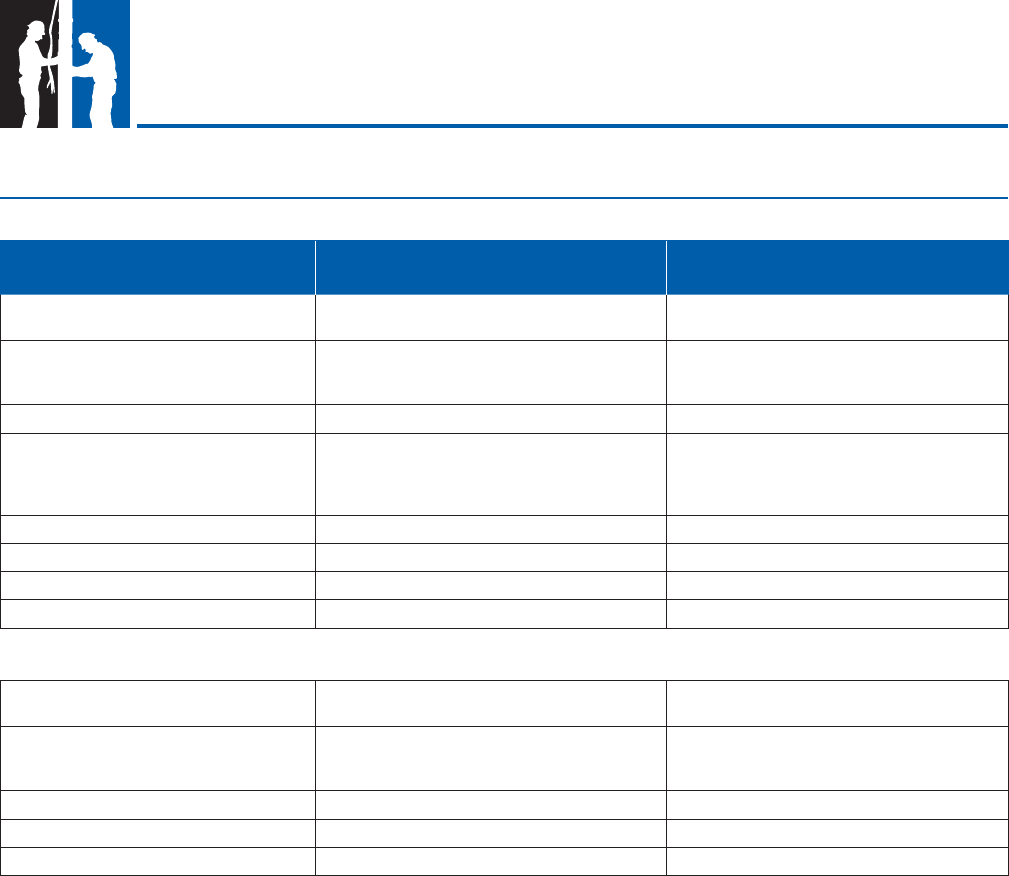

Maintenance – All Motors

System Troubleshooting

POSSIBLE CAUSE CHECKING PROCEDURES CORRECTIVE ACTION

A. Pressure switch.

Check switch for welded contacts.

Check switch adjustments.

Clean contacts, replace switch, or adjust setting.

B. Low water level in well.

Pump may exceed well capacity. Shut off

pump, wait for well to recover. Check

static and drawdown level from well head.

Throttle pump output or reset pump to lower level.

Do not lower if sand may clog pump.

C. Leak in system. Check system for leaks. Replace damaged pipes or repair leaks.

D. Worn pump.

Symptoms of worn pump are similar to

those of drop pipe leak or low water level

in well. Reduce pressure switch setting, if

pump shuts off worn parts may be the fault.

Pull pump and replace worn parts.

E. Loose coupling or broken motor shaft. Check for loose coupling or damaged shaft. Replace worn or damaged parts.

F. Pump screen blocked. Check for clogged intake screen. Clean screen and reset pump depth.

G. Check valve stuck closed. Check operation of check valve. Replace if defective.

H. Control box malfunction. See pages 46-54 for single-phase. Repair or replace.

A. Incorrect voltage.

Using voltmeter, check the line terminals.

Voltage must be within ± 10% of rated voltage.

Contact power company if voltage is incorrect.

B. Overheated protectors.

Direct sunlight or other heat source can raise control

box temperature causing protectors to trip. The box

must not be hot to touch.

Shade box, provide ventilation or move

box away from source.

C. Defective control box. For detailed procedures, see pages 46-54. Repair or replace.

D. Defective motor or cable. For detailed procedures, see pages 44 & 45. Repair or replace.

E. Worn pump or motor. Check running current, see tables 13, 22, 24 & 26. Replace pump and/or motor.

Motor Runs Continuously

Motor Runs But Overload Protector Trips

43