19

18

17

16-

15

<

E14

13

12

11

lO

9

40

I

LED ON

-- - LED OFF

45 50 55

_ED ON

LED O;

_< LED ON-- --

"t,4

I LED OFF

{

65 70 75 80 85 90 95 100

DEGREES FAHRENHEIT

Fig. 38 -- Outside Air Temperature

Changeover Set Points

Outdoor Enthalpy Changeover -- For enthalpy control, tic-

cessoq enthalpy sensor (part number HH57AC078) is

required. Replace the stan&ud outdoor dry bulb temperature

sensor with the accessory enthalpy sensor in the same mount-

ing location. See Fig. 32. When the outdoor tfir enthalpy rises

above the outdoor enth_@y changeover set point, the outdoor-

air damper moves to its minimum position. The outdoor

enthalpy changeover set point is set with the outdoor enthalpy

set point potentiometer on the EconoMiSerIV controllel: The

set points are A, B, C, and D. See Fig. 40. The factory-installed

620-ohm jumper must be in place across terminals SR and SR+

on the EconoMiSerIV controllel: See Fig. 32 and 41.

Differential Enthalpy Control -- For differential enthalpy

control, the EconoMiSerIV controller uses two enthalpy sen-

sors (HH57AC078 and CRENTDIF004A00), one in the out-

side air and one in the return airstream or the EconoMiSerIV

frmne. The EconoMiSerIV controller compares the outdoor tfir

enthalpy to the return tfir enthalpy to determine EconoMiSerIV

use. The controller selects the lower enthalpy air (return or out-

door) for cooling. For example, when the outdoor air has a low-

er enthalpy than the return air and is below the set point, the

EconoMiSerIV opens to bring in outdoor air for free cooling.

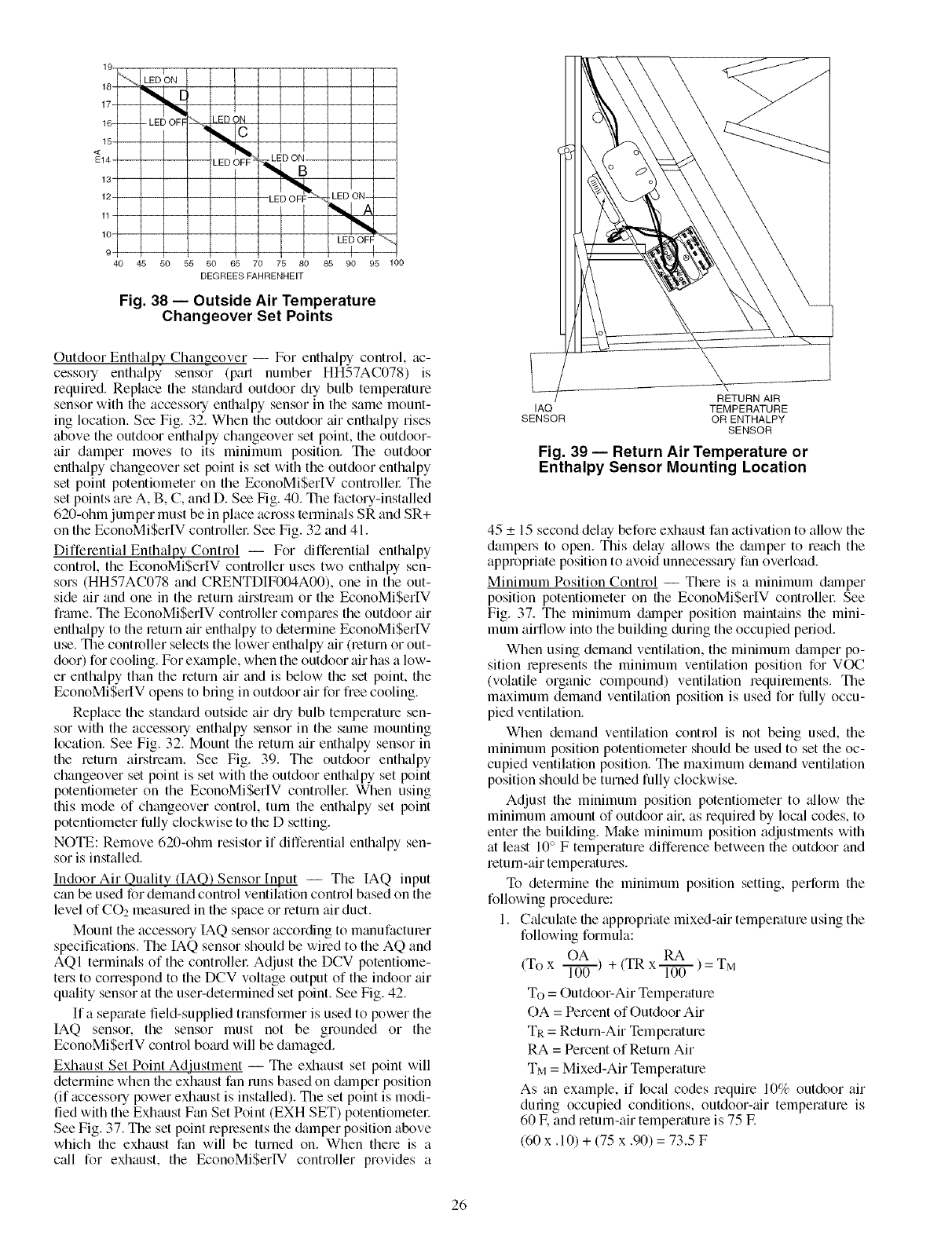

Replace the standard outside air ch_ bulb temperature sen-

sor with the accessory enth_dpy sensor in the same mounting

location. See Fig. 32. Mount the return air enthalpy sensor in

the return airstream. See Fig. 39. The outdoor enthalpy

changeover set point is set with the outdoor enth_flpy set point

potentiometer on the EconoMiSerIV controllel: When using

this mode of changeover control, turn the enth_flpy set point

potentiometer fiJlly clockwise to the O setting.

NOTE: Remove 620-ohm resistor if differential enthalpy sen-

sor is installed.

Indoor Air Quality (IAQ) Sensor [nput -- The IAQ input

can be used for demand control ventilation control based on the

level of CO2 measured in the space or return air duct.

Mount the accessory IAQ sensor according to manufacturer

specifications. The IAQ sensor should be wired to the AQ and

AQI terminals of the controllel: Adjust the DCV potentiome-

ters to correspond to the DCV voltage output of the indoor tfir

quality sensor at the user-determined set point. See Fig. 42.

If a sepmate field-supplied transformer is used to power the

IAQ sensor, the sensor must not be grounded or the

EconoMiSerlV control bomd will be damaged.

Exhaust Set Point Adjustment -- The exhaust set point will

determine when the exhaust fan runs based on dmnper position

(if accessory power exhaust is installed). The set point is modi-

fied with the Exhaust Fan Set Point (EXH SET) potentiometel:

See Fig. 37. The set point represents the cktmper position above

which the exhaust fan will be turned on. When there is a

c_dl for exhaust, the EconoMiSerIV controller provides a

RETURN AIR

IAQ TEMPERATURE

SENSOR OR ENTHALPY

SENSOR

Fig. 39 -- Return Air Temperature or

Enthalpy Sensor Mounting Location

45 _+15 second delay before exhaust fan actiw_tion to allow the

dampers to open. This delay _fllows the damper to reach the

appropriate position to avoid unnecessary fan overload.

Minimum Position Control -- There is a minimum damper

position potentiometer on the EconoMi$erIV controllel: See

Fig. 37. The minimum dmnper position mainttfins the mini-

mum airflow into the building during the occupied period.

When using demand ventilation, the minimum &tmper po-

sition represents the minimum ventilation position for VOC

(volatile organic compound) ventilation requirements. The

maximum demand ventilation position is used for fully occu-

pied ventilation.

When demand ventilation control is not being used, the

minimum position potentiometer should be used to set the oc-

cupied ventilation position. The maximum demand ventilation

position should be turned fully clockwise.

Adjust the minimum position potentiometer to _fllow the

minimum amount of outdoor air. as required by local codes, to

enter the building. Make minimum position adjustments with

at least 10° F temperature difference between the outdoor and

return-air temperatures.

To determine the minimum position setting, perform the

following procedure:

1. Calculate the appropriate mixed-air temperature using the

following formula:

OA + (TR RA

(To x l-T-if(]-) x _ ) = TM

To = Outdoor-Air Temperature

OA = Percent of Outdoor Air

TR = Return-Air Temperature

RA = Percent of Return Air

TM = Mixed-Air Temperature

As an example, if local codes require 10% outdoor air

during occupied conditions, outdoor-_fir temperature is

60 IF.and return-air temperature is 75 IF.

(60 x. 10) + (75 x .90) = 73.5 F

26