Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 11

Valve Outlet or

Orifice Pressure

Setting

Measuring valve outlet gas pressure cannot be done until the heater is in operation. It

is included in the steps of the "Check-Test-Start" procedure in Paragraph 25. The

following warnings and instructions apply. Model LDAP 400 has one gas valve;

Model LDAP 800 has two gas valves; and Model LDAP 1200 has three gas valves.

WARNING: Valve outlet

gas pressure must never

exceed 3.5" w.c. for

natural gas and 10" w.c.

for propane gas.

For Natural Gas: When the heater leaves the factory, the combination gas valve(s)

is set so that the valve outlet gas pressure for a single stage valve or high fire of a two

stage valve is regulated to 3.5" w.c. Low fire on a two-stage valve (Size 400 only) is

set to 1.8” w.c. Inlet supply pressure to the heater for natural gas must be a minimum

of 5" w.c. or as noted on the rating plate and a maximum of 14" w.c.

For Propane Gas: When the heater leaves the factory, the combination gas valve(s)

is set so that the valve outlet gas pressure for a single stage valve or high fire of a two

stage valve is regulated to 10" w.c. Low fire on a two-stage valve (Size 400 only) is

set to 5.0” w.c. Inlet supply pressure to the heater for propane gas must be a mini-

mum of 11" w.c. and a maximum of 14" w.c.

Before attempting to measure or adjust valve outlet gas pressure, the inlet

supply pressure must be within the specified range both when the heater is in opera-

tion and on standby. Incorrect inlet pressure could cause excessive valve outlet gas

pressure immediately or at some future time. If natural gas supply pressure is too

high, install a regulator in the supply line before it reaches the heater. If natural gas

supply pressure is too low, contact your gas supplier.

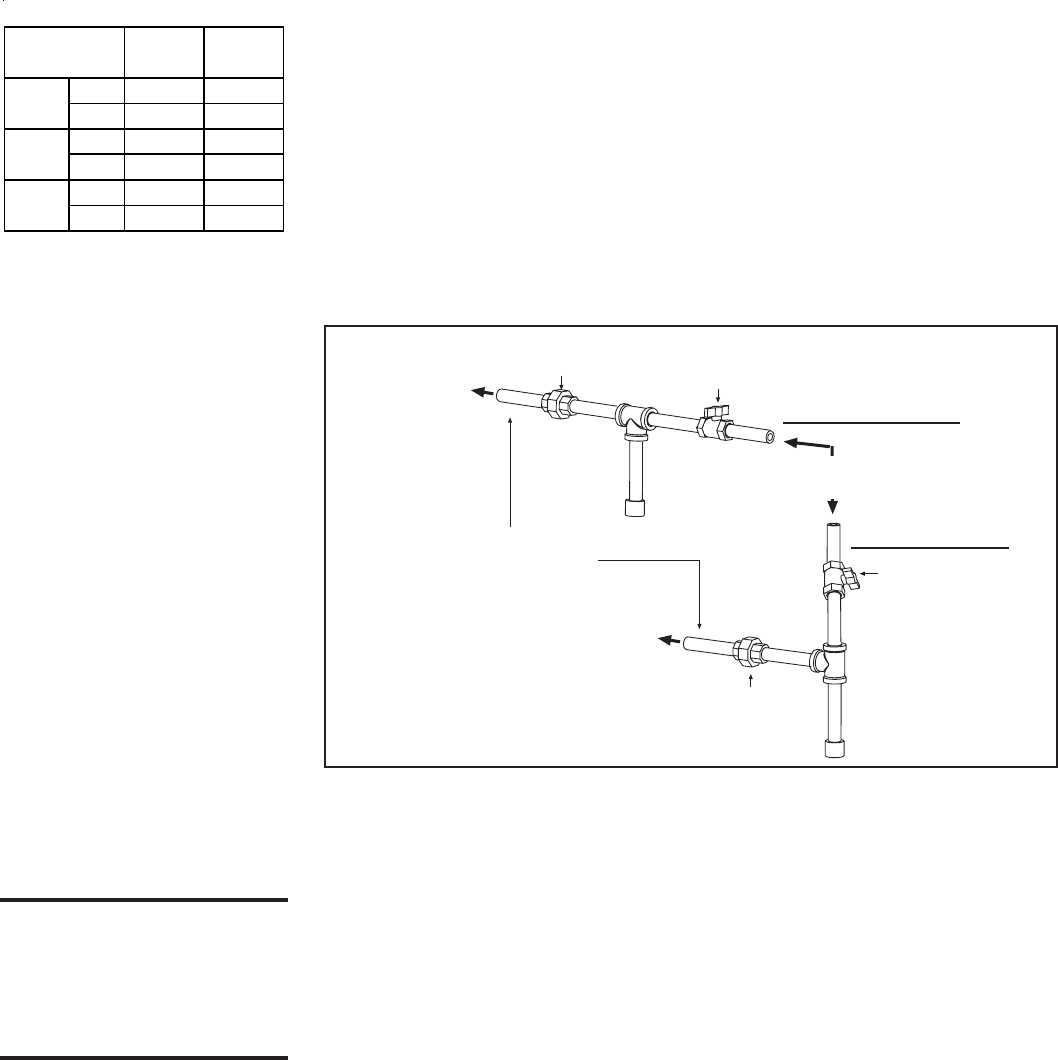

FIGURE 7 - Gas

connection is at the pipe

nipple that extends outside

the cabinet.

IMPORTANT: Two pipe

wrenches are required when

installing gas piping. The gas

pipe that is supplied with the

heater MUST be held with a

pipe wrench to prevent damage

to the heater.

From Gas Supply

(horizontal or vertical)

Manual

shutoff

Pipe nipple extending

outside the cabinet.

Drip

Leg

To Gas Valve

(inside the

cabinet)

To Gas Valve

(inside the

cabinet)

Ground

Joint

Union

Drip

Leg

Ground

Joint Union

Manual shutoff

Horizontal Supply

Vertical Supply

Gas Connection Size

All piping must be in accordance with requirements outlined in the National Fuel

Gas Code ANSI/Z223.1a (latest edition) or CSA-B149.1 and B149.2 (See Paragraph

2). Gas supply piping installation should conform with good practice and with local

codes. Support gas piping with pipe hangers, metal strapping, or other suitable mate-

rial; do not rely on the heater to support the gas pipe.

The heater is orificed for operation with natural gas having a heating value of 1000

(± 50) BTUH per cubic ft or propane gas with a heating value of 2500 (± 100) BTUH

per cubic ft. If the gas at the installation does not meet these specifications, consult

the factory for proper orificing.

Pipe joint compounds (pipe dope) shall be resistant to the action of liquefied petro-

leum gas or any other chemical constituents of the gas being supplied.

Install a ground joint union and manual shutoff valve upstream of the heater control

system, as shown in FIGURE 7. Installation of a trap with a minimum 3" (76mm)

drip leg is required.

To connect the gas, the heater is equipped with a nipple that extends outside the

cabinet.

Leak-test all connections by brushing on a leak-detecting solution.

Gas Connection - inches/mm

Natural

Ga s

Propane

Ga s

inches

11

mm

25.4 25.4

inches

1-1/4 1-1/4

mm

31.8 31.8

inches

1-1/4 1-1/4

mm

31.8 31.8

Size

400

800

1200

NOTE: Gas Conversion Kits

are available for changing

from propane gas to natural

gas or natural gas to propane

gas. A factory-authorized

conversion kit MUST be

used.