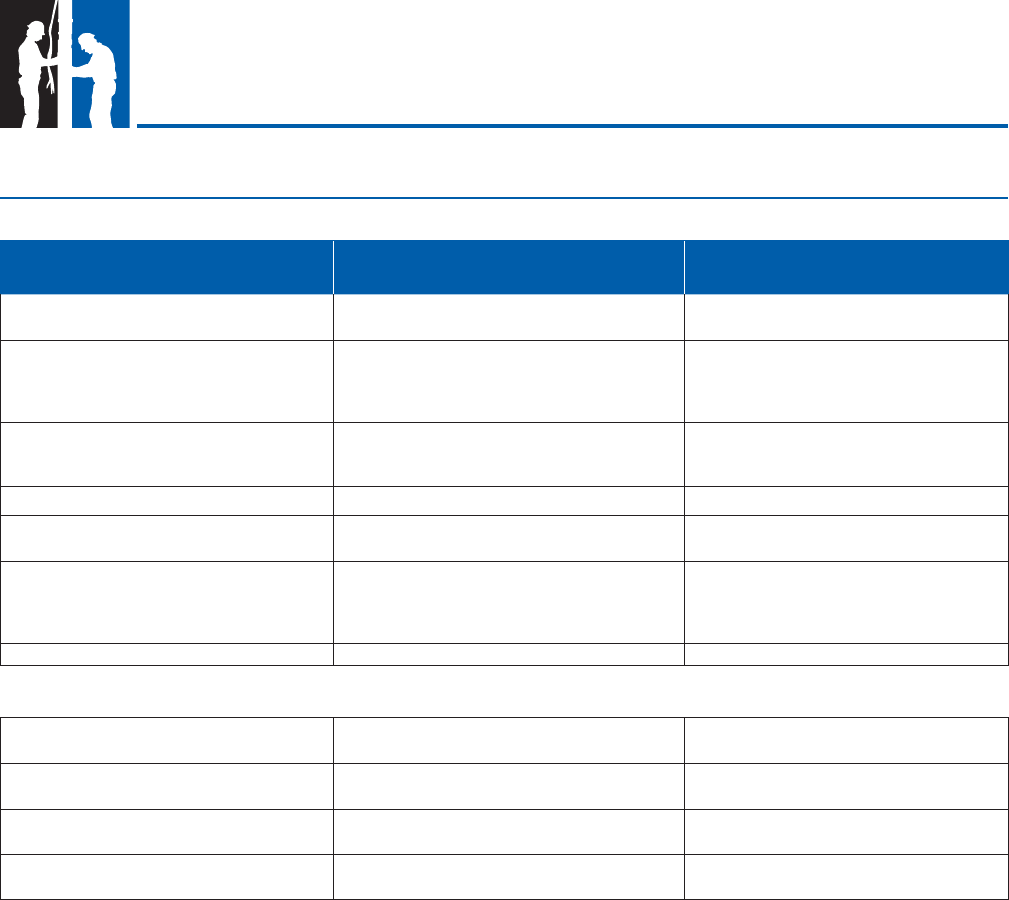

Maintenance – All Motors

System Troubleshooting

POSSIBLE CAUSE CHECKING PROCEDURES CORRECTIVE ACTION

A. No power or incorrect voltage.

Check voltage at line terminals.

The voltage must be ± 10% of rated voltage.

Contact power company if voltage is incorrect.

B. Fuses blown or circuit breakers tripped.

Check fuses for recommended size and

check for loose, dirty or corroded

connections in fuse receptacle. Check

for tripped circuit breakers.

Replace with proper fuse or reset

circuit breakers.

C. Defective pressure switch.

Check voltage at contact points. Improper

contact of switch points can cause voltage

less than line voltage.

Replace pressure switch or clean points.

D. Control box malfunction. For detailed procedure, see pages 46-54. Repair or replace.

E. Defective wiring.

Check for loose or corroded connections

or defective wiring

Correct faulty wiring or connections.

F. Bound pump.

Check for misalignment between pump

and motor or a sand bound pump.

Amp readings will be 3 to 6 times higher

than normal until the overload trips

Pull pump and correct problem. Run new

installation until the water clears

G. Defective cable or motor. For detailed procedure, see pages 44 & 45. Repair or replace.

A. Pressure switch.

Check setting on pressure switch and

examine for defects.

Reset limit or replace switch.

B. Check valve - stuck open.

Damaged or defective check valve will

not hold pressure.

Replace if defective.

C. Waterlogged tank. Check air charge Clean or replace.

D. Leak in system. Check system for leaks. Replace damaged pipes or repair leaks.

Motor Does Not Start

Motor Starts Too Often

42