December 15, 2009

7046-137C

Page 7

2700-I ACC Wood Insert

R

Minimum Width of Cavity Opening - Front

2-1/2 775

Minimum Width of Cavity Opening - Rear

20 508

Minimum Height

18-11/16 475

Minimum Depth from Front to Rear

17-1/4 438

Inches Millimeters

The following modications of factory-built replaces are

permissible:

• The replace must not be altered, except that the damper

may be removed to accommodate a direct-connect starter

pipe or chimney liner,

• External trim pieces which do not affect the operation

of the replace may be removed providing they can be

stored on or within the replace for reassembly if the

insert is removed.

• The permanent metal warning label provided in the

component pack must be attached to the back of the

replace, with screws or nails, stating that the replace

may have been altered to accommodate the insert,

and must be returned to original condition for use as a

conventional replace. Figure 37.2.

• If the hearth extension is lower than the replace opening,

the portion of the insert extending onto the hearth must

be supported.

• Manufacturer designed adjustable support kit can be

ordered from your dealer.

• Final approval of this installation type is contingent upon

the authority having jurisdiction.

Damper Smoke Shelf or Bafe

Ember Catches Fire Grate

Viewing Screen/Curtain Doors

Fire Risk.

When lining air-cooled factory-built chimneys:.

• Run chimney liner approved to UL 1777 Type

HT requirements (2100 degrees F)

• Re-install original factory built chimney cap

ONLY

• DO NOT block cooling air openings in chimney

• Blocking cooling air will overheat the chimney

WARNING

Prefabricated Metal Chimney (Cont’d)

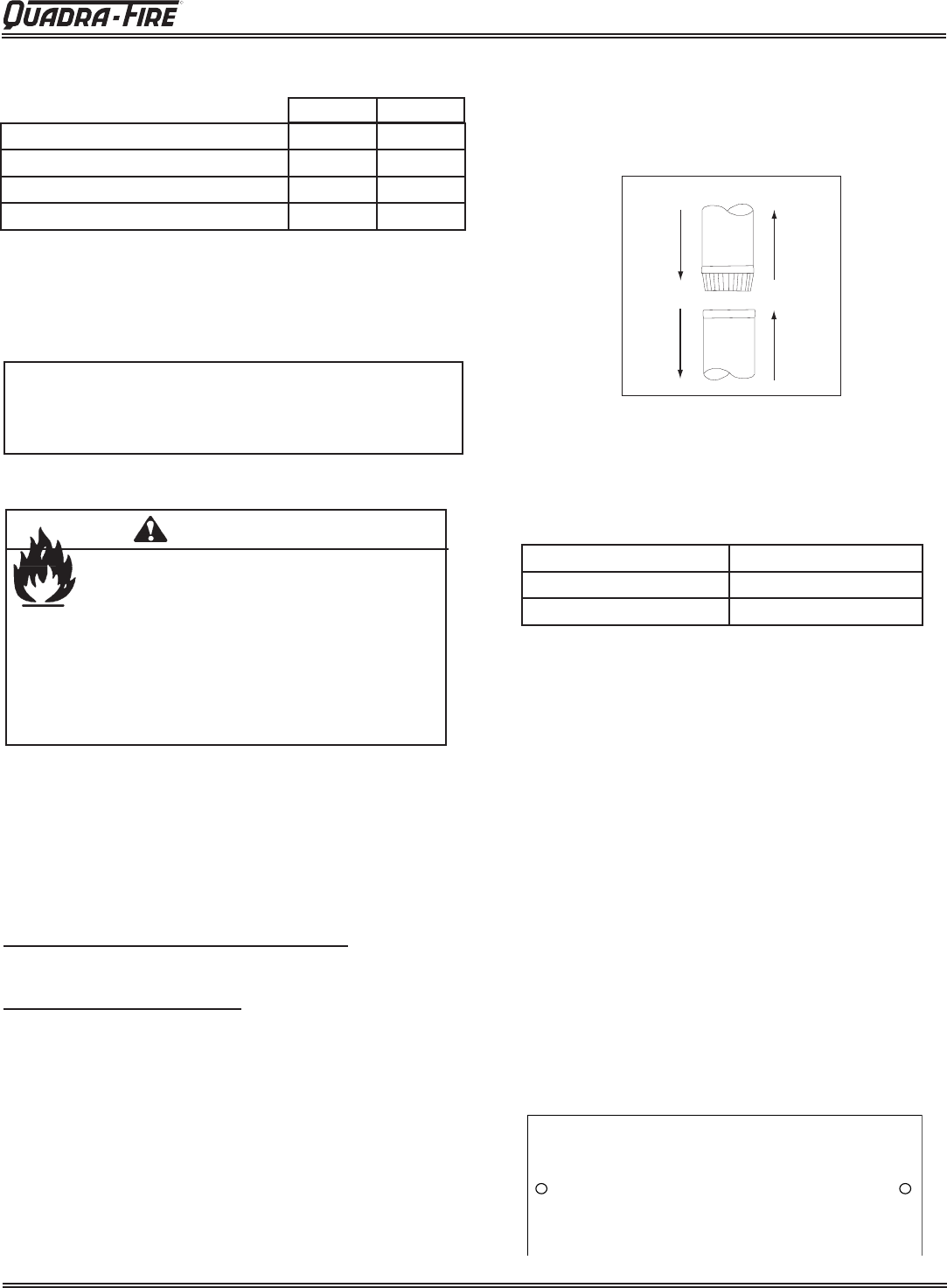

LINER CONNECTOR

FLUE

GAS

DIRECTION

CRIMPED

END

TOWARDS

STOVE

Figure 37.1

NOTICE: In Canada when using a factory-built chimney it must

be safety listed, Type UL103 HT (2100

o

F) [1149

o

C] CLASS

“A” or conforming to CAN/ULC-S629M, STANDARD FOR

650

o

C FACTORY-BUILT CHIMNEYS.

NOTE: Refer to chimney liner manufacturer for recom-

mendations on supporting the liner. Installation into

replaces without a permit will void the listing.

H. Altering the Fireplace

G. Securing Chimney Components

All joints should be secured with sheet metal screws or

rivets per pipe manufacturers instructions. The sections must

be attached to the insert and to each other with the crimped

(male) end pointing toward the insert. Figure 37.1.

WARNING! Risk of Fire!

250-2061

WARNING

THIS FIREPLACE MAY HAVE BEEN ALTERED

TO ACCOMMODATE AN INSERT. IT MUST BE

RETURNED TO ITS ORIGINAL CONDITION

BEFORE USE AS A SOLID FUEL BURNING

FIREPLACE.

250-2061

Figure 37.2

To maintain the functionality of the replace’s chimney

system you may use a Simpson Dura-Vent DuraLiner Slip

Hanger, Part # 4671, and attach to the bottom of the replace

chimney cap to support the liner. You have two options to

completing the installation.

Option one - Not required to use liner cap:

Re-attach the existing top of the chimney cap.

Option two - Using liner cap:

Re-attach the existing top of the chimney cap and install a

new storm collar and a new liner cap.