SCXG-SVX01B-EN 97

Owner

Sequence of

Operation

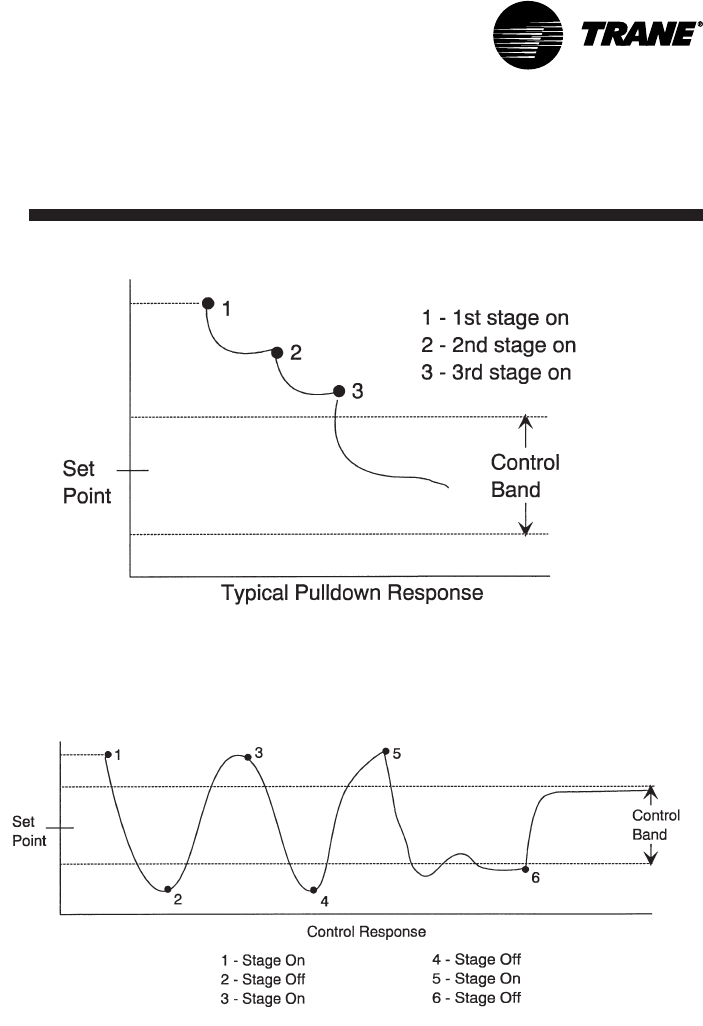

Figure O-SO-2. Typical pulldown curve for unit operating properly within control band.

Figure O-SO-3. Typical pulldown curve for unit operating improperly outside control band.

band according to the desired unit

performance. Increasing the control band

reduces the equipment cycle rate and

increases the maximum potential supply

air temperature deviation from setpoint.

Conversely, decreasing the control band

reduces the maximum potential tem-

perature deviation, but increases the

compressor cycle rate.

Follow these recommendations concern-

ing the supply air temperature control

band settings based on expected unit

sizing:

2 Cooling stage unit: 9 F

3 Cooling stage unit: 7 F

4 Cooling stage unit: 6 F

Low Ambient Compressor Lockout

This function will lock out the compressor

if the outdoor air temperature sensor

reads an outdoor temperature below the

low ambient compressor lockout

temperature setpoint. This setpoint is

adjustable at the human interface panel.

Compressors will lock out when outdoor

air temperature falls below that selected

temperature and will start again when

the temperature rises 5 F above the

setpoint.

Evaporator Coil Frost Protection

FROSTAT

™

The FROSTAT

™

system eliminates the

need for hot gas bypass. It utilizes an

evaporator temperature sensor mounted

on the suction line near the TXV bulb of

each circuit to protect the evaporator

from freezing.

If the evaporator temperature ap-

proaches the specified setpoint (adjust-

able between 25 and 35 F at the HI) the

compressor(s) will cycle off. The supply

fan remains on to help de-ice the coil. The

compressors will restart when the

evaporator temperature has risen 10 F

above the specified cutout temperature

and when the compressor(s) have been

off a minimum of three minutes. This

prevents rapid cycling of the compres-

sors.

Service Valves

Service valves are factory installed on

each circuit before and after the

compressor to allow compressor

isolation for servicing.