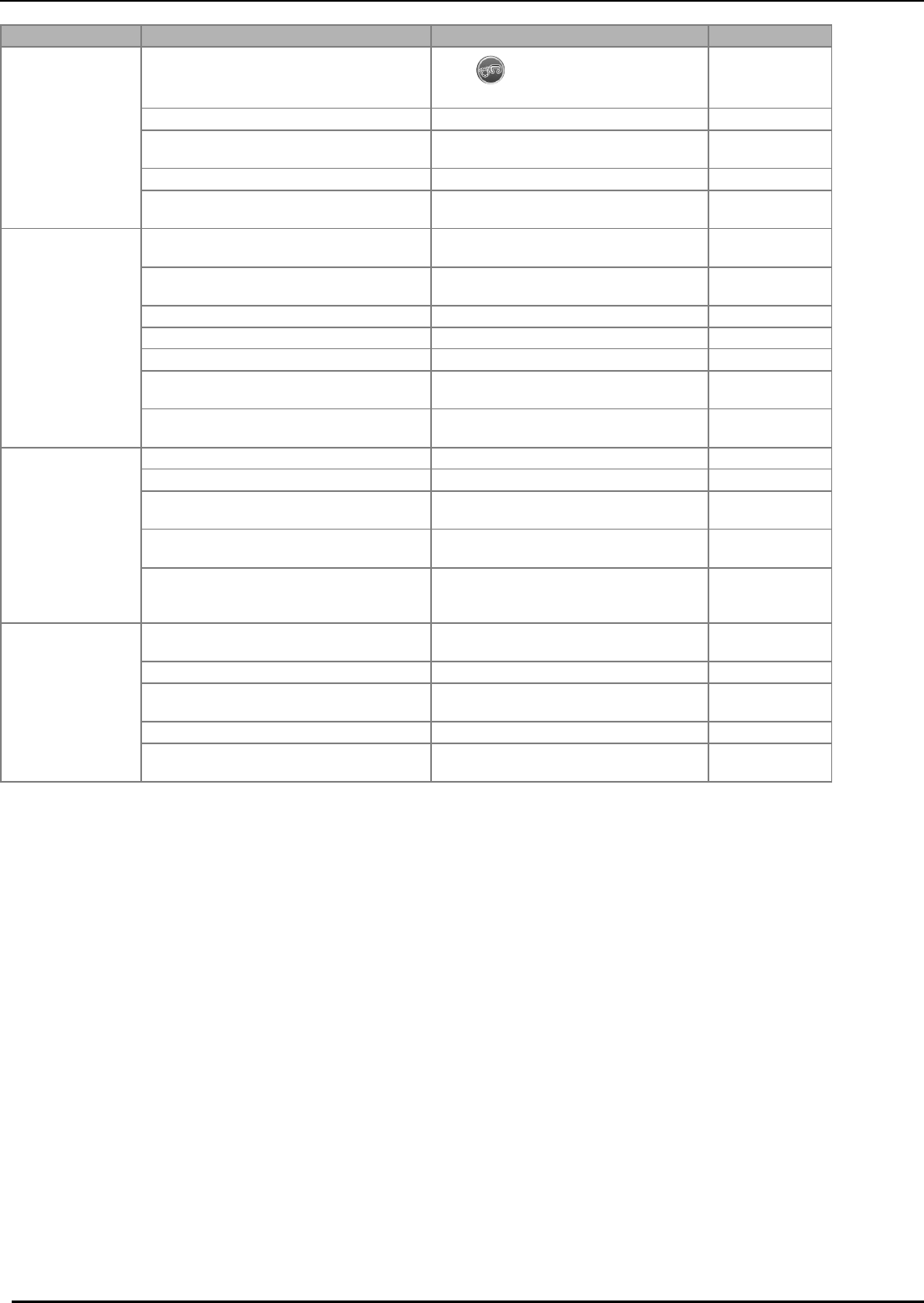

TROUBLESHOOTING

332

Fabric does not feed

through the machine

Feed dogs are set in the down position.

Press , and then turn the handwheel to

raise the feed dogs.

105

Stitches are too close together. Lengthen the stitch length setting. 67

Wrong presser foot was used. Use the correct presser foot.

“STITCH SETTING

CHART”

Needle is turned, bent or the point is dull. Replace the needle. 56

Thread is entangled. Cut the entangled thread and remove it from

the race.

—

Fabric puckers There is a mistake in the upper or bobbin

threading.

Check the steps for threading the machine

and rethread it correctly.

43, 46

Using improper needle or thread for the

selected fabric.

Check the “Fabric/Thread/Needle

Combination” chart.

58

Thread tension is set incorrectly. Adjust the thread tension. 67, 227

Stitches are too long when sewing thin fabrics. Shorten the stitch length. 67

Needle is turned, bent or the point is dull. Replace the needle. 56

Spool cap is set incorrectly. Check the method for attaching the spool cap,

then reattach the spool cap.

46

Wrong presser foot. Use the correct presser foot. “STITCH SETTING

CHART”

High-pitched sound

while sewing

Dust or lint is caught in the feed dogs. Remove the dust or lint. 326

Pieces of thread are caught in the race. Clean the race. 326

Upper threading is incorrect. Check the steps for threading the machine

and rethread the machine.

46

There are scratches on the race. Replace the race, or consult your authorized

dealer.

326

A bobbin designed specifically for this machine

is not used.

Incorrect bobbins will not work properly. Only

use a bobbin designed specifically for this

machine.

43

Character pattern

does not turn out

Wrong presser foot was used. Attach the correct presser foot. “STITCH SETTING

CHART”

Pattern adjustment settings were set incorrectly. Revise the pattern adjustment settings. 153

Did not use a stabilizer material on thin fabrics

or stretch fabrics.

Attach a stabilizer material. 152

Thread tension is set incorrectly. Adjust the thread tension. 67, 227

Fabric was pulled, pushed or fed at an angle

while it was being sewn.

Sew while guiding the fabric with your hands

so that the fabric is fed in a straight line.

60

Problem Cause Solution Page