29

Natural Gas Capacity of Pipe

In Cubic Feet of Gas Per Hour (CFH)

Length of Nominal Black Pipe Size

Pipe in Feet 1/2" 3/4" 1" 1 1/4" 1 1/2"

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 980

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

(Pressure 0.5 psig or less and pressure drop of 0.3" W.C.; Based on

0.60 Specific Gravity Gas)

CFH =

BTUH Furnace Input

Heating Value of Gas (BTU/Cubic Foot)

To connect the furnace to the building’s gas piping, the installer must

supply a ground joint union, drip leg, manual shutoff valve, and line and

fittings to connect to gas valve. In some cases, the installer may also

need to supply a transition piece from 1/2" pipe to a larger pipe size.

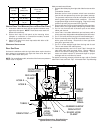

The following stipulations apply when connecting gas piping. Refer to

Gas Piping Connections figure for typical gas line connections to the

furnace.

• Gas piping must be supported external to the furnace cabinet

so that the weight of the gas line does not distort the burner

rack, manifold or gas valve.

• Use black iron or steel pipe and fittings for building piping.

Where possible, use new pipe that is properly chamfered,

reamed, and free of burrs and chips. If old pipe is used, be

sure it is clean and free of rust, scale, burrs, chips, and old

pipe joint compound.

• Use pipe joint compound on male threads ONLY. Always

use pipe joint compound (pipe dope) that is APPROVED

FOR ALL GASES. DO NOT apply compound to the first two

threads.

• Use ground joint unions.

• Install a drip leg to trap dirt and moisture before it can enter

the gas valve. The drip leg must be a minimum of three

inches long.

• Install a 1/8" NPT pipe plug fitting, accessible for test gauge

connection, immediately upstream of the gas supply

connection to the furnace.

• Always use a back-up wrench when making the connection

to the gas valve to keep it from turning. The orientation of

the gas valve on the manifold must be maintained as

shipped from the factory. Maximum torque for the gas valve

connection is 375 in-lbs; excessive over-tightening may

damage the gas valve.

• Install a manual shutoff valve between the gas meter and

unit within six feet of the unit. If a union is installed, the

union must be downstream of the manual shutoff valve,

between the shutoff valve and the furnace.

• Tighten all joints securely.

• Connect the furnace to the building piping by one of the

following methods:

– Rigid metallic pipe and fittings.

– Semi-rigid metallic tubing and metallic fittings.

Aluminum alloy tubing must not be used in exterior

locations. In order to seal the grommet cabinet penetration,

rigid pipe must be used to reach the outside of the cabinet.

A semi-rigid connector to the gas piping may be used from

there.

• Use listed gas appliance connectors in accordance with their

instructions. Connectors must be fully in the same room as

the furnace.

• Protect connectors and semi-rigid tubing against physical and

thermal damage when installed. Ensure aluminum-alloy tubing

and connectors are coated to protect against external corrosion

when in contact with masonry, plaster, or insulation, or subjected

to repeated wetting by liquids such as water (except rain water),

detergents, or sewage.

MANUAL

SHUT OFF VALVE

(UPSTREAM FROM

PIPE UNION)

GROMMET

IN STANDARD

GAS LINE HOLE

GAS LINE

GROMMET IN

GAS LINE

HOLE

HEIGHT REQUIRED

BY LOCAL CODE

PIPE

UNION

DRIP LEG

MANIFOLD

BURNERSGAS VALVE

ALTERNATE

UNION

LOCATION

GROMMET IN

ALTERNATE

GAS LINE

HOLE

DRIP LEG

BURNERS

GAS VALVE