100 SCXG-SVX01B-EN

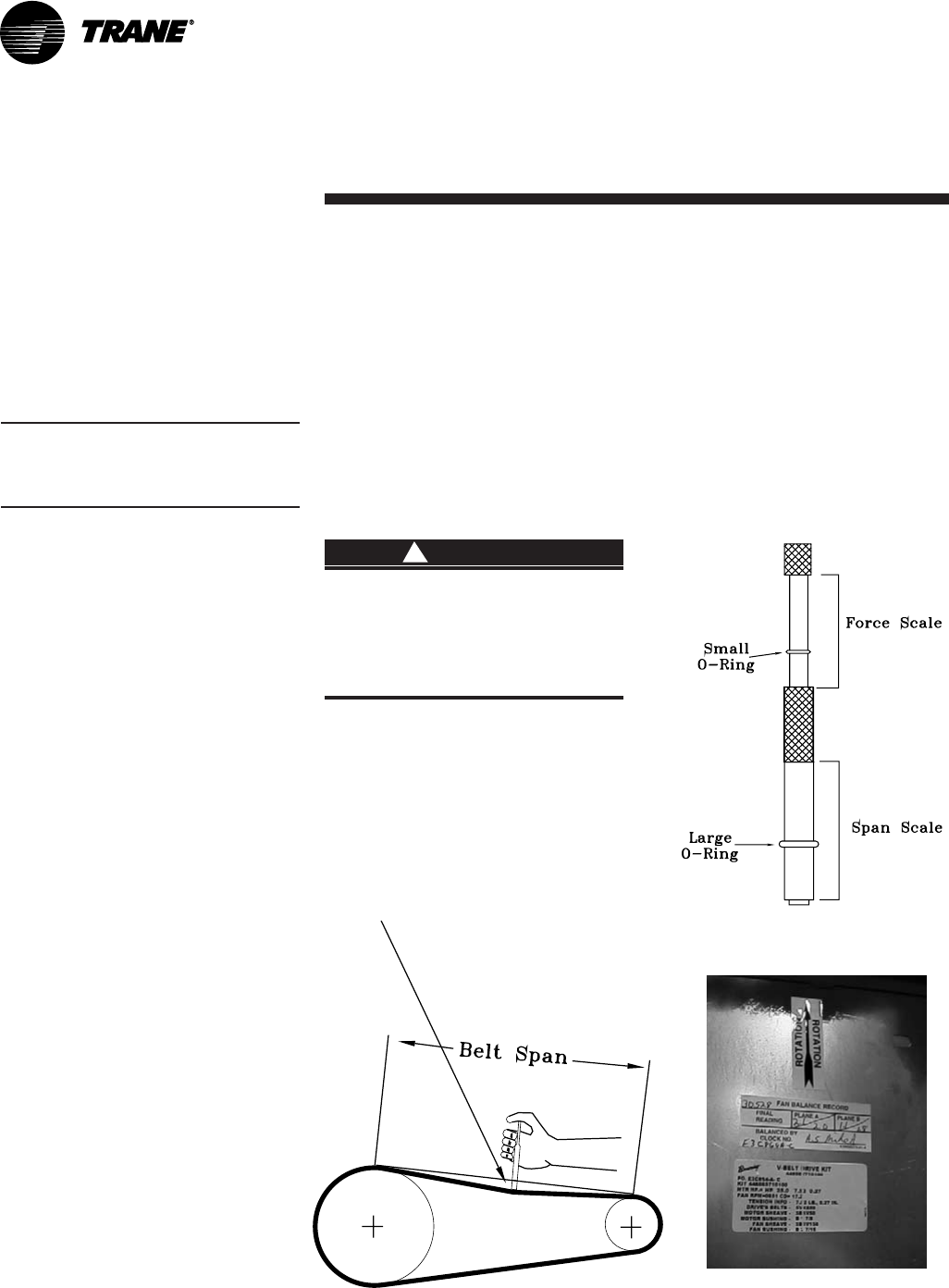

Figure O-M-2. Fan Belt Adjustment.

Figure O-M-3. Belt Tension Gauge.

Fan Bearings

The opposite drive end bearing is a

special bearing with close tolerance fit of

balls and races. Replace this bearing with

the same part number as the original

bearing.

Fan Belt Tension

Note: Check fan belt tension at least twice

during the first days of new belt operation

since there is a rapid decrease in tension

until belts are run-in.

Proper belt tension is necessary to

endure maximum bearing and drive

component life and is based on fan brake

horsepower requirements. If frayed or

worn, replace belts in matched sets.

Measuring Belt Tension

Measure fan belt tension with a

Browning, Gates, or equivalent belt

tension gauge. Determine deflection by

dividing the belt span distance (in inches)

by 64. See Figure O-M-2.

Recommended belt tension range values

are on the unit fan scroll. The belt tension

label is on the top right-hand corner of the

fan scroll. See Figure O-M-4.

Follow the procedure below to measure

belt tension.

1. Measure belt span between centers of

sheaves and set the large “O” ring of

the tension gauge at

1

/

64

inch for each

inch of belt span.

2. Set the load “O” ring at zero.

3. Place the large end of the gauge at the

center of the belt span. Press down until

the large “O” ring is even with the top

of the belt line or the next belt as in

Figure O-M-2. Place a straight edge

across the sheaves as a reference

point. See Figure O-M-1 on page 99.

4. Remove the gauge. Note that the load

“O” ring now indicates a number on the

plunger scale. This number represents

pounds of force required to deflect the

belt.

5. Check the reading from step 4 against

the values given on the unit fan scroll. If

necessary, readjust belt tension.

Deflection = Belt Span/64

Owner

Maintenance

Adjusting Belt Tension

To adjust belt tension refer to Figure O-M-

2 and perform the following procedure:

1. Loosen bolts A, B, and E on both sides

of the sliding motor base. See Figure O-

M-4.

2. Loosen nuts C and D (as required for

motor horsepower) to slide the motor

on its mounting plate in the proper

direction to tension or relieve tension on

the belt.

3. Adjust nuts A-D and bolt E. Do not

stretch the belts over the sheaves.

4. Retighten all nuts and bolts.

5. Verify tension is adjusted properly.

Do not over-tension the belts.

Excessive tension will reduce fan

and motor bearing life, accelerate

belt wear, and possibly cause

shaft failure.

Figure O-M-4. Location of fan belt label on

fan scroll.

CAUTION

!

Recommended belt tension range values

are on the unit fan scroll. To access the

fan scroll, face the right-hand side of the

unit and remove the top left panel. The

belt tension label is on the top right-hand

corner of the fan scroll. See Figures O-M-

4.

The correct operation tension for a V-belt

drive is the lowest tension at which the

belt will not slip under the peak load

conditions. It may be necessary to

increase the tension of some drives to

reduce flopping or excessive start-up

squealing.