Application – Three-Phase Motors

Design And Operational Requirements

1. Non-Vertical Operation: Vertical Shaft-up (0°) to

Horizontal (90°) operation is acceptable as long as

the pump transmits “down-thrust” to the motor within

3 seconds after start-up and continuously during

operation. However, it is best practice to provide a

positive slope whenever it is possible, even if it is only

a few degrees.

2. Motor, Sleeve, and Pump Support System: The

booster sleeve ID must be sized according to the

motor cooling and pump NPSHR requirements. The

support system must support the motor’s weight,

prevent motor rotation and keep the motor and pump

aligned. The support system must also allow for

thermal axial expansion of the motor without creating

binding forces.

3. Motor Support Points: A minimum of two support

points are required on the motor. One in the motor/

pump fl ange connection area and one in the bottom

end of the motor area. The motor castings, not the

shell area, are recommended as support points. If the

support is a full length support and/or has bands in

the shell area, they must not restrict heat transfer or

deform the shell.

4. Motor Support Material and Design: The support

system shall not create any areas of cavitation or

other areas of reduced fl ow less than the minimum

rate required by this manual. They should also be

designed to minimize turbulence and vibration and

provide stable alignment. The support materials and

locations must not inhibit the heat transfer away from

the motor.

5. Motor and Pump Alignment: The maximum

allowable misalignment between the motor, pump,

and pump discharge is 0.025 inch per 12 inches of

length (2 mm per 1000 mm of length). This must be

measured in both directions along the assembly using

the motor/pump fl ange connection as the starting

point. The booster sleeve and support system must

be rigid enough to maintain this alignment during

assembly, shipping, operation and maintenance.

6. The best motor lubrication and heat resistance is

obtained with the factory based propylene glycol

fi ll solution. Only when an application MUST HAVE

deionized (DI) water should the factory fi ll solution

be replaced. When a deionized water fi ll is required,

the motor must be derated as indicated on the below

chart. The exchange of the motor fi ll solution to DI

Inline Booster Pump Systems (continued)

water must be done by an approved Franklin service

shop or representative using a vacuum fi ll system

per Franklin’s Motor Service Manual instruction. The

motor shell then must be permanently stamped with a

D closely behind the Serial Number.

The maximum pressure that can be applied to the

motor internal components during the removal of the

factory fi ll solution is 7 psi (0.5 bar.)

First: Determine maximum Feed Water Temperature

that will be experienced in this application. If the

feed water exceeds the maximum ambient of the

motor, both the DI water derating and a hot water

application derating must be applied.

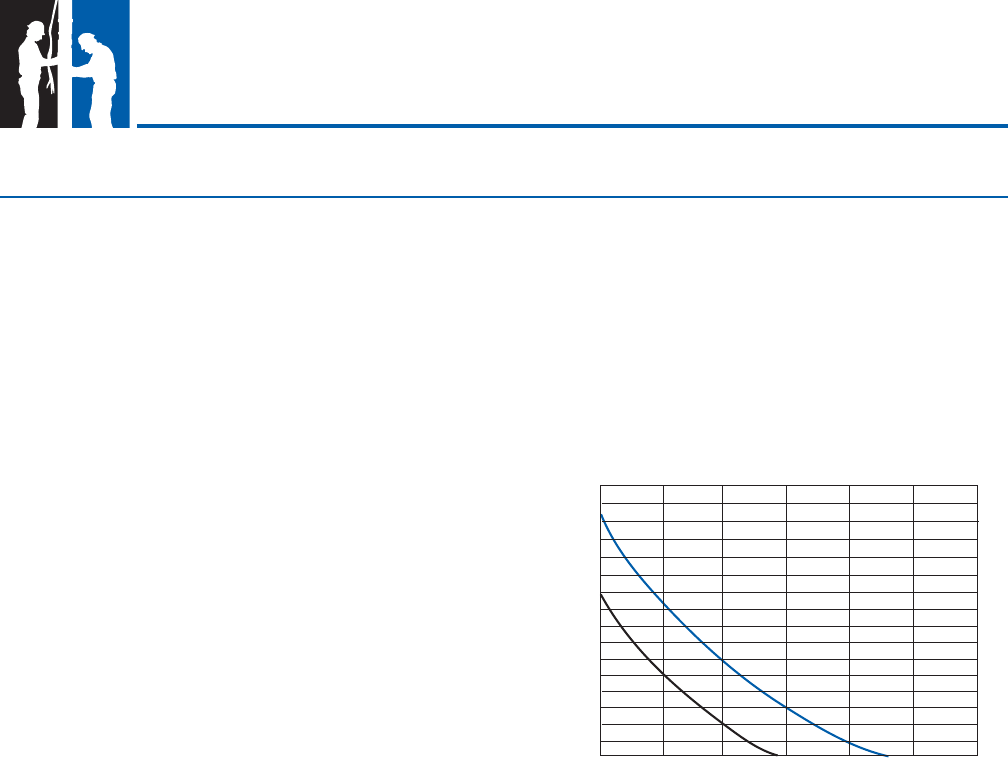

Second: Determine the Pump Load Multiplier from the

appropriate Service Factor curve. (Typical 1.15

Service Factor is for 60 Hz ratings &1.00 Service

Factor for 50 Hz ratings).

Third: Multiply the Pump Load Requirement times the pump

load multiplier number indicated on the vertical axis

to determine the Minimum Motor Nameplate Rating.

Fourth: Select a motor with a nameplate equal or higher than

the above calculated value.

7. Motor Alterations - Sand Slinger & Check Valve

Plug: On 6" and 8" motors, the rubber sand slinger

located on the shaft must be removed. The pipe plug

covering the check valve must be removed from Ni-

resist and 316 SS motors. The special Booster motor

already has these alterations made.

8. Frequency of Starts: Fewer than 10 starts per

24-hour period are recommended. Allow at least 20

minutes between shutdown and start-up of the motor.

FIG. 12

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1

30 25 20 15 10

35

40

1.75

1.65

1.55

1.45

1.35

1.25

1.15

1.05

1.00 Service Factor (50Hz)

1.15 Service Factor (60Hz)

Derating Factor for Motors That Must Have Their Factory Fill

Replaced With Deionized Water 8" Encapsulated Motor

Feed Water Temperature (°C)

Pump Load Multiplier

36