SCXG-SVX01B-EN 81

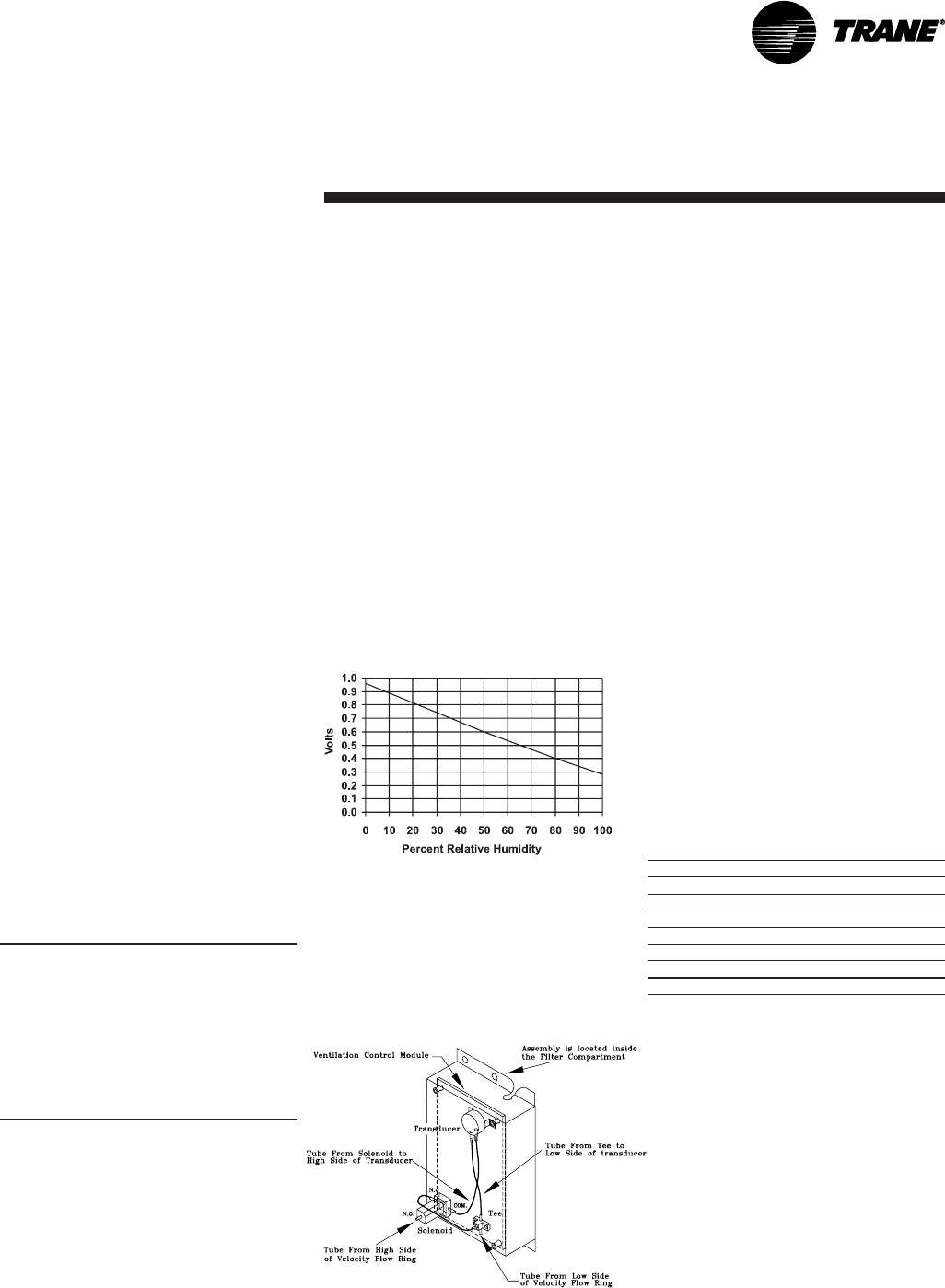

Figure O-GI-2. Velocity Pressure Trans-

ducer/Solenoid Assembly.

• VO relay – energized

• Exhaust fan (field-installed) - on

• Exhaust damper (field-installed) - open

PURGE sequence “D”

This sequence could be used for purging

the air out of a building before coming out

of unoccupied mode of operation on VAV

units. Also, it can be used to purge smoke

or stale air.

• Supply fan – on

• Supply fan VFD – on (60 Hz)

(if equipped)

• Inlet guide vanes/VAV boxes – Open

(if equipped)

• Outside air damper – Open

• Heat – all stages – Off, Modulating heat

output at 0 vdc

• Occupied/unoccupied output – Energized

• VO relay – Energized

• Exhaust fan (field-installed) - On

• Exhaust damper (field-installed) - Open

PURGE with duct pressure control “E”

This sequence can be used when supply

air control is required for smoke control.

• Supply fan – on

• Supply fan VFD – on (if equipped)

• Inlet guide vanes – controlled by supply

air pressure control function with

supply air pressure high limit disabled

• Outside air dampers – open

• Heat – all stages – off, hydronic heat

output at 0 vdc

• Occupied/unoccupied output – energized

• VO relay – energized

• Exhaust fan (field-installed) - on

• Exhaust damper (field-installed) - open

Note: Each system (cooling, exhaust,

supply air, etc.) within the unit can be

redefined in the field for each of the five

sequences, if required. Also the definitions

of any or all of the five sequences may be

locked into the software by simple key

strokes at the human interface panel. Once

locked into the software, the sequences

cannot be changed.

Trane Communications

Interface Module (TCI) - Option

used with Trane ICS

TM

The Trane communication interface

module allows external setpoints for

most of the unit functions to be

communicated to the unit's UCM network

via a Trane ICS

TM

systems. DIP switch

settings on the TCI module for this

Owner

General

Information

application are; switch 1 “off,” 2 “on,” and

3 “off.”

Exhaust/Comparative

Enthalpy Module (ECEM) - On

Units with Comparative

Enthalpy Option

The exhaust/comparative enthalpy

module receives information from the

return air humidity sensor, and the RTM

outside air temperature sensor and

outside air humidity sensor, the outside

air humidity sensor and temperature

sensor to utilize the lowest possible

enthalpy level when considering

economizer operation. In addition, it

receives space pressure information to

maintain the space pressure within the

setpoint control band. Refer to the Figure

O-GI-1 for humidity vs. voltage values.

Ventilation Control Module

(VCM) - Available only with

Tra q ™ Damper Option

The ventilation control module (VCM) is

located in the airside economizer section

of the unit and linked to the unit’s UCM

network. Using a velocity pressure

transducer/solenoid (pressure sensing

ring) in the fresh air section allows the

VCM to monitor and control fresh air

entering the unit to a minimum airflow

setpoint. See Figure O-GI-2 for a detail

view of the velocity pressure transducer/

solenoid assembly.

An optional temperature sensor can be

connected to the VCM to enable control

of a field installed fresh air preheater.

Also, a field-provided CO

2

sensor can be

connected to the VCM to control CO

2

reset. The reset function adjusts the

minimum cfm upward as the CO

2

concentrations increase. The maximum

effective (reset) setpoint value for fresh

air entering the unit is limited to the

system’s operating cfm. Table O-GI-5 lists

the minimum outside air cfm vs. input

voltage.

Table O-GI-5. Minimum Outside Air

Setpoint w/VCM Module and Traq™

Sensing.

Unit Input Volts CFM

SXWG 20 0.5 - 4.5 vdc 6,350-8,500

SXWG 25 0.5 - 4.5 vdc 7,250-10,625

SXWG 30 0.5 - 4.5 vdc 7,250-12,750

SXWG 35 0.5 - 4.5 vdc 7,250-14,875

SXRG 20 0.5 - 4.5 vdc 7,250-8,500

SXRG 25 0.5 - 4.5 vdc 7,250-10,625

SXRG 32 0.5 - 4.5 vdc 7,250-13,600

Figure O-GI-1. ECEM Relative Humidity vs.

Voltage.