User Connections 29

4

User Connections

Rear Panel Connections

Make application load connections to the output terminals or bus bars, analog connector, and digital connector as shown on

the rear-panel drawing for your model Agilent SAS. Make controller connections (GPIB and serial link) as shown in Figure

4-12 at the end of this chapter.

Wire Selection

Fire Hazard To satisfy safety requirements, load wires must be large enough not to overheat when

carrying the maximum short-circuit current of the Agilent SAS. If there is more than one load, then any

pair of load wires must be capable of safely carrying the full-rated current of the unit.

Table 4-1 lists the characteristics of AWG (American Wire Gauge) copper wire.

Table 4-1. Wire Characteristics

AWG No. Ampacity (in free air) Resistance (at 20 deg. C)

Ω/m Ω/ft

20 8.33 0.0345 0.01054

18 15.4 0.0217 0.00663

16 19.4 0.0137 0.00417

14 31.2 0.0086 0.00262

12 40 0.0054 0.00165

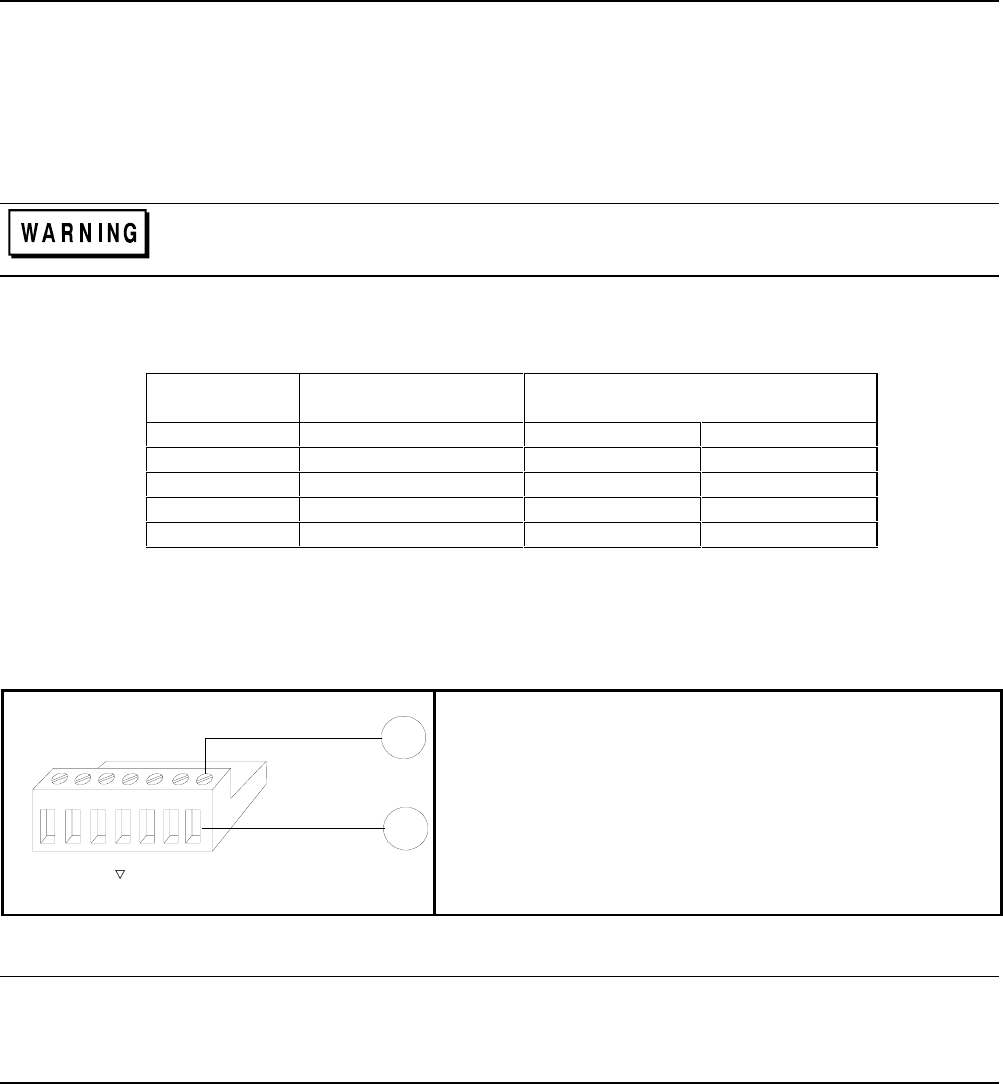

Analog Connector

This connector, which is on the rear panel, is for connecting remote sense leads, external current monitors, and external

current programming sources. The connector accepts wires sizes from AWG 22 to AWG 12.

1

IM

IP

IP

S

S

-

+-

+

-

-

I

SAS

P

2

Insert Wires

k Tighten screws

+IP Differential current programming input (positive).

−

IP Differential current programming input (negative).

−

SAS Auto-parallel output connection (SAS mode only).

Ps Common output for -IM and -SAS signals.

−

IM Current monitor output (referenced to Ps).

+ S remote sense input (positive).

−S remote sense input (negative).

Figure 4-1. Rear Panel Analog Connector

Note It is good engineering practice to twist or shield all signal wires to and from the analog and digital

connectors.

To minimize spurious operation, make sure that all analog wiring except for the + and − sense wires does

not exceed 3 meters in length.