Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 27

3) Venter (Flue)

Outlet

Venter Outlet Attachment Requirements:

inches mm

400

6152

800

8203

1200

8203

Mode l

LDAP

Size

Venter Outlet

Diameter

Depending on the size of vent pipe

as determined in Step No. 2, attach

either the vent pipe directly to the

venter collar or a taper-type enlarger.

4) Joints and Sealing

Provide field-supplied vent pipe as specified in Requirement No. 1.

• If using single wall, 26-gauge or heavier galvanized pipe, secure slip-fit connec-

tions using sheetmetal screws or rivets. Seal pipe joints either with tape suitable for

550°F (such as Option FA1, P/N 98266) or high-temperature silicone sealant.

• If using Category III vent pipe, follow pipe manufacturer's instructions for join-

ing pipe sections. When attaching Category III pipe to the venter outlet or the vent

cap, make secure, sealed joints following a procedure that best suits the style of

Category III pipe being used.

• If installing a double-wall (Type B) terminal pipe, follow the instructions in FIG-

URE 17C to join the double-wall pipe to a single-wall or Category III vent pipe

run. To attach the vent cap, follow instructions in FIGURE 17B.

• If using double-wall (Type B) vent pipe in the vent pipe run (at least 75% of the

equivalent vent length must be vertical), follow the pipe manufacturer's instruc-

tions for joining pipe sections. For attaching double-wall pipe to the heater, see

FIGURE 17A. To attach the vent cap, see FIGURE 17B.

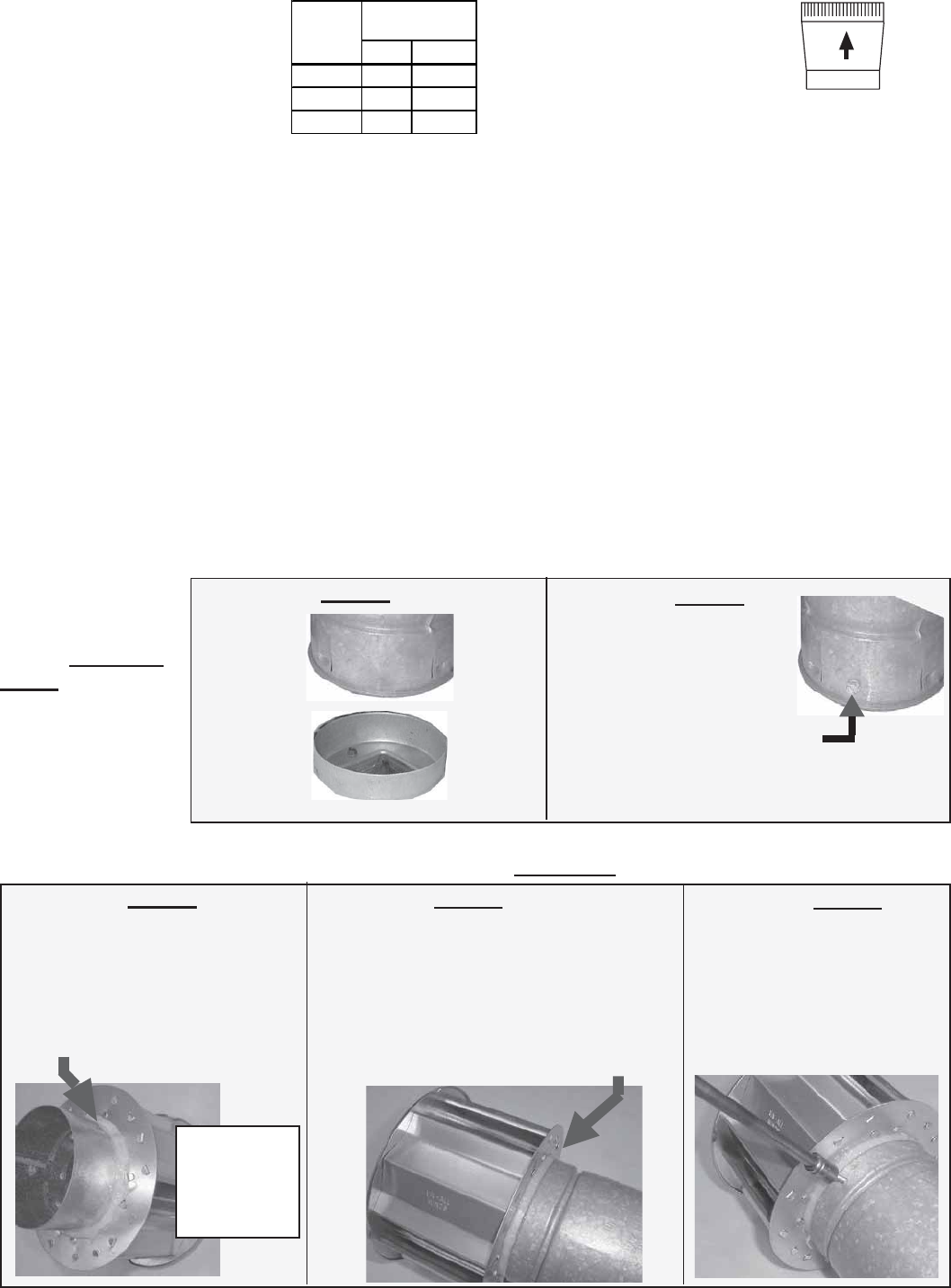

FIGURE 17A -

Attaching Double-

Wall (Type-B) Vent

Pipe to the Venter

Outlet

A double-wall pipe

run is allowed only if

at least 75% of the

vent length is vertical.

Figure 17A - STEP 1

To secure the connection,

spaced equal distance around

the pipe, drill and insert three

3/4” long sheetmetal screws

through the pipe and into the

collar. Do not over tighten the

screws.

Venter

Collar

Double-

Wall

Pipe

Slide the

double-wall

pipe over

the collar

so that the

collar is

inside the

inner pipe.

Figure 17A - STEP 2

Figure 17B - STEP 1

Place a continual 3/8” bead of

silicone sealant around the

circumference of the vent cap collar.

This will prevent any water inside

the vent cap from running down the

double-wall pipe.

Figure 17B - STEP 2

Secure the vent cap to the

double-wall pipe by drilling

and inserting a

3/4” long sheetmetal screw

into the vent cap collar. Do

not over tighten screw.

Insert the collar on the vent cap inside the

inner wall of the double-wall pipe. Insert as

far as possible. Add additional silicone sealant

to fully close any gaps between the vent cap

and the double-wall pipe. This is necessary to

prevent water from entering the double-wall

pipe.

Figure 17B - STEP 3

Do STEP 2

immediately

following

STEP 1.

FIGURE 17B - Attaching Double-Wall (Type B) Pipe to a Vent Cap

Taper-type

Pipe

Diameter

Increaser

Airflow

Follow instructions in Requirement No. 4. below to make

the connection for the type of pipe being used.

Fill inside the pipe, around the collar, with

silicone sealant being sure there are no gaps.