Application – All Motors

EXAMPLE: A 6" pump end requiring 39 hp input will

pump 124 °F water in an 8" well at a delivery rate of 140

gpm. From table 7A, a 6" fl ow sleeve will be required to

increase the fl ow rate to at least 3 ft/s

Using table 8, the 1.62 heat factor multiplier is selected

because the hp required is over 30 hp and water

3. Multiply the pump horsepower required by

the heat factor multiplier from table 8.

4. Select a rated hp motor on table 8A whose

Service Factor Horsepower is at least the

value calculated in Item 3.

Hot Water Applications - Example

temperature is above 122 °F. Multiply 39 hp x 1.62

(multiplier), which equals 63.2 hp. This is the minimum

rated service factor horsepower usable at 39 hp in 124 °F.

Using table 8A, select a motor with a rated service factor

horsepower above 63.2 hp. A 60 hp motor has a service

factor horsepower of 69, so a 60 hp motor may be used.

Table 8 Heat Factor Multiplier at 3 ft/s (.91 m/sec) Flow Rate

Table 8A Service Factor Horsepower

2. Determine pump horsepower required

from the pump manufacturer’s curve.

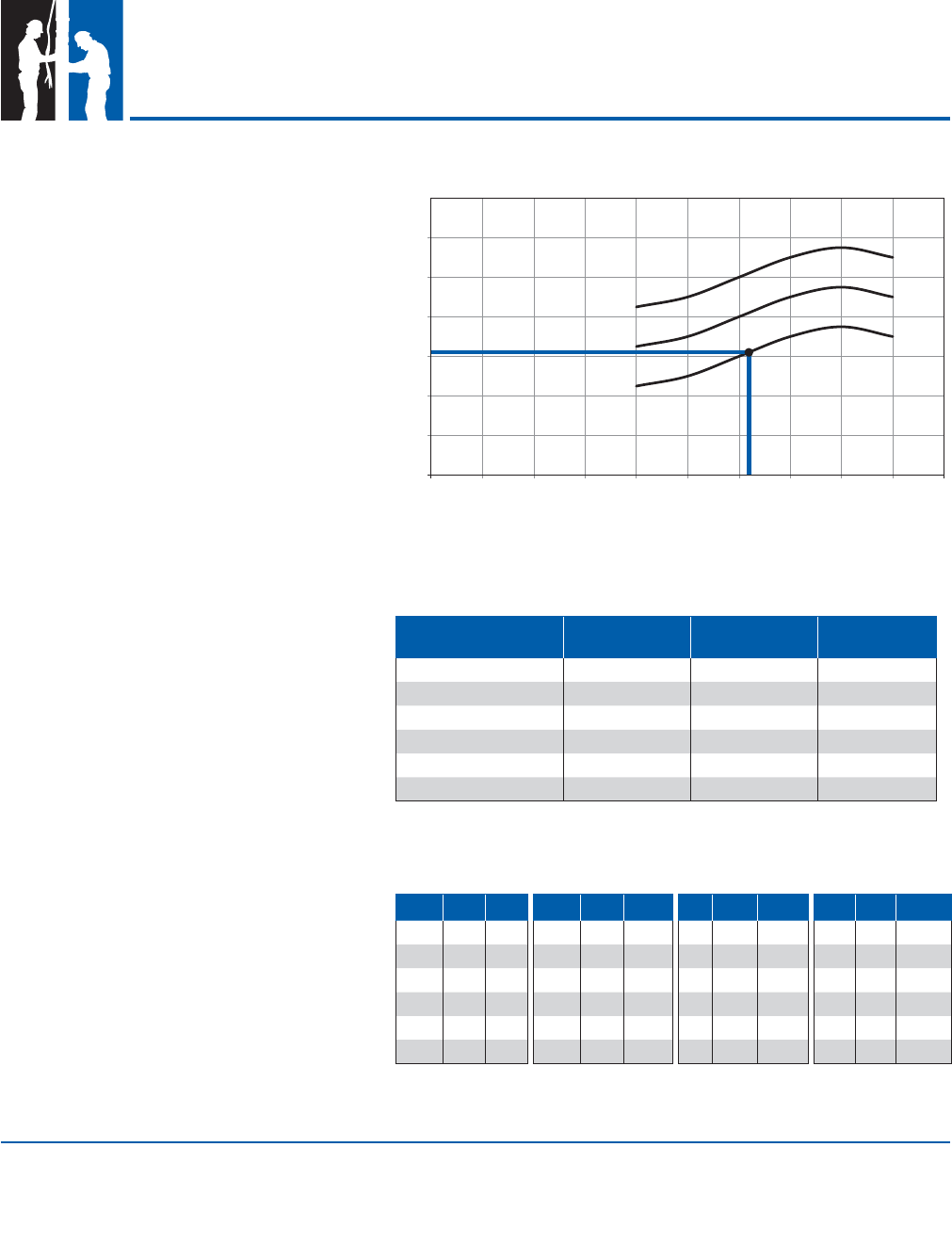

FIG. 2 MANUFACTURER’S PUMP CURVE

0

0 5 10 15 20 25 30 35 40 45 50

Gallons Per Minute

Brake Horsepower

1

2

3

4

5

6

A

B

C

EXAMPLE

MAXIMUM

WATER TEMPERATURE

1/3 - 5 HP

.25 - 3.7 KW

7 1/2 - 30 HP

5.5 - 22 KW

OVER 30 HP

OVER 22 KW

140 °F (60 °C) 1.25 1.62 2.00

131 °F (55 °C) 1.11 1.32 1.62

122 °F (50 °C) 1.00 1.14 1.32

113 °F (45 °C) 1.00 1.00 1.14

104 °F (40 °C) 1.00 1.00 1.00

95 °F (35 °C) 1.00 1.00 1.00

HP KW SFHP HP KW SFHP HP KW SFHP HP KW SFHP

1/3 0.25 0.58 3 2.2 3.45 25 18.5 28.75 100 75 115.00

1/2 0.37 0.80 5 3.7 5.75 30 22.0 34.50 125 90 143.75

3/4 0.55 1.12 7.5 5.5 8.62 40 30.0 46.00 150 110 172.50

1 0.75 1.40 10 7.5 11.50 50 37.0 57.50 175 130 201.25

1.5 1.10 1.95 15 11.0 17.25 60 45.0 69.00 200 150 230.00

2 1.50 2.50 20 15.0 23.00 75 55.0 86.25

8