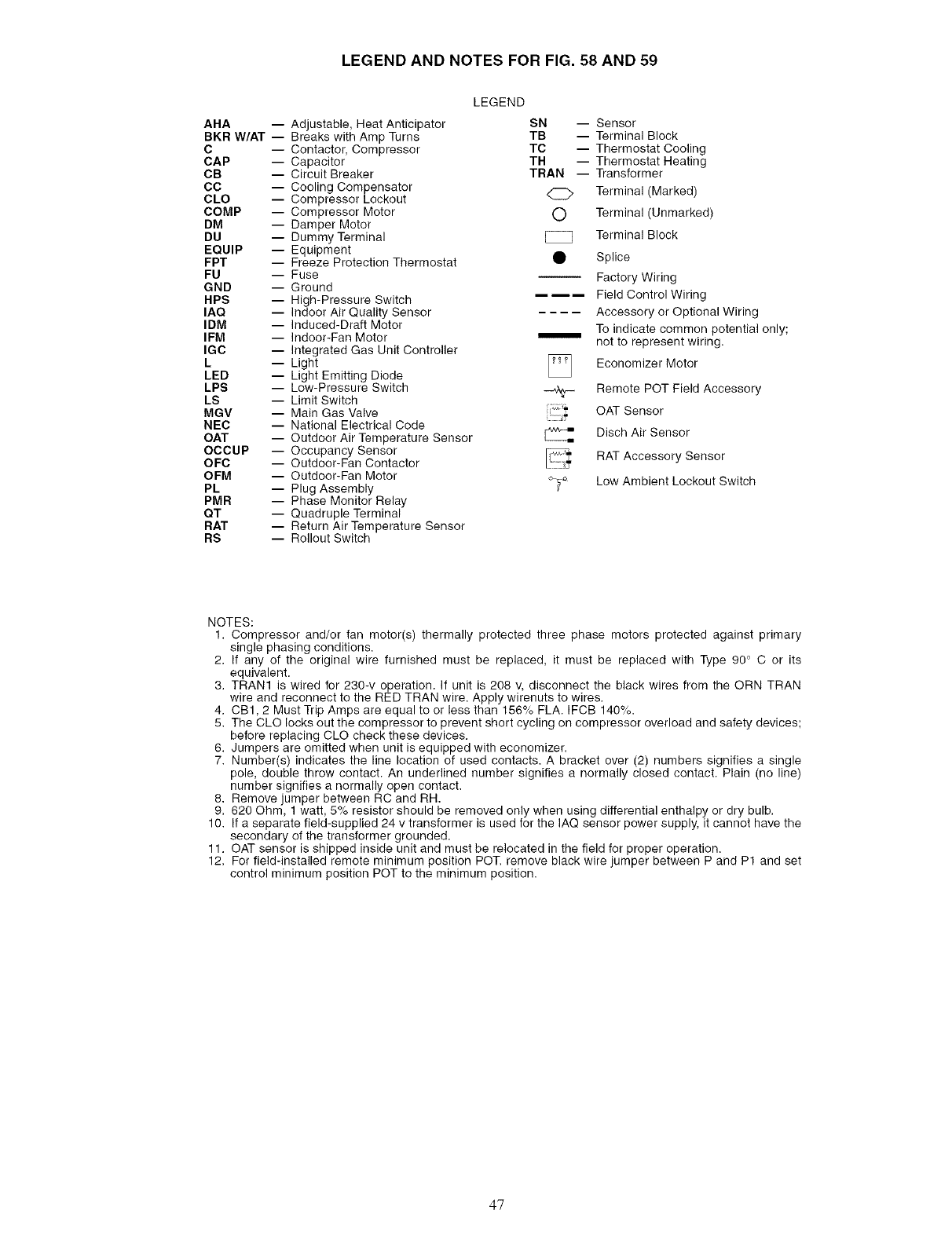

LEGEND AND NOTES FOR FIG. 58 AND 59

LEGEND

AHA -- Adjustable, Heat Anticipator SN -- Sensor

BKR W/AT -- Breaks with Amp Turns TB -- Terminal Block

C -- Contactor, Compressor TC -- Thermostat Cooling

CAP -- Capacitor TH -- Thermostat Heating

CB -- Circuit Breaker TRAN -- Transformer

CC -- Cooling Compensator

CLO -- Compressor Lockout _ Terminal (Marked)

COMP -- Compressor Motor O Terminal (Unmarked)

DM -- Damper Motor

DU -- Dummy Terminal _ Terminal Block

EQUIP -- Equipment

FPT -- Freeze Protection Thermostat • Splice

FU -- Fuse Factory Wiring

GND -- Ground

HPS -- High-Pressure Switch _ m-- Field Control Wiring

IAQ -- Indoor Air Quality Sensor Accessory or Optional Wiring

IDM -- Induced-Draft Motor

IFM -- Indoor-Fan Motor ......m_ To indicate common potential only;

not to represent wiring.

IGC -- Integrated Gas Unit Controller

L -- Light _ Economizer Motor

LED -- Light Emitting Diode

LPS -- Low-Pressure Switch _ Remote POT Field Accessory

LS -- Limit Switch

MGV -- Main Gas Valve OAT Sensor

NEC -- National Electrical Code

OAT -- Outdoor Air Temperature Sensor _ Disch Air Sensor

OCCUP -- Occupancy Sensor RAT Accessory Sensor

OFC -- Outdoor-Fan Contactor

OFM -- Outdoor-Fan Motor Low Ambient Lockout Switch

PL -- Plug Assembly

PMR -- Phase Monitor Relay

QT -- Quadruple Terminal

RAT -- Return Air Temperature Sensor

RS -- Rollout Switch

NOTES:

1. Compressor and/or fan motor(s) thermally protected three phase motors protected against primary

single phasing conditions.

2. If any of the original wire furnished must be replaced, it must be replaced with Type 90 ° C or its

equivalent.

3. TRAN1 is wired for 230-v operation. If unit is 208 v, disconnect the black wires from the ORN TRAN

wire and reconnect to the RED TRAN wire. Apply wirenuts to wires.

4. CB1,2 Must Trip Amps are equal to or less than 156% FLA. IFCB 140%.

5. The CLO locks out the compressor to prevent short cycling on compressor overload and safety devices;

before replacing CLO check these devices.

6. Jumpers are omitted when unit is equipped with economizer.

7. Number(s) indicates the line location of used contacts. A bracket over (2) numbers signifies a single

pole, double throw contact. An underlined number signifies a normally closed contact. Plain (no line)

number signifies a normally open contact.

8. Remove jumper between RC and RH.

9. 620 Ohm, 1watt, 5% resistor should be removed only when using differential enthalpy or dry bulb.

10. If a separate field-supplied 24 v transformer is used for the IAQ sensor power supply, it cannot have the

secondary of the transformer grounded.

11. OAT sensor is shipped inside unit and must be relocated in the field for proper operation.

12. For field-installed remote minimum position POT. remove black wire jumper between P and P1 and set

control minimum position POT to the minimum position.

47