SCXG-SVX01B-EN 95

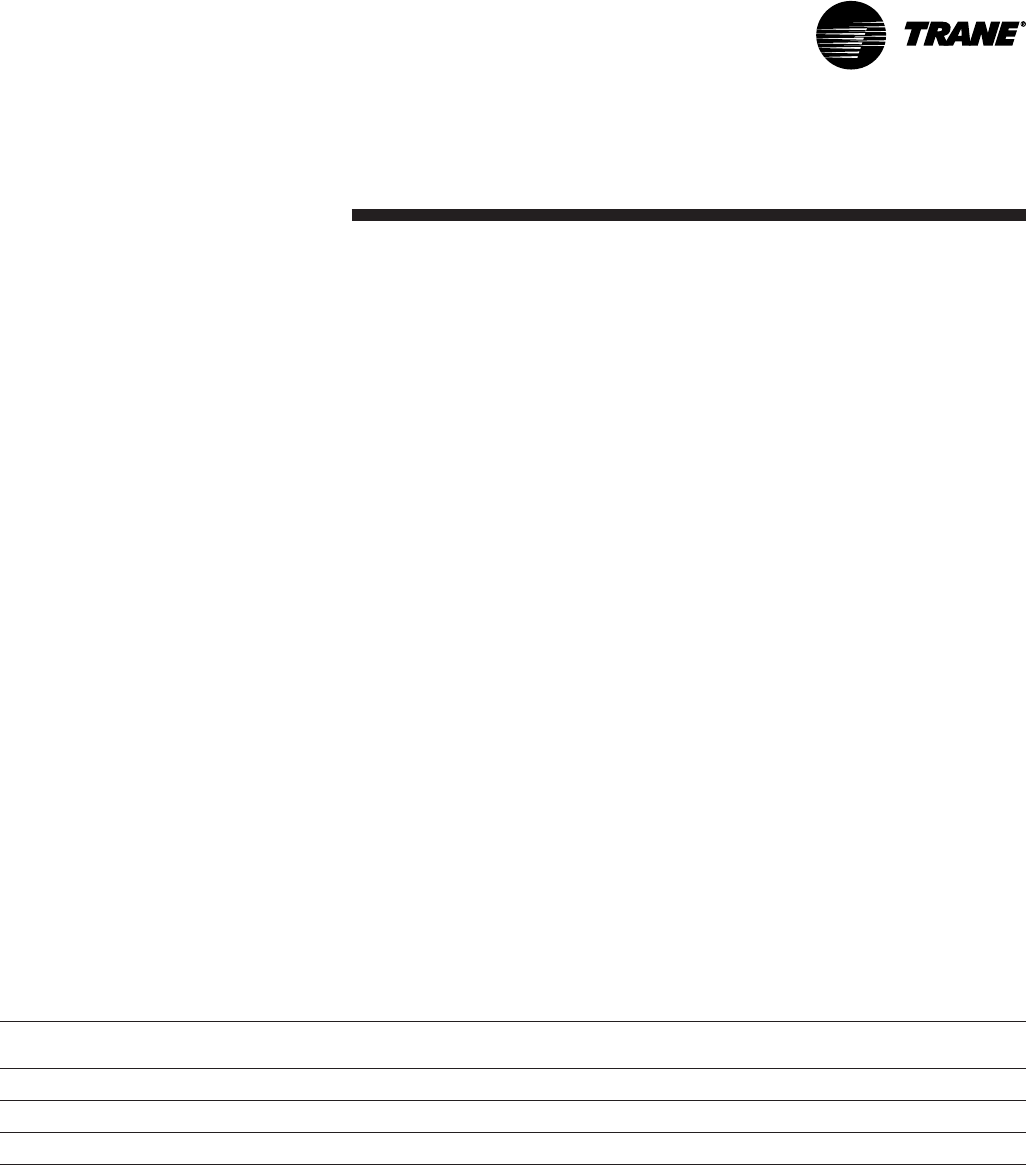

Table O-SO-1. Compressor Stages.

Unit Refrigerant Compressor HP Standard Lead/Lag SCM

Size Circuit Type by Stage Compressor Compressor or

Model # Digit 5 A B Staging Staging MC

SXWG 20, 25 Independent 10 10 B/AB A/AB MCM

SXRG 20

SXWG 30 Independent 15 10 B/A/AB A/AB MCM

SXRG 25

SXWG 35 Independent 15 15 B/AB A/AB MCM

SXRG 32

Owner

Compressors

Units use two sizes of hermetic scroll

compressors, 10 and 15 hp, and can use

from two to four compressors. When

viewing the front of the unit, compressors

are identified A through B from left to

right. The second compressor from the

left, or B compressor, is always the first to

come on, unless locked out for a

malfunction or shut off on frost protection.

Refer to Table O-SO-1 for compressor

cycling stages and Table O-SO-3 on page

96 for percent cooling capacity by stage.

The control system logic permits com-

pressor operation only after the supply

fan is on. If the supply fan shuts down,

compressors will not operate. Units

without head pressure control (units with

intermediate piping packages) will lock

out mechanical cooling when the entering

condenser water temperature falls below

54 F. Mechanical cooling will resume

when the entering condenser water

temperature exceeds 58 F.

Sequence of

Operation

Compressor Cycling

Compressors cycle to maintain the

operating state required by the

temperature controls. In the event of a

compressor failure, the next available

compressor turns on. Refer to Table O-

SO-1 for compressor cycling by unit

model and tons.

During normal conditions, compressors

will not shut off until they have been on

for at least three minutes and will not turn

on until they have been off for at least

three minutes. Normal operating condi-

tions are established on an individual

compressor basis. When a compressor

starts, its timer also starts. The compres-

sor evaporator circuit frost protection can

override the “minimum” timer and

reduce the five minute minimum re-

quired time period.

When the unit is powered up, or manually

reset there will be a three to eight minute

delay before the first compressor may be

turned on as requested by the unit

temperature control algorithm.

Compressor Lead/Lag Operation

Compressor lead/lag is a user-selectable

feature at the HI panel and is available on

all units. After each request for

compressor operation, the lead

refrigeration circuit or compressor

switches, thereby causing a more

equitable or balanced run time among

compressors.

When lead/lag is enabled, each time the

system cycles, it will alternate between

the standard compressor staging and the

lead/lag staging. Using Table O-SO-1, a

SXWG 30-ton unit will first stage com-

pressor B then A, then AB for first cycle

and A, then AB for the second cycle.

Appropriate condenser valves (water-

cooled and condenser fans (air-cooled)

will stage with appropriate compressors

to maintain saturated condensing

temperature. Enabling lead/lag may drop

a cooling stage when compared to

standard staging. See Table O-SO-1 for

compressor staging.