Application – All Motors

WARNING: To prevent accidental electrocution,

automatic or manual transfer switches must be used

any time a generator is used as standby or back

up on power lines. Contact power company for use

and approval.

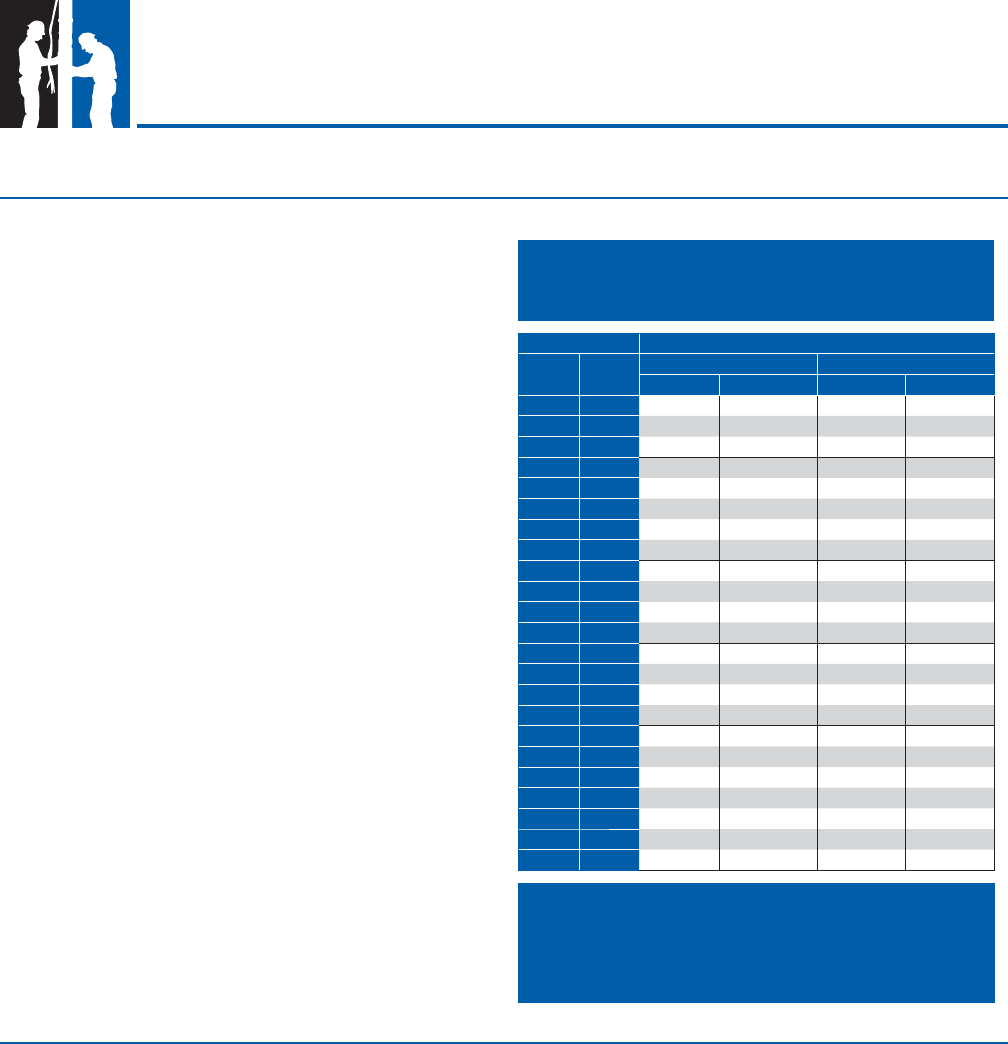

Table 5 lists minimum generator sizes based on typical

80 °C rise continuous duty generators, with 35%

maximum voltage dip during starting, for Franklin’s three-

wire motors, single- or three-phase.

This is a general chart. The generator manufacturer

should be consulted whenever possible, especially on

larger sizes.

There are two types of generators available: externally

and internally regulated. Most are externally regulated.

They use an external voltage regulator that senses the

output voltage. As the voltage dips at motor start-up, the

regulator increases the output voltage of the generator.

Internally regulated (self-excited) generators have an

extra winding in the generator stator. The extra winding

senses the output current to automatically adjust the

output voltage.

Generators must be sized to deliver at least 65% of the

rated voltage during starting to ensure adequate starting

torque. Besides sizing, generator frequency is important

as the motor speed varies with the frequency (Hz). Due

to pump affi nity laws, a pump running at 1 to 2 Hz below

motor nameplate frequency design will not meet its

performance curve. Conversely, a pump running at 1 to 2

Hz above may trip overloads.

Generator Operation

Always start the generator before the motor is started

and always stop the motor before the generator is shut

down. The motor thrust bearing may be damaged if

the generator is allowed to coast down with the motor

running. This same condition occurs when the generator

is allowed to run out of fuel.

Follow generator manufacturer’s recommendations for

de-rating at higher elevations or using natural gas.

It is recommended that one or more check valves always

be used in submersible pump installations. If the pump

does not have a built-in check valve, a line check valve

should be installed in the discharge line within 25 feet

of the pump and below the draw down level of the water

supply. For deeper settings, check valves should be

installed per the manufacturer’s recommendations. More

than one check valve may be required, but more than the

recommended number of check valves should not

be used.

Swing type check valves are not acceptable and should

never be used with submersible motors/pumps. Swing

type check valves have a slower reaction time which can

cause water hammer (see next page). Internal pump

check valves or spring loaded check valves close quickly

and help eliminate water hammer.

Check valves are used to hold pressure in the system

when the pump stops. They also prevent backspin, water

hammer and upthrust. Any of these can lead to early

pump or motor failure.

NOTE: Only positive sealing check valves should be

used in submersible installations. Although drilling the

check valves or using drain-back check valves may

prevent back spinning, they create upthrust and water

hammer problems.

A. Backspin - With no check valve or a failed check

valve, the water in the drop pipe and the water in the

system can fl ow down the discharge pipe when the

motor stops. This can cause the pump to rotate in

a reverse direction. If the motor is started while it is

backspinning, an excessive force is placed across

the pump-motor assembly that can cause impeller

damage, motor or pump shaft breakage, excessive

bearing wear, etc.

B. Upthrust - With no check valve, a leaking check

valve, or drilled check valve, the unit starts under

Use of Engine Driven Generators - Single-Phase or Three-Phase

Table 5 Engine Driven Generators

MOTOR RATING MINIMUM RATING OF GENERATOR

HP KW

EXTERNALLY REGULATED INTERNALLY REGULATED

KW KVA KW KVA

1/3 0.25

1.5 1.9 1.2 1.5

1/2 0.37

2 2.5 1.5 1.9

3/4 0.55

3 3.8 2 2.5

1 0.75

4 5.0 2.5 3.13

1.5 1.1

5 6.25 3 3.8

2 1.5

7.5 9.4 4 5

3 2.2

10 12.5 5 6.25

5 3.7

15 18.75 7.5 9.4

7.5 5.5

20 25.0 10 12.5

10 7.5

30 37.5 15 18.75

15 11

40 50 20 25

20 15

60 75 25 31

25 18.5

75 94 30 37.50

30 22

100 125 40 50

40 30

100 125 50 62.5

50 37

150 188 60 75

60 45

175 220 75 94

75 55

250 313 100 125

100 75

300 375 150 188

125 90

375 469 175 219

150 110

450 563 200 250

175 130

525 656 250 313

200 150

600 750 275 344

Use of Check Valves

NOTE: This chart applies to 3-wire or 3-phase

motors. For best starting of 2-wire motors, the

minimum generator rating is 50% higher than shown.

5