Application – Three-Phase Motors

1

50

= 0.02 or 2%

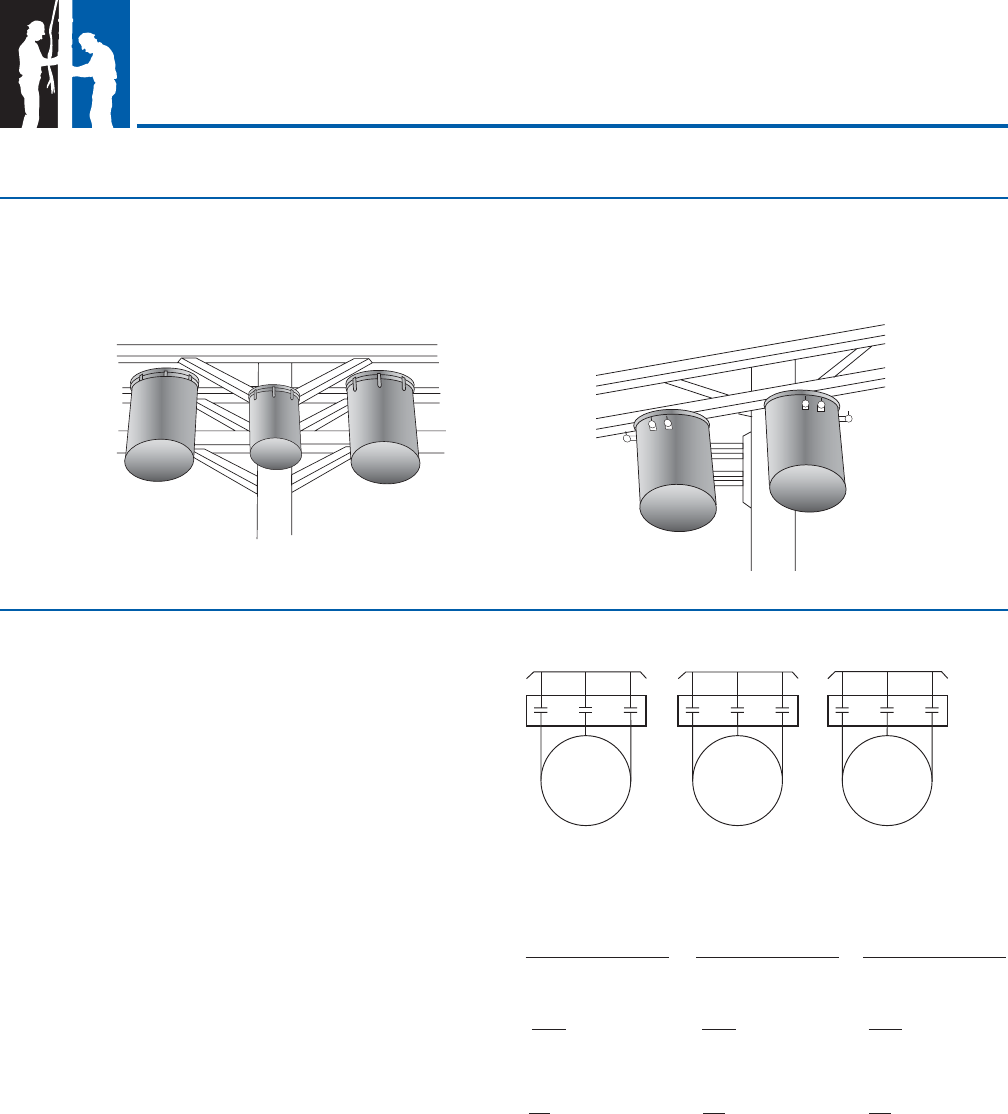

A full three-phase supply is recommended for all three-

phase motors, consisting of three individual transformers

or one three-phase transformer. So-called “open” delta

or wye connections using only two transformers can be

used, but are more likely to cause problems, such as

poor performance, overload tripping or early motor failure

due to current unbalance.

Transformer rating should be no smaller than listed in

table 4 for supply power to the motor alone.

1. Established correct motor rotation by running in both

directions. Change rotation by exchanging any two

of the three motor leads. The rotation that gives the

most water fl ow is always the correct rotation.

2. After correct rotation has been established, check the

current in each of the three motor leads and calculate

the current unbalance as explained in 3 below.

If the current unbalance is 2% or less, leave the leads

as connected.

If the current unbalance is more than 2%, current

readings should be checked on each leg using each

of three possible hook-ups. Roll the motor leads

across the starter in the same direction to prevent

motor reversal.

3. To calculate percent of current unbalance:

A. Add the three line amps values together.

B. Divide the sum by three, yielding average

current.

C. Pick the amp value which is furthest from the

average current (either high or low).

D. Determine the difference between this amp

value (furthest from average) and the average.

E. Divide the difference by the average. Multiply the

result by 100 to determine percent of unbalance.

4. Current unbalance should not exceed 5% at service

factor load or 10% at rated input load. If the unbalance

cannot be corrected by rolling leads, the source of

the unbalance must be located and corrected. If,

on the three possible hookups, the leg farthest from

the average stays on the same power lead, most

of the unbalance is coming from the power source.

However, if the reading farthest from average moves

with the same motor lead, the primary source of

unbalance is on the “motor side” of the starter. In this

instance, consider a damaged cable, leaking splice,

poor connection, or faulty motor winding.

Checking and Correcting Rotation and Current Unbalance

T2

T1

T3

L1

L2

L3

T1

T3

T2

L1

L2

L3

T3

T2

T1

L1

L2

L3

1st Hook Up 2nd Hook Up 3rd Hook Up

supply

starter

motor

EXAMPLE:

T1 = 51 amps T3 = 50 amps T2 = 50 amps

T2 = 46 amps T1 = 49 amps T3 = 48 amps

T3 = 53 amps T2 = 51 amps T1 = 52 amps

Total = 150 amps Total = 150 amps Total = 150 amps

+

+

+

50 - 46 = 4 amps 50 - 49 = 1 amp 50 - 48 = 2 amps

2

50

= 0.04 or 4%

Phase designation of leads for CCW rotation viewing

shaft end.

To reverse rotation, interchange any two leads.

Phase 1 or “A” - Black, T1, or U1

Phase 2 or “B” - Yellow, T2, or V1

Phase 3 or “C” - Red, T3, or W1

NOTICE: Phase 1, 2 and 3 may not be L1, L2 and L3.

FIG. 10

FULL THREE-PHASE

FIG. 11

OPEN DELTA

150

3

= 50 amps

150

3

= 50

amps

4

50

= 0.08 or 8%

150

3

= 50 amps

Three-Phase Power Unbalance

33