Step 8 -- Install Gas Piping -- Unit is equipped for

use with natured gas. Installation must conform with loc_d

building codes or. in the absence of loc_d codes, with the

National Fuel Gas Code, ANSI Z223.1.

Install field-supplied manu_d gas shutoff valve with a lh-in.

NPT pressme tap for test gage connection at unit. Field gas pip-

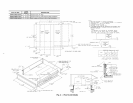

ing must include sediment trap and union. See Fig. 13.

Tlansformer no. 1 is wired for 230-v unit. If 208/230-v unit

is to be run with 208-v power supply, the transformer must be

rewired as follows:

1. Remove cap fiom red (208 v) wire.

2. Remove cap from orange (230 v) spliced wire.

3. Replace orange wire with led wire.

4. Recap both wires.

Do not pressure test gas supply while connected to unit.

Always disconnect union before servicing. Exceeding

maximum manifold pressure may cause explosion and

injury.

I IMPORTANT: Natural gas pressure at unit gas connec-

tion must not be less than 5.5 in. wg or greater than

13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe sm_dler than unit gas connection.

MANUAL SHUTOFF

(FIELD SUPPLIED) _ FT'I

_ _ GAS

PRESSURE TAP

(1/8" NPT PLUG)

UNIT _

o& •---- SEDIMENTTRAP

Fig. 13 -- Field Gas Piping

Step 9 -- Make Electrical Connections

FIELD POWER SUPPLY- Unit is factory wiled for volt-

age shown on nameplate.

When inst_dling units, provide a disconnect per NEC (Na-

tional Electrical Code) of adequate size (Table 5).

All field wiring must comply with NEC and local

requirements.

Route power ground lines through control box end panel or

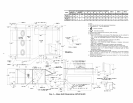

unit basepan (see Fig. 4 and 5) to connections as shown on unit

wiring diagram and Fig. 14.

The correct power phasing is critical in the operation of the

scroll compressol,s. An incorrect phasing will cause the

compressor to rotate in the wrong direction. This may lead

to premature compressor failure.

The unit must be electrically grounded in accor&mce with

local codes and NEC ANSI/NFPA 70 (National Fire Pro-

tection Association) to protect against fire and electric

shock.

Field wiring must confirm to temperature limitations for

type "T" wire. All field wiring must comply with NEC and lo-

cal requirements.

Be certain unused wires ale capped. Failure to do so may

&_magethe transformers.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, voltages

between phases must be balanced within 2%.

Unit failure as a result of operation on improper line voltage

or excessive phase imbalance constitutes abuse and may cause

&Lmage to electrical components.

FIELD CONTROL WIRING -- Install a Carrier-approved

accessory thermostat assembly according to installation in-

structions included with accessory. Ix)cate thermostat assembly

on a solid interior wall in the conditioned space to sense aver-

age temperature.

Route thermostat cable or equivalent single leads of

colored wire from subbase termimds through conduit in unit to

low-voltage connections as shown on unit label wiring diagram

and in Fig. 15.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C minimum). All

wire larger than no. 18 AWG cannot be directly connected at

the thermostat and will require a junction box and splice at the

thermostat.

Set heat anticipator settings as follows:

VO LTAGE W1 W2

208/230,575 0.98 0.44

460 0.80 0.44

Settings may be changed slightly to provide a greater degree

of comfort for a particuku installation.

----1 TBI

II FIELD i _

i_II III I III II_

[ POWER I _

=U.l ....... SUP_PLY

z z

i

I-IN

l EQUIP GND

I

.............. ]

LEGEND

EQUIP -- Equipment

GND -- Ground

NEC -- NationalElectricalCode

TB -- Terminal Block

NOTE:The maximum wire size forTB1 is2/0.

Fig. 14- Field Power Wiring Connections

11