CONDENSER COiL ,

SUCTION

l DISCHARGE

F CCH

CRANKCASE

HEATER

OUTDOOR AiR

EVAPORATOR

COIL

S-LPS J

SUB COOLERCONTROL

LOW PRESSURESWITCH

TXV

SUBCOOLER /

COIL

EQUALIZER

LINE

INDOOR AIR

3-WAY

VALVE

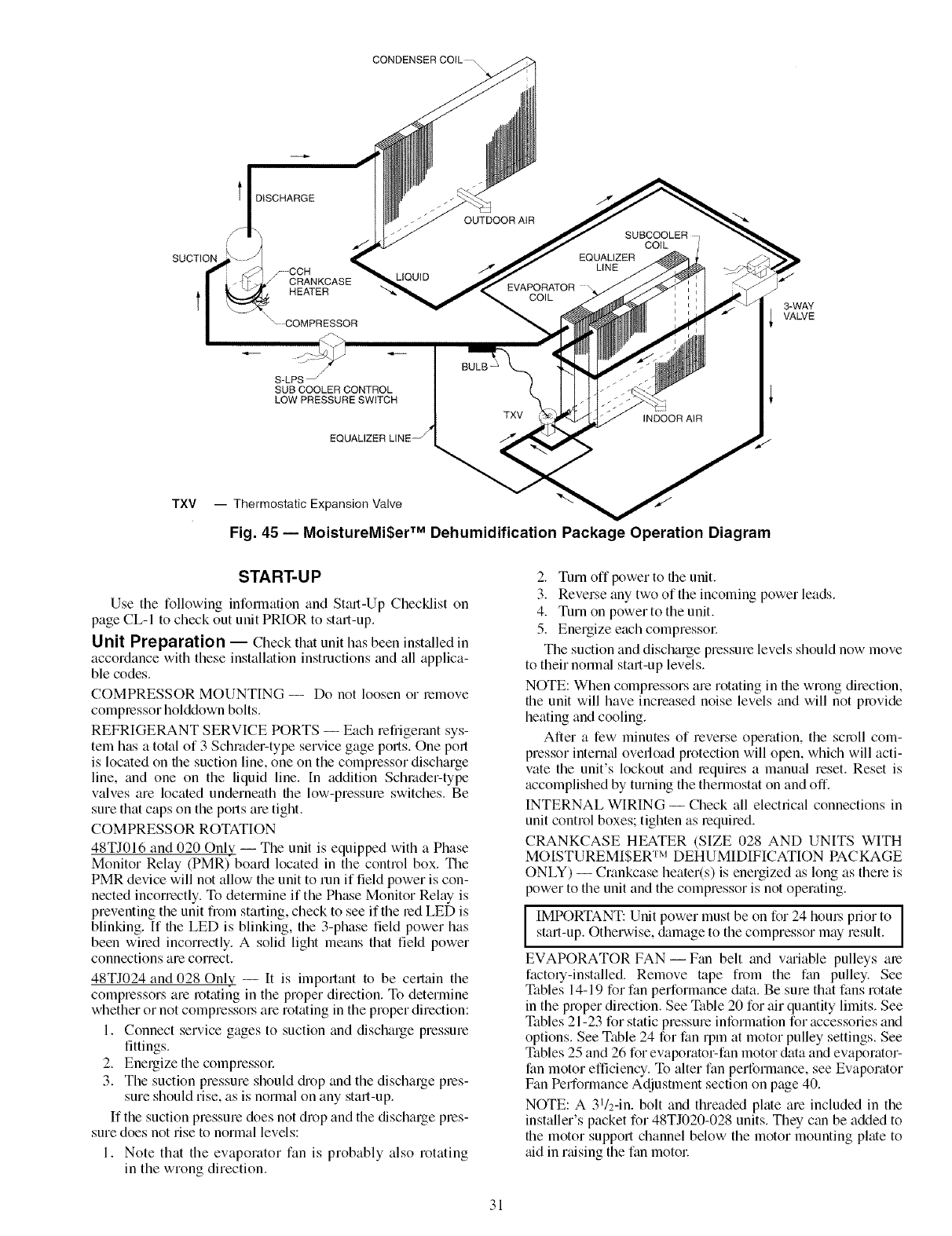

TXV -- Thermostatic Expansion Valve

Fig. 45 -- MoistureMi$er TM Dehumidification Package Operation Diagram

START-UP

Use the following information and Start-Up Checklist on

page CL-I to check out unit PRIOR to start-up.

Unit Preparation -- Check that unit has been installed in

accordance with these installation instructions and all applica-

ble codes.

COMPRESSOR MOUNTING -- Do not loosen or remove

complessor holddown bolts.

REFRIGERANT SERVICE PORTS -- Each reh'igerant sys-

tem has a total of 3 Schrader-type service gage ports. One port

is located on the suction line, one on the compressor discharge

line, and one on the liquid line. In addition Schmder-type

valves are located underneath the low-pressme switches. Be

sure that caps on the polls are tight.

COMPRESSOR ROTATION

48TJ016 and 020 Only -- The unit is equipped with a Phase

Monitor Relay (PMR) board located in the control box. The

PMR device will not allow the unit to run if field power is con-

nected incorrectly. To determine if the Phase Monitor Relay is

preventing the unit from starting, check to see if the red LED is

blinking, ff the LED is blinking, the 3-phase field power has

been wiled incorrectly. A solid light means that field power

connections are correct.

48TJ024 and 028 Only -- It is important to be certain the

compressors are rotaing in the proper direction. To determine

whether or not compressoB are rotaing in the proper direction:

I. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressoc

3. The suction pressure should &op and the discharge pres-

sure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres-

sure does not rise to normal levels:

1. Note that the evaporator fan is probably also rotating

in the wrong direction.

2. Turn off power to the unit.

3. Reverse any two of the incoming power leads.

4. Turn on power to the unit.

5. Energize each compressoc

The suction and discharge pressure levels should now move

to their normtd start-up levels.

NOTE: When compressors are rotating in the wrong direction,

the unit will have increased noise levels and will not provide

heating and cooling.

After a few minutes of reverse operation, the scroll com-

pressor intermfl overload protection will open, which will acti-

vate the unit's lockout and requires a manual reset. Reset is

accomplished by turning the thermostat on and off.

INTERNAL WIRING -- Check all electrical connections in

unit control boxes; tighten as required.

CRANKCASE HEATER (SIZE 028 AND UNITS WITH

MOISTUREMI$ER TM DEHUMIDIFICATION PACKAGE

ONLY) -- Crankcase heater(s) is energized as long as there is

power to the unit and the compressor is not operating.

I MPORTANT: Unit power must be on for 24 houB prior to Istart-up. Otherwise, &mmge to the compressor may result.

I

EVAPORATOR FAN- Fan belt and vmiable pulleys are

factory-installed. Remove tape from the fan pulley. See

Tables 14-19 for fan performance data. Be sure that fans rotate

in the proper direction. See Table 20 for air quantity limits. See

Tables 21-23 for static pressure information for accessories and

options. See Table 24 for fan rpm tit motor pulley settings. See

Tables 25 and 26 for evaporator-fan motor data and evaporator-

fan motor efficiency. To alter fan performance, see Evaporator

Fan Perforlnance Adjustment section on page 40.

NOTE: A 31/2-in. bolt and threaded plate are included in the

installer's packet for 48TJ020-028 units. They can be added to

the motor support channel below the motor mounting plate to

aid in raising the fan motor

31