Form RZ-NA-I-LDAP, P/N 207733 (Rev 2), Page 10

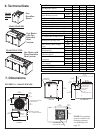

Installing Louvers

NOTE: Do not install louvers

if installing a nozzle. Follow

the instructions shipped with

the nozzle.

Louver Installation Instructions:

1) With the wider section of the louver facing out of the heater, place one of the compres-

sion springs over the tab on the notched end of a louver. The end of the louver with the

spring will fit in any direction in the square opening. How the louver turns depends on

which end of the louver is inserted first.

2) Depending on the throw pattern selected, push the louver tab with the spring into a

hole in the discharge opening and insert the louver tab on the other end into the

corresponding hole on the opposite side.

3) Continue until all louvers are installed.

Adjust the louvers to provide the

desired throw pattern.

Airflow direction;

springs are on

the upper end.

Airflow direction;

springs are on

the lower end.

Wider side of the louver

blade must always be

facing out of the heater.

Compression Spring

FIGURE 6 - Use

Compression Springs to

Install Louvers in the

Discharge Opening(s)

CAUTION: To avoid getting

burned, adjust louvers while

heater is not operating. If

adjusting louvers while

heater is operating, wear

gloves.

After the unit is suspended/mounted, install the air directional louvers or optional

nozzle. If an optional nozzle is being installed, follow the instructions included with

the nozzle. If a nozzle is not being used, install the louvers in the discharge opening(s).

Louvers and springs are in the hardware kit shipped with the heater.

Before actually installing the louvers, note the louver curve and determine how the

louvers should be positioned to provide the optimal throw pattern. Opening is square

so louvers may be installed either horizontal or vertical. Louvers may be installed

with the curve all the same direction (either way) or the right half one way and left

the other as illustrated in FIGURE 6.

Airflow direction depends on

how the louvers are installed.

WARNING: This appliance is equipped for a maximum gas supply

pressure of 1/2 psi, 3.5 kPa, or 14 inches water column. Supply

pressure greater than 1/2 psi requires installation of an additional

lockup-type service regulator external to the heater.

WARNING: PRESSURE TESTING SUPPLY PIPING

Test Pressures Above 1/2 PSI: Disconnect the heater and manual valve from the

gas supply line which is to be tested. Cap or plug the supply line.

Test Pressures Below 1/2 PSI: Before testing, close the manual valve on the heater.

12. Gas Piping

and

Pressures

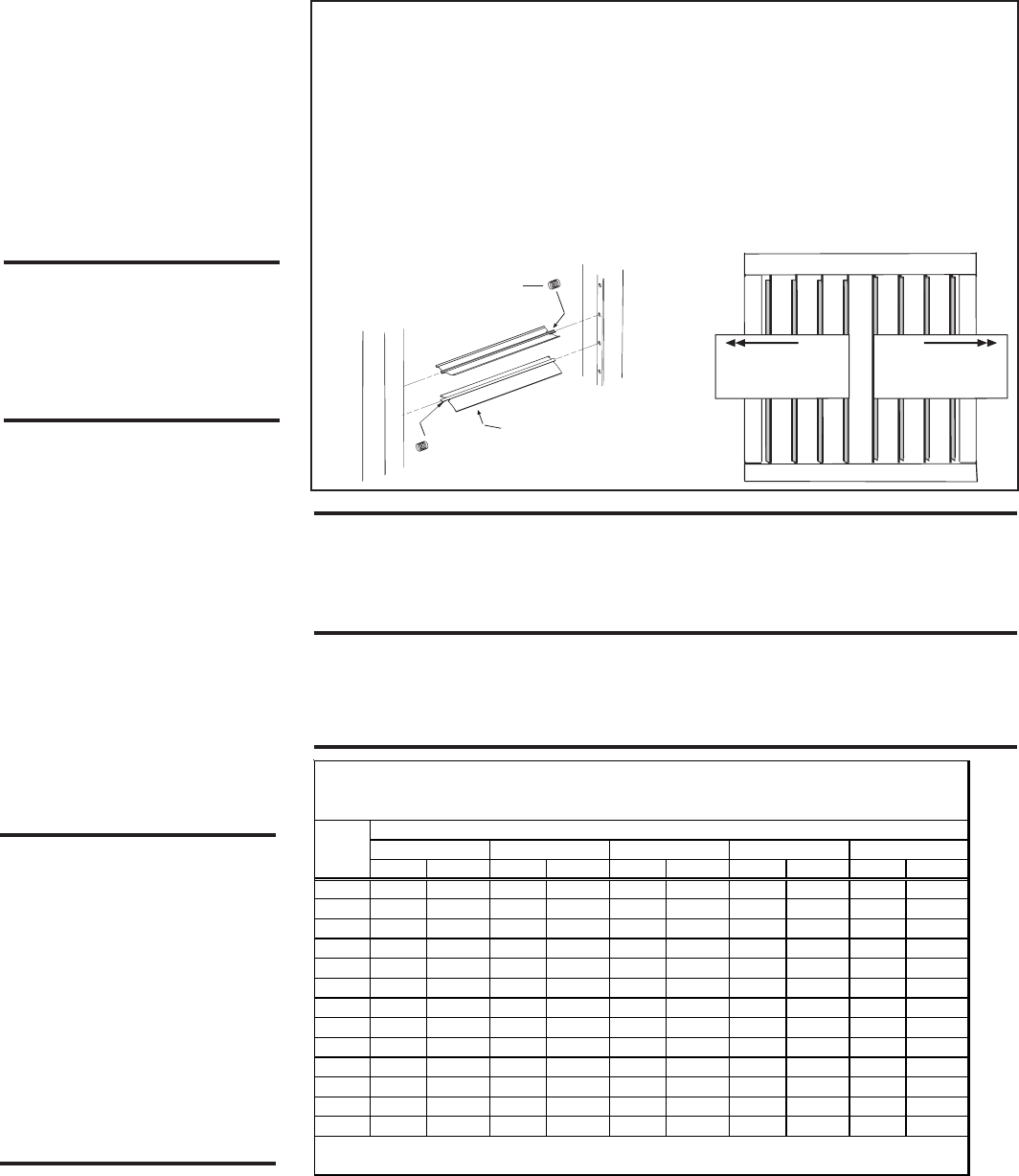

Sizing Gas Supply

Line

Capacity of Piping

- Cubic Feet per Hour based on 0.3" w.c. Pressure Drop

Specific Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specific Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Length Diameter of Pipe

of 1" 1-1/4" 1-1/2" 2" 2-1/2"

Pipe Natura

l

Propane Natural Propane Natura

l

Propane Natura

l

Propane Natural Propane

20' 350 214 730 445 1100 671 2100 1281 3300 2013

30' 285 174 590 360 890 543 1650 1007 2700 1647

40' 245 149 500 305 760 464 1450 885 2300 1403

50' 215 131 440 268 670 409 1270 775 2000 1220

60' 195 119 400 244 610 372 1105 674 1850 1129

70' 180 110 370 226 560 342 1050 641 1700 1037

80' 170 104 350 214 530 323 990 604

1600

976

90' 160 98 320 195 490 299 930 567 1500 915

100' 150 92 305 186 460 281 870 531 1400 854

125' 130 79 275 168 410 250 780 476 1250 763

150' 120 73 250 153 380 232 710 433 1130 689

175' 110 67 225 137 350 214 650 397 1050 641

200' 100 61 210 128 320 195 610 372 980 598

Note: When sizing supply lines, consider possibilities of future expansion and increased requirements.

Refer to National Fuel Gas Code for additional information on line sizing.

WARNING: All com-

ponents of a gas supply

system must be leak

tested prior to placing

equipment in service.

NEVER TEST FOR

LEAKS WITH AN OPEN

FLAME. Failure to

comply could result in

personal injury, property

damage or death.

11. Installing

Heater and

Louvers

(cont’d)