Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 40

FOR SERVICE OR REPAIR, FOLLOW THESE STEPS IN ORDER:

FIRST: Contact the Installer

Name __________________________________________________________

Address_________________________________________________________

__________________________________________________________

__________________________________________________________

Phone _____________________________________

SECOND: Contact the nearest distributor (See Yellow Pages). If no listing,

contact Authorized Factory Representative, 1-800-695-1901 (Press 1).

THIRD: Contact REZNOR

®

/ Thomas & Betts Corporation

150 McKinley Avenue

Mercer, PA 16137

Phone: (724) 662-4400

Model No. _________________________________

Heater Serial No._____________________________

Date of Installation ___________________________

(800) 695-1901; www.RezSpec.com

©2005 Thomas & Betts Corporation, All rights reserved.

MANUFACTURER OF HEATING, COOLING, AND VENTILATING SYSTEMS

Trademark Note: Reznor

®

and TCORE

2®

are trademarks of Thomas & Betts.

9/05 Form RZ-NA I-LDAP (Version .2)

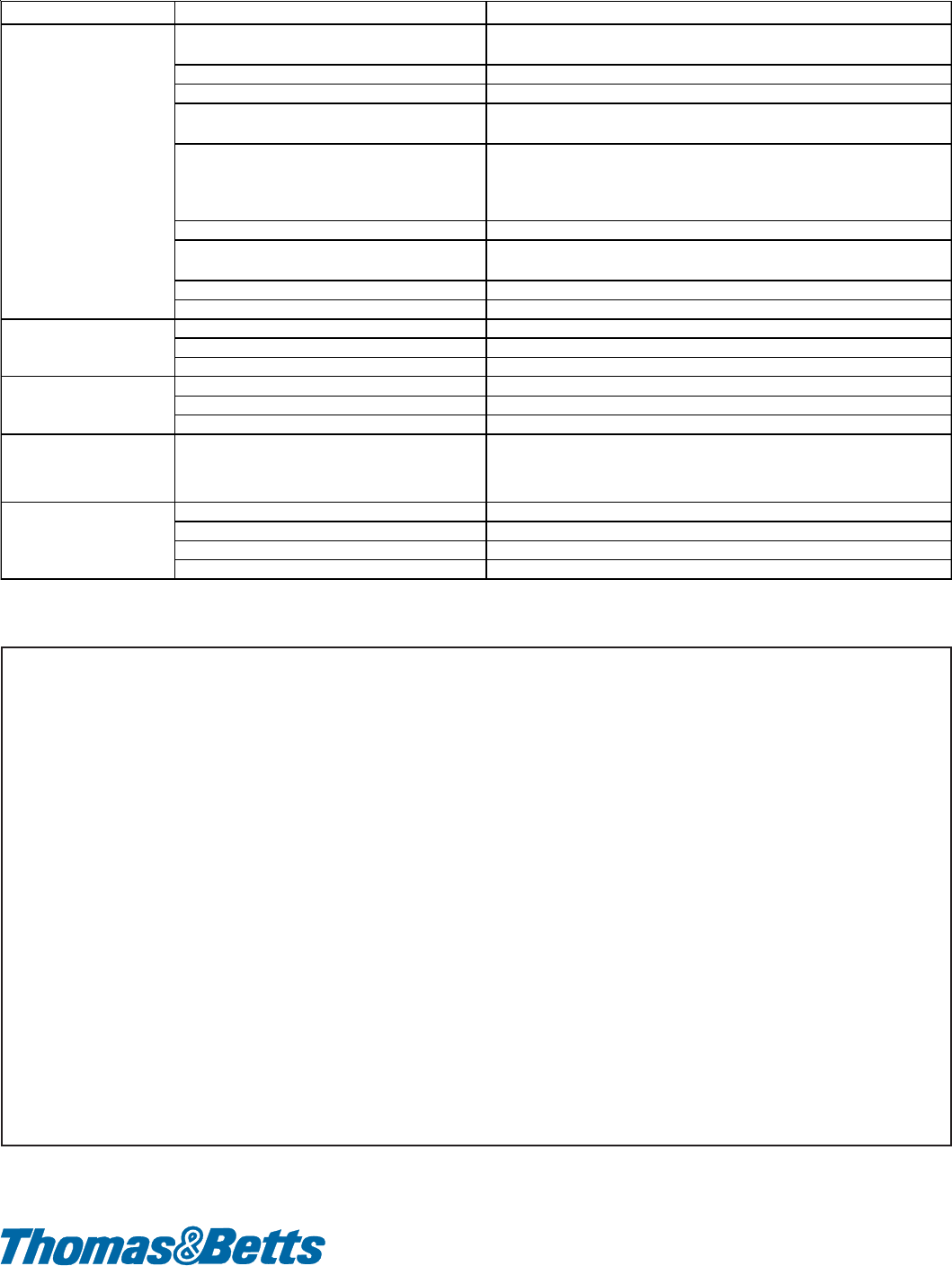

General Troubleshooting (cont’d)

PROBLEM (cont'd) PROBABLE CAUSE (cont'd) REMEDY (cont'd)

1. Gas pressure too high or too low. 1. Supply pressure should be 5" - 14" w.c. for natural gas or 11" - 14"

w.c. for propane gas.

2. Burner not

g

rounded 2. Make certain inte

g

rated circuit board is

g

rounded to i

g

nitor.

3. Circuit board not

g

rounded. 3. Make certain inte

g

rated circuit board is

g

rounded to furnace chassis.

4. Faulty integrated circuit board 4. If 24 volt is available to the integrated circuit board and all other

causes have been eliminated, replace board.

5.

a

)

Make sure unit is

p

ro

p

erl

y

vented.

b)

Remove obstructions from vent.

c

)

Re

p

lace fault

y

tubin

g

to

p

ressure switch.

6. Fault

y

combustion air

p

rovin

g

switch. 6. Re

p

lace combustion air

p

rovin

g

switch.

7. Flame sensor grounded. 7. Be certain flame sensor lead is not grounded or insulation or ceramic

is not cracked. Replace as required.

8. Cracked ceramic at sensor. 8. Re

p

lace sensor.

9. Incorrect

p

olarit

y

. 9. Reverse line volt leads to inte

g

rated circuit board.

1. Incorrect valve outlet

p

ressure or orifice. 1. Check valve outlet

p

ressure. See Ratin

g

p

late for manifold

p

ressure.

2. C

y

clin

g

on limit control. 2. Check air throu

g

h

p

ut.

3. Im

p

ro

p

er thermostat location or ad

j

ustment. 3. See thermostat manufacturer's instructions.

1. Circuit o

p

en. 1. Check wirin

g

and connections.

2. Defective inte

g

rated circuit board. 2. Re

p

lace board.

3. Defective motor. 3. Re

p

lace motor.

Fan or venter motor turns

on and off while burner is

operating

1. Motor overload device cycling on and off. 1. Check motor load against motor rating plate. Replace motor if needed.

1. Low or hi

g

h volta

g

e su

pp

l

y

. 1. Correct electric su

pp

l

y

.

2. Defective motor. 2. Re

p

lace motor.

3. Poor airflow. 3. Clean motor, fan, fan

g

uard, filter, and coils.

4. Defective bearin

g

or lubrication. 4. Lubricate bearin

g

s

(

moto r

p

ermittin

g)

or re

p

lace motor.

Fan or venter motor will

not run

Fan or venter motor cuts

out on overload

Burner cycle on and off

5. Combustion air proving switch(es) not

closing.

No heat (Heater

Operating)